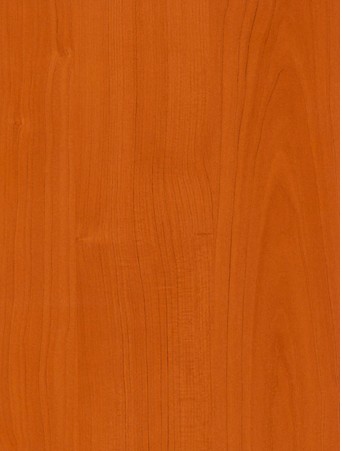

Pre-painted Galvanized Steel Coil-JIS G 3312-wooden pattern2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: What is the maximum temperature that steel coils can withstand?

- The maximum temperature that steel coils can withstand depends on the specific grade and type of steel being used. However, in general, steel coils can withstand temperatures up to around 1,300 to 1,500 degrees Celsius (2,372 to 2,732 degrees Fahrenheit) before they start to lose their structural integrity and develop deformation or other forms of damage.

- Q: What are the common coil loading and unloading procedures?

- Common coil loading procedures involve using cranes or forklifts to lift and position the coil onto a truck or a designated storage area. This process requires careful handling to ensure the coil is properly secured and balanced. Additionally, protective measures such as using steel racks or padding may be employed to prevent damage during transportation. In terms of unloading, the reverse process is followed, with the coil being carefully lifted and placed onto the ground or a designated storage area. Safety precautions are essential during both loading and unloading procedures to minimize the risk of accidents or injuries.

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- Cold rolled steel coils are generally sprayed antirust oil, according to user requirements, light, medium, heavy oil 3 types. Nevertheless, if the oil is volatile or in a humid environment, the steel plate comes into contact with the water for a period of time, indicating that it is beginning to rust.

- Q: All of my friends say that if a car made of mostly carbon fiber would crash into a full steel car, or vice versa, the steel car would be DESTROYED and the carbon fiber would drive away, if not, easily repairable.

- Depends on the design/construction.

- Q: What are the common methods of testing the durability of steel coils?

- Common methods of testing the durability of steel coils include tension tests, impact tests, bending tests, hardness tests, and corrosion tests.

- Q: What are the dimensions and weight range of steel coils?

- Depending on the intended use and industry requirements, steel coils can vary in dimensions and weight ranges. Typically, the thickness of steel coils ranges from 0.15mm to 3.5mm, while their width ranges from 600mm to 2,000mm. The weight range of steel coils can widely vary, commonly falling between 5 and 25 metric tons. Factors such as the type of steel, the production method, and the desired application determine the specific dimensions and weight range of steel coils.

- Q: What are the different methods of corrosion protection for steel coils?

- There are several methods of corrosion protection for steel coils, including but not limited to: 1. Coating: Applying a protective layer such as paint, polymer, or zinc coating on the surface of the steel coil to prevent direct contact with corrosive agents. 2. Galvanizing: Immersing the steel coil in a bath of molten zinc, creating a protective coating that prevents corrosion. 3. VCI (Vapor Corrosion Inhibitor): Using volatile corrosion inhibitors that release molecules to form a protective layer on the steel coil, preventing corrosion. 4. Oil or Wax Coating: Applying a layer of oil or wax on the surface of the steel coil to act as a barrier against moisture and corrosive elements. 5. Cathodic Protection: Using sacrificial anodes or impressed current to protect the steel coil by providing a more easily corroded metal that attracts corrosion instead. 6. Desiccants: Placing desiccant materials such as silica gel or molecular sieves inside the packaging to absorb moisture and prevent corrosion. 7. Environmental Control: Maintaining controlled humidity levels, temperature, and proper ventilation in storage areas to minimize the risk of corrosion. 8. Proper Handling and Storage: Implementing safe handling practices during transportation and storing steel coils in dry, covered areas away from corrosive substances. It is important to select the appropriate method based on the specific application, environment, and desired level of protection for the steel coils.

- Q: Can steel coils be coated with anti-counterfeit materials?

- Yes, steel coils can be coated with anti-counterfeit materials.

- Q: How are steel coils used in the production of wind turbines?

- Steel coils are used in the production of wind turbines to manufacture the tower, nacelle, and other structural components. The coils are processed and shaped to form the required sections, which are then assembled and integrated to create the framework and support structure for the wind turbine. The high strength and durability of steel make it an ideal material for withstanding the demanding conditions and loads experienced by wind turbines.

- Q: Are steel coils used in agricultural equipment manufacturing?

- Yes, steel coils are commonly used in agricultural equipment manufacturing. Steel coils are often used to produce various components and parts for agricultural machinery, such as plows, harvesters, tractors, and tillers. The use of steel coils in agricultural equipment manufacturing ensures durability, strength, and resistance to various environmental conditions, making them essential in this industry.

Send your message to us

Pre-painted Galvanized Steel Coil-JIS G 3312-wooden pattern2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords