Pre-galanized EMT Conduit Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Of EMT conduit:

UL1242/ANSI C80.6 Intermediate Metal Conduit

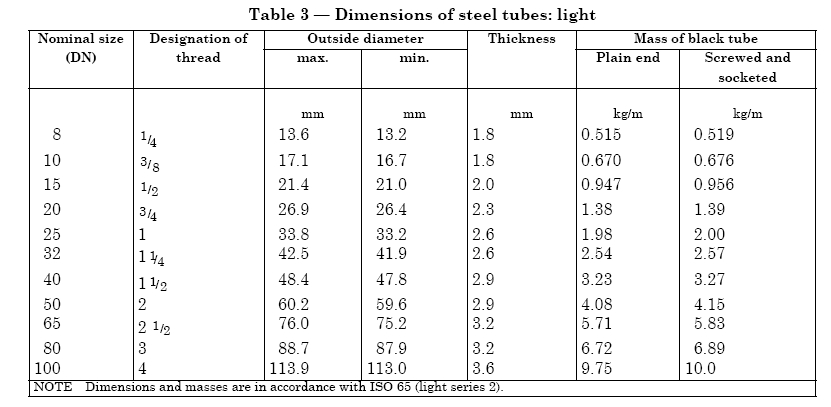

Size:

1/2"- 4".

Package:

With steel coupling & cap

Material:

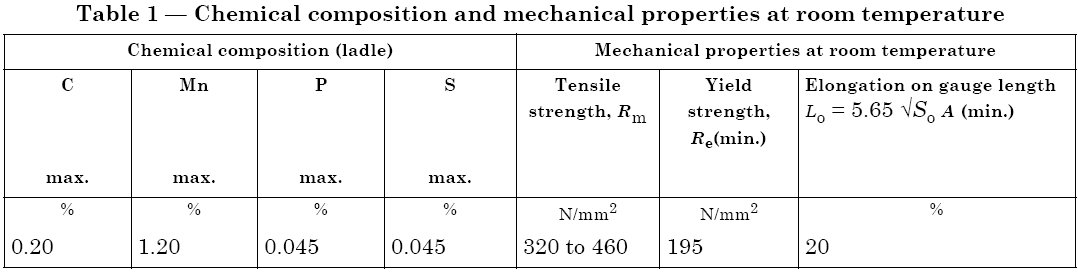

Q195 HIGH GRADE MILD STRIP STEEL

Intermediate Metal Conduit (IMC) is manufactured in accordance with:

>American National Standards for Steel. (ANSI C80.6)

>Underwriters Laboratories Standard for Electrical Metallic Tubing. (UL 1242).

Intermediate Metal Conduit (IMC) is threaded on both ends, one end is with a steel coupling, and the other end is with a plastic cap to protect the thread.

Surface:

Hot galvanized

Application of EMT conduit:

1 For low pressure liquid delivery such as water, gas and oil

2 For construction, e.g building greenhouse

Delivery of EMT conduit:30-50days

- Q: Can steel pipes be used for stadium construction?

- Yes, steel pipes can be used for stadium construction. Steel pipes offer several advantages that make them suitable for this purpose. Firstly, steel pipes are strong and durable, making them capable of withstanding heavy loads and providing structural stability to large structures like stadiums. They have high tensile strength, which means they can resist bending or breaking under pressure. Additionally, steel pipes are resistant to corrosion, which is crucial for outdoor structures like stadiums that are exposed to various weather conditions. Their resistance to rust and other forms of degradation ensures the longevity of the stadium. Furthermore, steel pipes are versatile and can be easily fabricated into different shapes and sizes, allowing for customized designs and efficient installation. Moreover, steel pipes offer cost-effectiveness in stadium construction. They can be easily produced in large quantities, making them readily available and affordable. The ease of transportation and installation of steel pipes also contributes to their cost-effectiveness. Another advantage of using steel pipes for stadium construction is their sustainability. Steel is a recyclable material, and using steel pipes promotes environmental responsibility. The recyclability of steel reduces the demand for new materials and minimizes waste. In summary, steel pipes can indeed be used for stadium construction due to their strength, durability, resistance to corrosion, versatility, cost-effectiveness, and sustainability.

- Q: How are steel pipes used in airport infrastructure?

- Steel pipes are commonly used in airport infrastructure for various purposes. They are used in the construction of runways, taxiways, and aprons to provide a strong and durable foundation. Steel pipes are also used for drainage systems, fuel pipelines, and fire suppression systems within the airport premises. Additionally, steel pipes are used in the construction of airport buildings, such as hangars and terminals, for structural support and plumbing systems. Overall, steel pipes play a crucial role in ensuring the safety, efficiency, and functionality of airport infrastructure.

- Q: How are steel pipes used in the construction of high-rise buildings?

- Steel pipes are commonly used in the construction of high-rise buildings for various purposes. They are primarily used as structural elements, forming the framework and supporting the weight of the building. Steel pipes provide strength and durability, making them suitable for withstanding the vertical and lateral loads experienced by tall buildings. Additionally, steel pipes are used for plumbing and electrical systems, as well as for heating, ventilation, and air conditioning (HVAC) installations. Their versatility, reliability, and ease of installation make steel pipes an essential component in the construction of high-rise buildings.

- Q: Can steel pipes be used for underground sprinkler systems?

- Yes, steel pipes can be used for underground sprinkler systems. Steel pipes are known for their durability and strength, making them a suitable choice for underground applications. They are resistant to corrosion and can withstand high pressure and temperature, making them suitable for delivering water to sprinkler heads. However, it is important to note that steel pipes may require additional coatings or protective measures to prevent rusting and corrosion over time. Additionally, steel pipes may be more expensive than other materials such as PVC or polyethylene, so the cost factor should be considered as well. Overall, steel pipes can be a viable option for underground sprinkler systems, particularly in areas with harsher environmental conditions.

- Q: Are steel pipes suitable for offshore drilling platforms?

- Steel pipes have been widely used in offshore drilling platforms because of their strength, durability, and resistance to corrosion. These platforms operate in harsh marine environments, where they are exposed to saltwater, extreme pressure, and temperature changes. Steel pipes are capable of enduring these conditions and serving as a reliable and long-lasting solution for transporting fluids, such as oil and gas, from the seabed to the surface. Moreover, the ability to weld steel pipes together facilitates their easy installation and maintenance on offshore drilling platforms. In conclusion, steel pipes have proven to be an appropriate choice for offshore drilling platforms due to their robustness and ability to withstand the challenging conditions of the marine environment.

- Q: Are steel pipes suitable for wastewater pumping stations?

- Yes, steel pipes are suitable for wastewater pumping stations. Steel pipes are known for their durability and strength, making them an excellent choice for handling the harsh conditions and high-pressure requirements of wastewater pumping stations. They have the ability to withstand the corrosive nature of wastewater and can resist damage caused by chemicals and other aggressive substances commonly found in wastewater. Additionally, steel pipes are available in various sizes and thicknesses, allowing for customization to meet the specific needs of the pumping station. Furthermore, steel pipes can be easily welded and joined together, ensuring a secure and leak-free system. Overall, steel pipes offer a reliable and long-lasting solution for wastewater pumping stations.

- Q: What is the typical diameter range of steel pipes?

- The typical diameter range of steel pipes can vary depending on various factors such as the intended application, industry standards, and specific project requirements. However, in general, steel pipes are available in a wide range of diameters to suit different purposes. Commonly used diameters for steel pipes can range from small diameters of around 0.5 inches (12.7 mm) to larger diameters of several feet or more. This range allows for various applications such as plumbing, oil and gas transportation, structural support, and industrial processes. Ultimately, the specific diameter of a steel pipe will be determined by the specific needs of the project or application at hand.

- Q: What is a steel pipe?

- A steel pipe is a cylindrical hollow tube made from steel material, commonly used in various industries for transporting fluids, gases, or solids, as well as for structural applications.

- Q: How are steel pipes used in the construction of underground parking garages?

- Steel pipes are used in the construction of underground parking garages for various purposes, including providing structural support, serving as conduits for utilities such as water and electricity, and facilitating drainage systems. They are often used as deep foundation elements to support the weight of the structure and the vehicles above. Additionally, steel pipes are commonly used for installing fire suppression systems, ventilation systems, and plumbing connections within the parking garage.

- Q: Welded and seamless steel pipe how to distinguish?

- Generally, careful observation, can see traces of the weld seam pipe, further is the determination of the polished incision, and then with the file can be seen there is no clear cut, interface traces with the file cleanup to remove when cutting was pasted interface.

1. Manufacturer Overview

| Location | Tianjin ,China |

| Year Established | 2004 |

| Annual Output Value | Above 100milion rmb |

| Main Markets | Main land;Middle East;Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | 38000squar meter |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Pre-galanized EMT Conduit Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords