PPGI,Pre-Painted Steel Coil High Quality Green Color

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

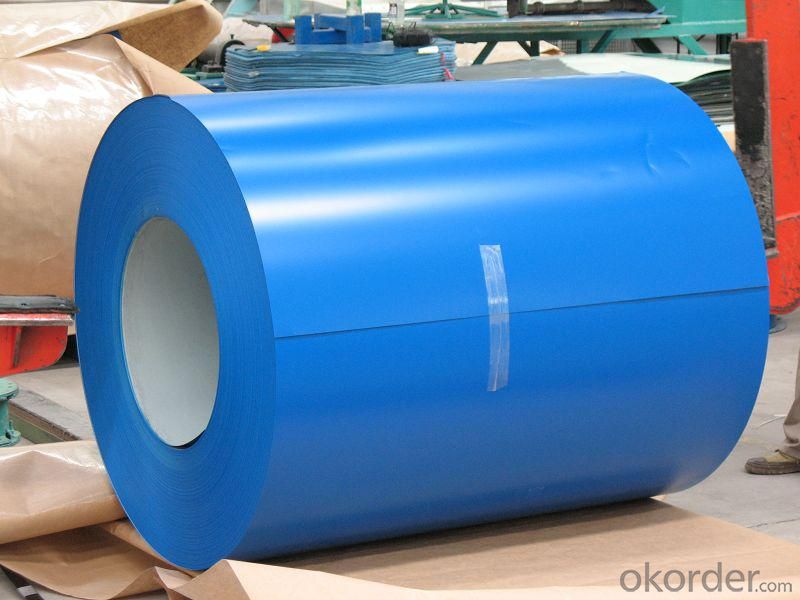

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

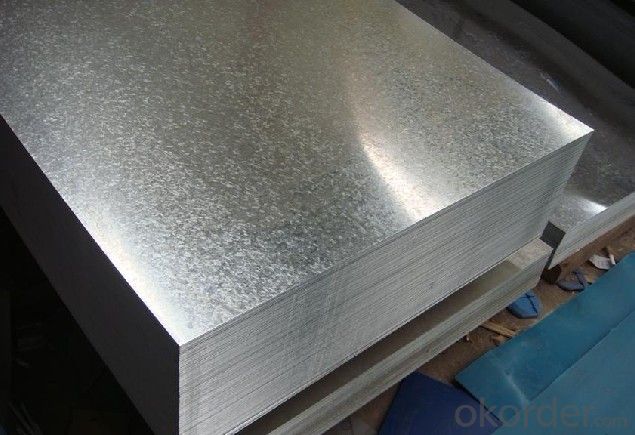

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images:

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

Roof, roof structure, surface sheet of balcony, frame of window, etc.

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of telecommunications equipment?

- Steel coils are used in the manufacturing of telecommunications equipment as they are commonly used as a raw material for various components, such as enclosures, cabinets, and brackets. The coils are processed and shaped to create the necessary parts that provide structural support, protection, and stability to the telecommunications equipment.

- Q: Can you recycle steel? And if you wanted to buy some recycled steel, where would you get it?

- Yes; steel can be recycled. Look on the Internet for dealers who sale recycled steel. Good luck! Smile!

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: Is steel with a black coloring as strong as regular steel. if you are asking why i have two wordsBlack Katana.I know a katana is not made with normal steel, it is made of two types with varying grades of carbon to give it speacial properties, i just want to know if the black will make a difference.

- There are many types of steel some very rigid, while you can have steel that is very flexible. The type of katana: steel is for Samurai swords

- Q: My boyfriend is a loyal follower of this guy called Dr. Steel.

- Dr. Steel is an extremely complex phenomenon, a bit of a metaphorical nesting doll. On the surface, Dr. Steel can appear to some as simply a method actor musician with an over-the-top gimmick. Just underneath that facade lies an enigma; he makes some people wonder if he's really serious, just trying to entertain, or completely barking mad. But underneath the second facade, Dr. Steel is really acclaimed comic-book writer and chaos magickian, Grant Morrison. Make no mistake, he really thinks he is Dr. Steel. He has taken method acting and ceremonial magick to the highest levels, and fully intends to take over (or make over) the world. What's more, in the three short years since handing over his comic-book authorship to a ghost writer, he has amassed tens of thousands of followers worldwide. I've done several polls among Dr. Steel fans, and the results show that for every one person who has officially signed up, there are ten more loyal followers who have not.

- Q: What are the common coil surface treatments?

- Some common coil surface treatments include galvanizing, painting, and powder coating. These treatments help protect the coil from corrosion, improve its appearance, and increase its durability.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

- Q: How are steel coils used in the manufacturing of braking systems?

- Steel coils are used in the manufacturing of braking systems as they are commonly used to make brake pads and brake rotors. Steel coils are processed and shaped into the required forms to create these essential components, which play a crucial role in the braking system's functionality and performance.

- Q: What are the common storage defects in steel coils?

- Some common storage defects in steel coils include: 1. Staining or discoloration: If steel coils are not stored properly, they can be exposed to moisture or chemicals, leading to staining or discoloration. This can affect the appearance and quality of the steel. 2. Rust or corrosion: Steel is susceptible to rust and corrosion if it comes into contact with moisture or is stored in a humid environment. Rust can weaken the steel and compromise its integrity. 3. Coil deformation: Improper stacking or handling of steel coils can result in deformation or bending. This can occur when coils are stored on an uneven surface or subjected to excessive pressure or weight. 4. Surface damage: Steel coils can develop surface scratches, dents, or abrasions if they are mishandled during storage. This can be caused by improper stacking, handling, or transport of the coils. 5. Edge damage: If steel coils are not properly protected or secured during storage, the edges can become damaged. This can include chipping, cracking, or bending of the edges. Edge damage can affect the usability and safety of the steel coils. 6. Coil slippage: When steel coils are not securely stored or stacked, they can slip or roll off, causing damage to the coils themselves and potentially causing harm to nearby personnel or equipment. 7. Contamination: Steel coils can become contaminated if they are stored near or come into contact with substances such as dirt, oil, grease, or chemicals. Contaminants can affect the quality and performance of the steel. 8. Coil nesting: Inadequate spacing or stacking of steel coils can result in coil nesting, where one coil becomes embedded or nested within another. This can lead to damage to the coils, making them difficult to separate and use. To prevent these common storage defects, proper handling, storage, and protection measures should be implemented. This includes storing steel coils in a dry, well-ventilated area away from moisture and chemicals, using appropriate stacking and support structures, and providing adequate protection against impacts and contaminants. Regular inspections and maintenance should also be conducted to identify and address any potential defects or issues.

- Q: Obviously this is an easy question for anyone who works with metal. However, I am currently writing a book and had an idea that had to do with these two metals. Is it possible for gold to be folded into steel while it is being forged? Do 3-metal alloys exist? If this is not possible with current metal-working techniques and technology, what would be needed to make it possible? And finally, what exactly would the mixing of these two yield? A weak metal? A brittle metal? How would it compare to iron or gunmetal? If you have no idea, please offer speculations. Thank you!

- Since steel is already an alloy (iron with other metals or carbon), you're not alloying gold with a a metal per se. It is possible, though, to alloy gold with steel. However, the creation of any alloy has a practical application behind it. For example, gold is alloyed with silver and copper because otherwise, the gold is too soft to stand up to the use it is intended for and needs to be hardened.

Send your message to us

PPGI,Pre-Painted Steel Coil High Quality Green Color

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords