Pre-Painted Galvanized/Aluzinc Steel Coil -Best Quality in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil -Best Quality in China

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

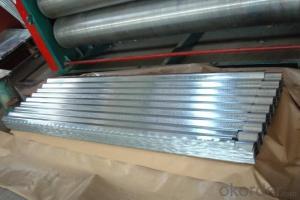

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I'm looking for a good source as to the 'structural formula' of steel. I'm not quite sure if that's what it's actually called, but here's a link to what I'm looking for.

- That's a very good question. What you need to do is run down to your local university and sign up for a undergraduate degree in Civil Engineering and after you finish that (4 to 5 years) then you need to sign up for a masters degree in Structural Engineering (2 to 3 years). Then, get yourself a structural engineering job and in 4 years you will be able to test to become a Professional Engineer. Whew, after that you will get paid very well as a tower designer.

- Q: I have one and wonder how much force this can take since it does seem like you can bend it(Sure it's impossible with hands), but I don't want to try that cause i don't want to break it. Many people say that it's really hard and can handle a hammer smash? is that true and can it even make it through more force. Cause steel is harder than iron and iron is pretty hard... So how much can i trust this locks security, i mean if i put at at a door would some thiefes be able to break it, if they had the right tools??

- It's hard to give you a quantitative answer. There are different grades of testing standards for padlocks. It comes under the ASTM F883. You need to be more specific. The link only gives a picture and no details about the lock. But in general, stainless steel locks are pretty darn strong. Also, you are under the wrong impression about steel vs iron. Iron is a component of steel. Pure iron is very ductile and is softer than steel. Cast iron, is very hard, but is also very brittle and has limited uses. In general, mild steel is realitively soft and ductile. But, there are many different alloys of steel and some have hardnesses and strengths higher than cast iron. Stainless steel is typically more ductile that mild steel because of the smaller amount of iron in the recipe. There are exceptions to that as well. The 400 series of stainless steels have higher amounts of iron and can be heat treated to hardnesses equaling the better steel alloys.

- Q: If needed for Defence could a stainless steel sword kill someone my buddy wanted this sword for Defece after it is sharpend here is a picture

- Stainless steel only works for knives, anything past 12 inches it starts getting brittle, carbon steel is what you are looking for. As far as home defense, if you don't know how to use it, you will be worse off.

- Q: What are the main factors that affect the formability of steel coils?

- The main factors that affect the formability of steel coils are the composition and microstructure of the steel, the thickness and width of the coil, the temperature during forming, and the mechanical properties of the steel.

- Q: Can steel coils be recycled?

- Yes, steel coils can be recycled. Steel is a highly recyclable material, and steel coils can be melted down and reformed into new steel products without losing their quality or strength. Recycling steel coils helps to conserve natural resources, reduce energy consumption, and minimize waste.

- Q: How are steel coils labeled and identified?

- Steel coils are labeled and identified through a variety of methods to ensure proper tracking and handling throughout their journey. The labeling and identification process typically involves the following steps: 1. Manufacturer's Identification: The steel coil is initially marked with the manufacturer's name or logo, allowing for easy identification of the company that produced it. 2. Coil Number: Each steel coil is assigned a unique identification number, commonly referred to as a coil number. This number is often stamped or etched onto the surface of the coil and is used for tracking and inventory purposes. 3. Size and Weight: Steel coils are labeled with their size and weight specifications. This information helps in determining the dimensions and weight capacity of the coil, allowing for appropriate handling and transportation arrangements. 4. Grade and Material: The grade and material composition of the steel coil are typically indicated on the labeling. This provides essential information about the properties and quality of the steel, ensuring it is utilized correctly in manufacturing processes. 5. Heat or Lot Number: Steel coils can also be labeled with a heat or lot number, which refers to the production batch from which the coil originated. This information helps in traceability and quality control, facilitating identification in case of any issues or defects. 6. Barcodes or QR codes: Many steel coils are now labeled with barcodes or QR codes, which can be scanned using automated systems. These codes contain all relevant information about the coil, allowing for efficient data capture and management throughout the supply chain. Proper labeling and identification of steel coils are crucial for effective logistics management, inventory control, and quality assurance. By employing these identification methods, manufacturers, distributors, and end-users can easily track, handle, and utilize steel coils in a safe and efficient manner.

- Q: Are steel coils corrosion-resistant?

- Yes, steel coils can be made corrosion-resistant through various methods such as galvanization or coating them with protective layers.

- Q: y does 1095 steel on a katana weight about a pound less for the same amount than 1045? the 1095 is better right? but then why is 1045 steel more comenly used for practical use than 1095, even though i no its cheaper to use 1045 for tami mats. so is 1095 steel the better investment for buying and minor tami mat use?

- Steel grades generally tell you how much carbon is in the steel. The higher the number the more carbon. Aside from quality of manufacture, the better swords tend to be 1060 or more. Few quality swords are made from 1045. Which DOES NOtT hold an edge better (quite the reverse). Swords made of these different steels weigh about the same. That is, if you made two identical looking swords - one of 1095 the other of 1045, they would weigh the same. 1045 is only more commonly used because cheaper swords tend to be made from it. Edit: No real swords are made from stainless steel.

- Q: where can you find carbon steel in los angeles?? what store?? preferabbly 01 carbon steel

- McMAster-Carr is a good catalog supplier of everything. Shipping for this stuff will be expensive. Talk to steel places near where you live. Carbon steel is not very descriptive. Structural steel is perhaps the most common, it has carbon in it, but people know it as ASTM A36 (36,000 yeild). You might talk to the steel people about your application to see what would be the cheapest for your application.

- Q: Is it possible to make a homemade blacksmith forge from a washing machine drum made of stainless steel?

- This Site Might Help You. RE: Can I make a homemade blacksmith forge from an old stainless steel washing machine drum? Is it possible to make a homemade blacksmith forge from a washing machine drum made of stainless steel?

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil -Best Quality in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords