Pre- painted Galvanized/ Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• nice formability

• Good visual effect

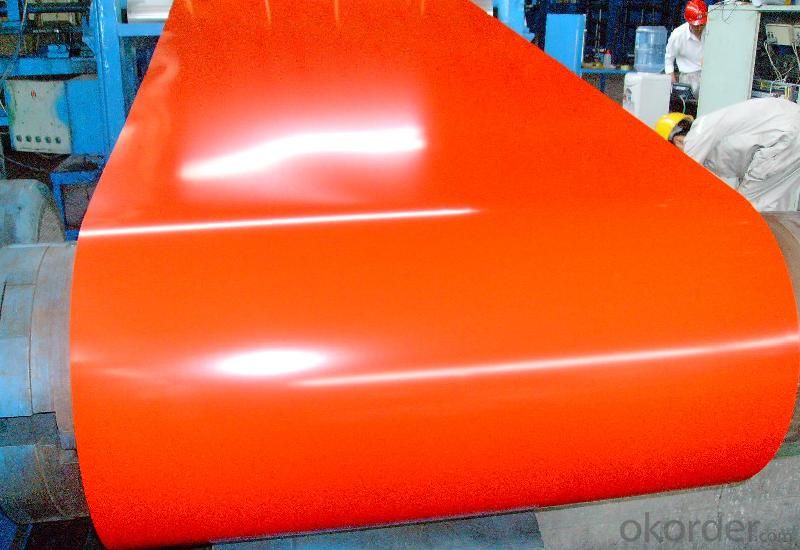

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available...

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of steel coils available?

- There exists a variety of steel coils, each possessing distinct characteristics and uses. 1. Hot Rolled Steel Coils: These coils undergo production at high temperatures and are ideal for applications requiring a sleek and polished finish, such as automotive components, construction materials, and machinery. 2. Cold Rolled Steel Coils: In order to enhance surface finish and dimensional accuracy, these coils are processed at lower temperatures. They find extensive use in industries like automotive, appliances, and electronics, where precision is of utmost importance. 3. Galvanized Steel Coils: A layer of zinc is applied to these coils to safeguard the underlying steel against corrosion. They are commonly utilized in the construction sector, roofing, and automotive parts that are exposed to harsh environmental conditions. 4. Stainless Steel Coils: Created by combining iron, chromium, and other elements, these coils offer exceptional resistance to corrosion and possess high strength. They are widely employed in applications demanding hygiene, such as food processing equipment, medical instruments, and kitchen appliances. 5. Electrical Steel Coils: Specifically designed for applications requiring magnetic properties, these coils are utilized in transformers, electric motors, and generators. They exhibit low core losses and high permeability, ensuring efficient transfer of electrical energy. 6. Pre-painted Steel Coils: These coils are coated with paint or other protective coatings to enhance their visual appeal and provide additional protection against corrosion. They are commonly used in the construction industry for cladding, roofing, and siding. 7. Tinplate Steel Coils: A thin layer of tin is applied to these coils to prevent corrosion and act as a barrier against moisture and oxygen. They find widespread usage in the packaging industry for cans, containers, and other food or beverage packaging. These examples merely scratch the surface of the various steel coil options available in the market. Each variant possesses its own unique properties and applications, rendering them suitable for diverse industries and purposes.

- Q: I'm getting new strings on my dad's old acoustic guitar so I can learn how to play it and I'm wondering if I should get nylon or steel strings. Are there any major differences between the two aside from the nylon strings being easier on your fingers? Like do the Nylon strings sound different?

- Steel strings sound much better as in brightness and tone. Nylon strings sound dull and don't hold tune well but are easier to press. You need to build calouses on your finger tips and using steel will do this, just take it easy until they form and stop when they start hurting moderately. When you put new strings on a guitar, it's very good to break them in by pulling on them from the neck upwards to stretch them out. If you don't, you will need to tune them much until they wear themselves in. Good luck and make some sweet music !!

- Q: What are the factors affecting the strength of steel coils?

- The strength of steel coils can be influenced by several factors. These include the grade of steel used, the manufacturing process employed, the thickness and width of the coils, the quality of their surface, how they are stored and handled, and the environmental conditions they are exposed to. When choosing and using steel coils, it is crucial to take these factors into account to ensure that they meet the necessary strength requirements for their intended use.

- Q: This is my first time buying new strings for my violin and I’ve narrowed it down to two choice based on reviews and cost. The only difference I can see between the strings is that one has a solid steel core and the other has a synthetic core. What are the pros and cons of each type of core?

- Play okorder /

- Q: I've been looking for lots of info on this steel. Cold Steel uses it now in their knives replacing the AUS-8 steel. I was hoping somebody had a knife with this steel who could give me some real first hand knowledge not just numbers. Thanks!

- Before I answer I must let you know that I have been a knife collector for 17 years, and have a great assortment of specialty and antique folding knives. As for your question, I wouldn't worry too much about it. The first answerer is very knowledgeable in this category. But in the real world, the steel chemistry of folding knives will never be as important as that of fixed blades or kitchen knives. The fact that manufacturures go through great lengths to advertise their superior steel is just for sales and bragging rights. When it comes down to it, a pocketknife might be useful, but it is never the best tool for the job. It is a compomised design from the beginning. If you need to cut a steak, a steak knife will do. A box cutter works best on cardboard. A razor works best for shaving, wire cutters best for cutting wire, an axe for chopping wood...I could go on. A pocket knife is never going to perform better than the real thing ( although I do prefer the can openers on Swiss army knives than real can openers). As for self defense, minus the concealability factor, a folding knife sucks compared to a fixed blade. But if you were to pull one out during an extreme circumstance, I doubt anyone is going to be effected by the Rockwell hardness.

- Q: How are steel coils used in the production of automotive exhaust systems?

- Steel coils are used in the production of automotive exhaust systems as they are shaped and formed into various components such as pipes, mufflers, and catalytic converters. These coils are cut, bent, and welded to create the necessary shapes and sizes required for efficient exhaust flow and noise reduction. Additionally, the strength and durability of steel make it an ideal material for withstanding high temperatures and harsh conditions that exhaust systems endure.

- Q: What does INOX Steel means?I have been looking up the meaning but cannot find it... please help...

- Inox Steel

- Q: What are the different methods of edge trimming steel coils?

- Manufacturers have various methods at their disposal for edge trimming steel coils, which are chosen based on their specific preferences and requirements. Some commonly used methods include: 1. Slitting: This method involves passing the coil through rotating circular blades to precisely cut the edges. It is suitable for different thicknesses of steel coils. 2. Milling: By using milling cutters, excess material is removed to achieve the desired edge finish. Milling is often employed for thicker steel coils or when a specific edge profile is needed. 3. Shearing: A sharp blade is used to cut the steel coil along a straight line, providing a clean and straight edge. This method is commonly used for thinner steel coils. 4. Laser cutting: Edge trimming is achieved by utilizing a focused laser beam to melt or vaporize the excess material, resulting in a precise and smooth edge. Laser cutting is often preferred for thinner gauges or when intricate shapes or patterns are necessary. 5. Water jet cutting: This method involves a high-pressure stream of water mixed with abrasive particles to trim the edges of the steel coil. Water jet cutting offers a versatile and precise cutting solution, particularly for thicker steel coils and complex shapes. Manufacturers should carefully assess their specific requirements, including coil thickness, desired edge finish, speed, and cost, to choose the most suitable edge trimming method for their steel coils.

- Q: Please explain why steel is denser than wood.

- Steel is basically a mixture (not the compound) of iron and carbon. Iron, by itself is an element and so is carbon. The atoms of Iron are larger in size compared to carbon. All the atoms of all the elements, smaller or larger, are spherical. If naturally a solid, the atoms of all such elements have voids as their atoms are closely packed. You can imagine a basket of oranges; you could see that void or empty space (which I am speaking about) between four or more of the oranges put together. Now, when heated to more than about 1500 degrees celcius, Iron melts and atoms in molten form increase space between themselves. Raising the teperature to 1800 degree celcius, carbon is mixed with iron. At this stage it causes the spherical carbon atoms to fill in the spaces present amongst the spherical atoms of the iron. On cooling, already dense iron becomes denser because no space is left there between its atoms. This denser form of iron + carbon has become steel in which carbon is not more than 3 to 4% of the total volume. Wood is nothing but a fallen and dried tree's part. When green and alive, tree's stem and branches have pores in there texture, which are fillled with water and other biological fluids necessary for the life of the plant. When dried all the fluids, especially water gets evaporated. and the pore are empty now. The term Density, means mass divided by volume (kg / cubic meters). Iron + Carbon (the steel) so tightly packed and Iron having very high atomic weight is surely denser than wood with just carbon and a few other elements with no significant role to play in the mass calculation; particularly if their are empty pore spaces filled with air only. Imagine the mass (which common people mistakingly call the weight) in kilograms of a peice of steel with dimensions of 1 meter cube and imagine the same for the dried wood. What do you think---which one is denser?

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

Send your message to us

Pre- painted Galvanized/ Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords