Pre-painted steel coil offer from construction companies

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3254 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

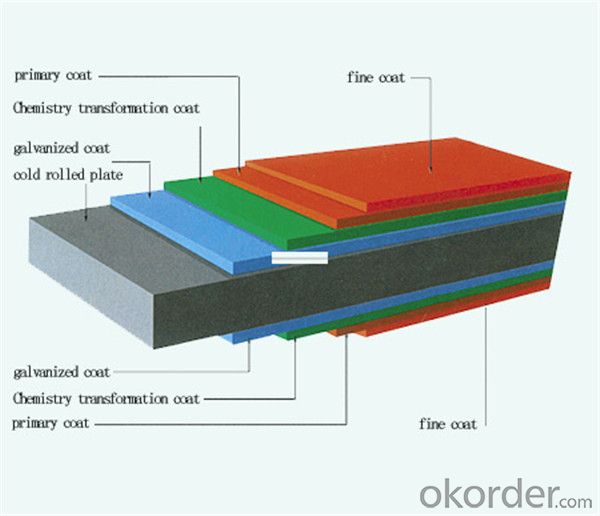

Brief of Product

Product Features

1 Extending service life of products:

Color coating is for protecting steel substrate and for promoting corrosion control effects. Subject to the environment, the different coating combination promotes environmental resisting functions (such as heat resistance, corrosion resistance, humidity resistance, bending resistance, weathering resistance, impact resistance, acid / alkali resistance, chemical resistance and pollution resistance) to offer ultra durability.

2 Better forming ability:

Colors

All types of colors available as per RAL codes mainly White, Red, Blue, Green, Cream, Orange and various others.

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

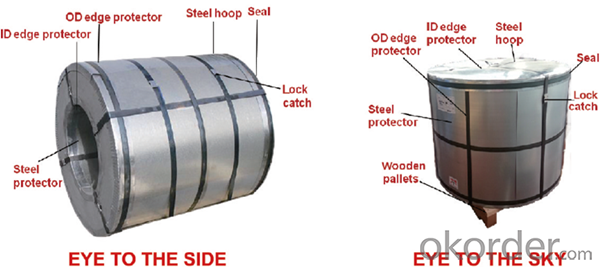

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our service

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: How is steel sustainable as a building material?How is wood sustainable as a building material?

- The choice is yours to make so just click on the proper button for the specific project and then they are right there for you to pick one. The diagrams and instructions will be right there in the computer for you to access at any time or if you prefer you can print them out.

- Q: i see a lot of connexes say repair only with corten steel. what is the difference between corten steel and regular steel. and if i was going to stick weld it what type of electrode would i use?and while i'm at it what is the best electrode to use when welding galvenized steel?

- 6010 and 6011 Electrodes for welding galvenized steel. Weathering steel, best-known under the trademark COR-TEN steel and sometimes written without the hyphen as Corten steel, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. The corrosion-retarding effect of the protective layer is produced by the particular distribution and concentration of alloying elements in it. The layer protecting the surface develops and regenerates continuously when subjected to the influence of the weather. In other words, the steel is allowed to rust in order to form the 'protective' coating. For welding corten steel: 1A.W.S ClassificationE 7018 - 1AWS A 5 - 1 - 78 2IS classificationE 5424 JXIS 814 (Part I II)H 3BS classificationE 51.54 B 12 17HBs 639 - 1976

- Q: i need working shoes for women that have steel toe shoes? What store do they sell them in . i live in c.a.

- Do a search for local safety toe shoes. I have to have them for work also, and as a woman I can't just go to Walmarts. Unfortunately the store I go to is here in Atlanta, so not much help. But there are specialty stores for safety shoes. Brands I like are Hytest and Georgia Boots. Especially the Hytest instead of steel toes which are heavy the toes are kevlar.

- Q: If you keep it dry and clean, what steel will last the longest over the years with continued use and sharpening?

- you eventually will wear the blade out. i have seen old guys pocketknives that they used for whittlin and the blades have deep curves in them like khukris from wear. i reccommend, 440 stainless, or something with a rockwell hardness rating above 45.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various applications. They are commonly used in the production of appliances, automotive parts, construction materials, and packaging materials. The coils can be shaped, cut, and formed into different components or structures, providing strength, durability, and versatility to the end products.

- Q: engineering sloutions related to steel fabrication

- The American Institute of Steel Construction develops codes for steel building design in the U.S. See the link to below to the Steel Solutions Center at their website. You can find free programs for designing structural steel elements from clicking on technical resources at that link. Most of the programs presume that you are a structural/civil engineer with knowledge of the steel design specifications.

- Q: hi, i have a steel block with an unussual composition. does anyone know if this is any particular type?c- .6%, si - .33%, mn - .6%, sulphur - .014%, phosphorous - .013%, ni - 1.69%, Cr, 1.07%, molybdenum - .67%

- You have opened a can of worms. Specific types of steel vary not only by composition but by the way they were made, their physical properties and their morphology (microscopic structure). The composition you have given would fit for High Carbon Steel and Medium Carbon Steel. Go to the reference I've given, it allows you to put in 3 of the components of your alloy and then it gives you a list of possibilities. You can open each candidate individually and see the full composition. Hours of fun. :)

- Q: What are the different types of steel coil surface protection methods?

- There are several types of steel coil surface protection methods, including oiling, painting, galvanizing, and plastic film coating.

- Q: Does Steel Cut Oatmeal have the same health benefits as Old Fashioned Oatmeal? What is the difference in processing?

- I have read about steel cut oatmeal, and they say that has the benefit of the whole natural grain, so its more fiber that your getting for your digestion!

Send your message to us

Pre-painted steel coil offer from construction companies

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3254 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords