High Chrome Cast Iron Ball Mill Grinding Balls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

High Chromium Ball Mill Grinding Balls

| Application | Material comminution In cement/Mining/Power Industry |

| Size Range | 10mm-150mm |

| Chromium Percentage | 10%-26% |

| Production Standard | JC-T533-2004 and GB/T17445-2009 |

| Process Method | Cast |

| Microstructurer | M+C |

| Ball Breakage Rate Per Chamber | ≤0.5 |

Product Name | Designation | (HRC) Surface Hardness | Impact Toughness (AK J/cm2) | Microstructure | Specification(mm) |

| High Chromium Alloy Cast Grinding Balls | Cast Cr 26 | ≥59 | ≥3 | Martensite+ Carbide | Ø10, Ø12.7 ,Ø15,Ø17, Ø20 ,Ø25, Ø 30,Ø 35, Ø40, Ø50, Ø 60,Ø 70, Ø80, Ø90,Ø100, Ø110, Ø120 |

| Cast Cr 20 | |||||

| Cast Cr 17 | |||||

| Cast Cr 15 | |||||

| Cast Cr 12 | |||||

| Cast Cr 10 |

We can offer a variety of High Chromium grinding balls with different size and chromium percentage:

Size range from 10mm to 150mm

Chromium percentage from 10 to 26% ,or upon your request.

Grinding Balls Production Line

1.Sand Lined Iron Mold Casting Line,which is Applicable For Producing Grinding Balls With Diameter 40 To 150mm,Average Production Capability 2 Tonne Per Hour.

2.Flaskless Molding Casting Line:Be Suitable For Batch Production Of Casting Grinding Balls With Diameter 10 To 40mm,Casting Grinding Cylpeds With Dimension Range From 6*6mm To 40*45mm,And Even Small Castings.

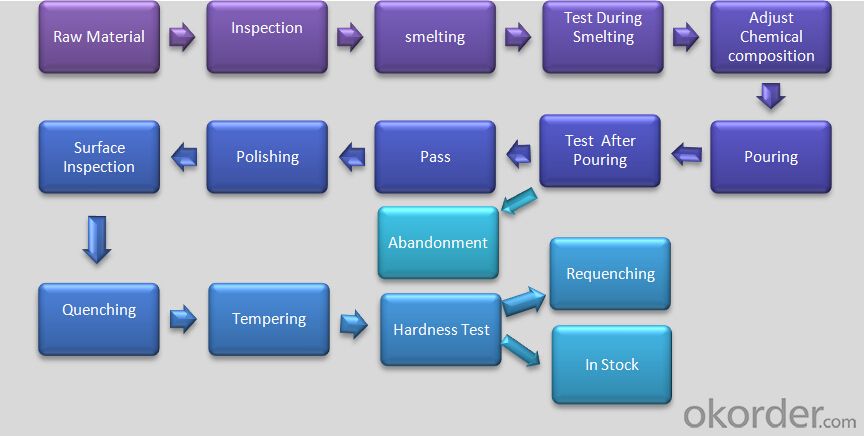

Production Process

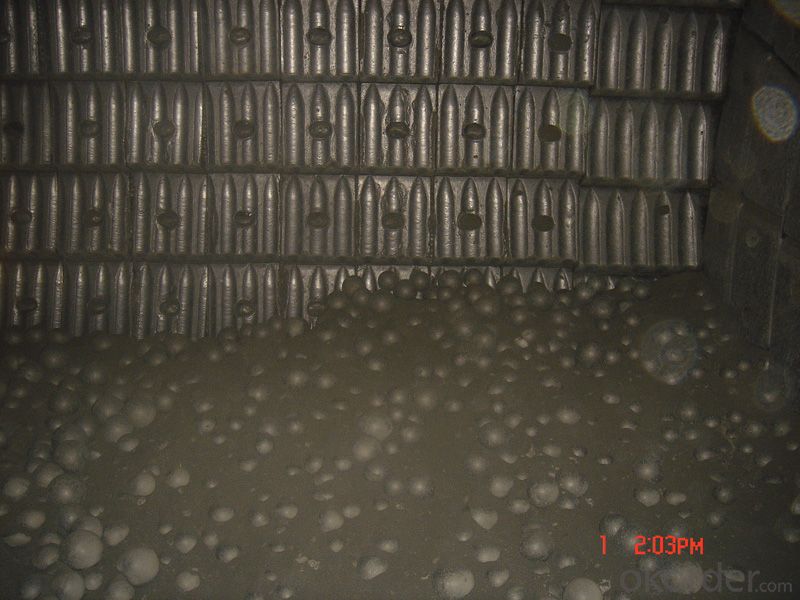

Detailed Images

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Those should be head prints. If required, it would be better to throw with a single grinding head.

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.

- Q: How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q: What are the causes of pitting on the surface of a precision casting?

- There is a bump on the mold. Or casting cooling fast.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: What's the cause of the choking of the casting?,

- 2. when casting mold exhaust condition is not good, in the casting material use consider whether and hinder its gas permeability; in the process to consider to release more pores, multi venting; core exhaust is particularly important.

Send your message to us

High Chrome Cast Iron Ball Mill Grinding Balls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords