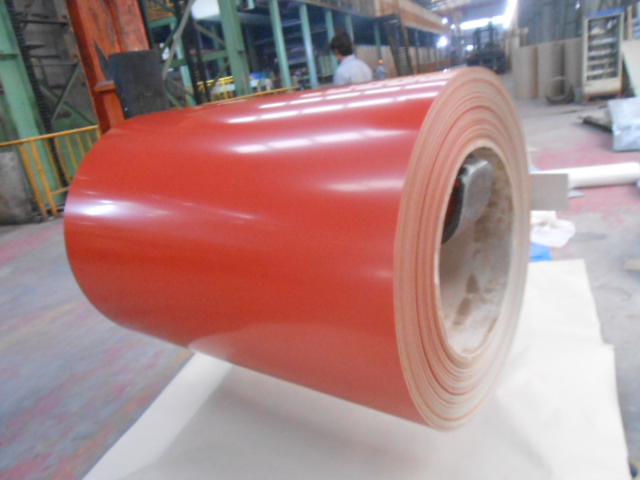

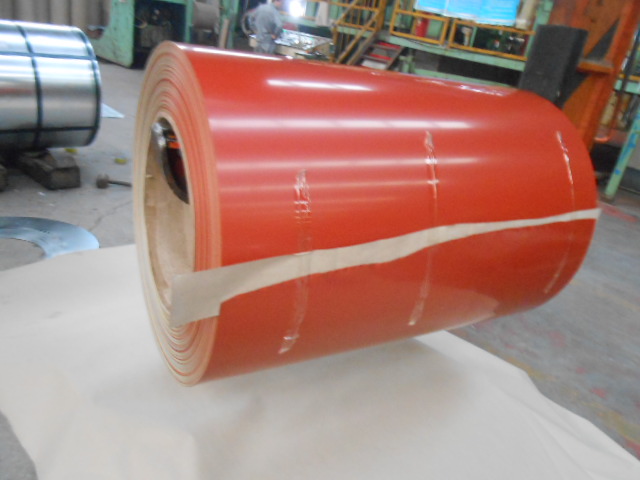

Pre-Painted Galvanized/Aluzinc Steel Sheet in Coil Brick Red 0.25mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of lighting fixtures?

- Steel coils are used in the manufacturing of lighting fixtures primarily for their structural strength and durability. The steel coils are shaped and formed into various components such as brackets, frames, and housings that provide stability and support for the lighting fixtures. Additionally, the steel coils are often coated or plated to enhance their aesthetic appeal and protect against corrosion.

- Q: I live in the Black Hills and I need to re-side my cottage. I like the look of vinyl. I've heard pros and cons about both steel and vinyl. Is steel really that easy to dent? It just doesn't look as 'clean' as vinyl. Also what 3 color combos do you like? My cottage has shutters.

- I'd like to know why you need to re-side it. I would get vinyl because it will not need painting as soon as steel.

- Q: What minerals are mixed to make steel?

- W - weldable steel WT- Weldable Noctch-tough steel R - Atomospheric corrosion-resistant steel A - Atomospheric corrosion-resistant steel weldable steel R - Atomospheric corrosion-resistant steel weldable Notch-tough steel Q- Quenched and tempered Low-alloy Steel QT-Quenched and tempered Low-alloy Steel Notch-tough steel For W and WT: C, Mn, P, S, Si, small quanties Cb,V,Al For R, A, AT: C, Mn, P, S, Si, Cr, Ni, Cu small quanties Cb,V,Al For Q: C, Mn, P, S, Si, Cr, Ni, Cu, and small amounts of boron See CSA G40.21 if you want more info

- Q: Can steel coils be cut or trimmed after delivery?

- Yes, steel coils can be cut or trimmed after delivery using various cutting methods such as shearing, slitting, or laser cutting, depending on the desired specifications and requirements.

- Q: Can steel coils be customized in terms of size and thickness?

- Yes, steel coils can be customized in terms of size and thickness. Manufacturers can produce steel coils in various dimensions and thicknesses to meet specific requirements and applications.

- Q: How are steel coils used in the production of metal signs?

- Steel coils are used in the production of metal signs as they provide a durable and versatile material for creating the sign's base. The coils are unwound and flattened to form sheets, which are then cut into desired shapes and sizes. These steel sheets can be easily manipulated and bent to create the desired design for the sign. Additionally, the strength and resilience of steel make it an ideal material for outdoor signs, as it can withstand harsh weather conditions and maintain its structural integrity over time.

- Q: What are the factors to consider when selecting a supplier for steel coils?

- When selecting a supplier for steel coils, there are a few key factors to consider. Firstly, the quality of the steel coils is crucial. It is important to assess the supplier's reputation, certifications, and track record for delivering high-quality products. Secondly, pricing and cost-effectiveness play a significant role. Comparing prices and negotiating favorable terms with different suppliers is essential to ensure competitive pricing. Additionally, the supplier's reliability and ability to meet delivery schedules must be thoroughly evaluated. Timely delivery is vital to avoid disruptions in production. Lastly, considering the supplier's location, proximity to the manufacturing facility, and their overall customer service and support are also important factors to take into account.

- Q: What are the different types of steel coil surface treatments for outdoor applications?

- There are several different types of steel coil surface treatments that are commonly used for outdoor applications. These treatments are applied to the steel to enhance its durability, corrosion resistance, and appearance. Some of the most commonly used surface treatments for outdoor applications include: 1. Galvanized: Galvanization is a process where a layer of zinc is applied to the steel surface. This treatment provides excellent corrosion resistance, making it ideal for outdoor applications. Galvanized steel coils have a shiny, silver appearance. 2. Galvalume: Galvalume is a combination of aluminum and zinc, which is applied to the steel surface. This treatment provides superior corrosion resistance compared to galvanized steel. Galvalume steel coils have a duller, matte finish. 3. Painted: Steel coils can be painted with a variety of coatings to enhance their appearance and protect against corrosion. The paint can be applied in a single or multiple layers, depending on the desired level of protection. Painted steel coils are available in a wide range of colors and finishes. 4. Powder Coated: Powder coating is a type of paint coating that is applied as a powder and then cured under heat. This treatment creates a durable and long-lasting finish. Powder coated steel coils are resistant to chipping, scratching, and fading, making them suitable for outdoor applications. 5. Organic Coated: Organic coatings, such as PVC or PVDF, are applied to steel coils to provide additional protection against corrosion and weathering. These coatings are typically used in architectural applications where aesthetics and durability are important. These different types of steel coil surface treatments offer various levels of protection and aesthetic options for outdoor applications. The choice of treatment depends on factors such as the intended use, environmental conditions, and desired appearance.

- Q: What are the different types of steel coil edge treatments?

- There are several different types of steel coil edge treatments, including mill edge, slit edge, deburred edge, and rounded edge. Mill edge refers to the original edge of the steel coil as it comes from the mill, which is typically sharp and uneven. Slit edge is a straight and smooth edge created by slitting the coil. Deburred edge is a process of removing any burrs or sharp edges from the coil edge to provide a smoother finish. Rounded edge is a type of edge treatment where the sharp corners of the coil are rounded off to reduce the risk of injury and improve handling.

- Q: How are steel coils used in the manufacturing of doors and windows?

- Steel coils are used in the manufacturing of doors and windows as they provide a strong and durable material for constructing the frames and components. The coils are first processed and cut into the desired shape, then formed and welded together to create the frames. This ensures stability and support, allowing the doors and windows to withstand various weather conditions and provide long-lasting performance.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Sheet in Coil Brick Red 0.25mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords