PPGI / Color Painted Galvalume Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PPGI / Color Painted Galvalume Steel Coils description:

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets. The structure of prepainted steel includes finished coating, primer coating, chemical conversion coating metallic coating and cold-rolled steel. The prepainted steel sheets are mainly provided for various commercial purposes covering architectural construction, electrical household appliances, transportation, etc

Specification :

Base metal | Hot dipped galvalume steel |

Thickness | 0.15mm-1.2mm |

Width | 700mm-1250mm |

Coil ID | 508mm / 610mm |

Layers of the coating | 2/2(2 layers of top coating/2 layers of bottom coating); 2/1(2 layers of the top coating, 1 layer of bottom coating); 1/1(single layer of top coating/ single layer) |

Color | According to customers’ request |

Paint

| PE / PVDF |

Thickness of the coating | 15um-25um |

AZ coated | 50g/m2-275g/m2 |

Surface | Film coverd |

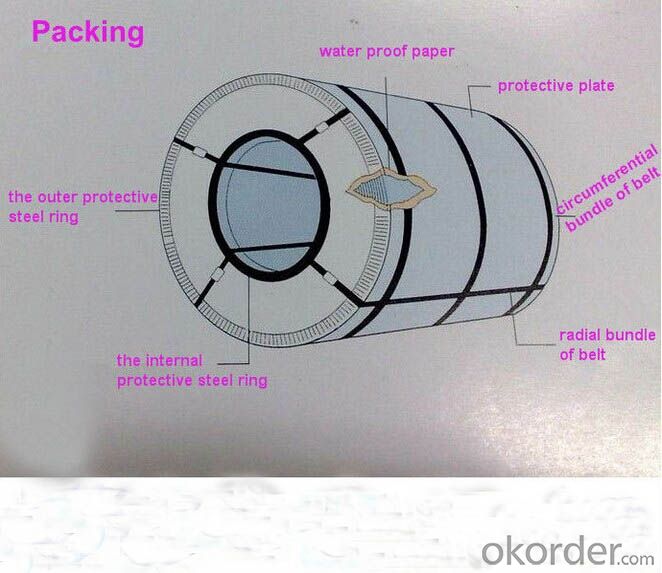

Package | Waterproof paper + polyethylene rush inhibitor,the antirust paper , the ring of defendse on inside and outside, steel belt, and the guard plate.

We can also pack according to your request details. |

Applications:

construction | workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door |

door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter | |

Electrical appliance | refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker |

Furniture | central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf |

Carrying trade | exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board |

other | writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment |

- Q: what is the difference between METAL and STEEL?

- Most sheet metal is coated with galvanizing. Not fun to weld on. Most steel for welding use is just carbon steel.

- Q: I'm currently in an Estimating and Bidding class. I have to estimate two divisions for a multi-million dollar project. The project that I chose is around 6 million dollars and involves constructing a new gas/lighting building. I chose to estimate steel, and my question is, around how much out of the 6 million goes toward just the steel estimate? If it helps, this building is has two floors and is roughly about 100x70 feet. The building not wood construction, but rather steel and brick. How much of that 6 million would go into the steel? I'm not looking for anything exact, just roughly.

- That is a little tough to answer given the details. I will try to answer it as best I can. You can send me a message if you need further help and I can get some more details from you. If it is a 6 million dollar project, that is about $428/sf - (6 million divided by 14,000 sf). $428 is a little bit higher end then say, just a Walmart which is a block and steel box. Assuming you have a concrete slab on the first floor, metal deck on the second floor, with steel beams and open web joists framing, steel columns and steel roof framing with a metal deck roof.... you could be approx 10-15% of the total 6 million. Now, this would include the structural steel, not light gauge steel framing for walls. It sounds like you are looking for structural steel, not metal stud framing. Hopefully this helps, I can check back to this thread later to see if you've had to add any more details.

- Q: What we have to keep in mind before buying a steel building?

- Here is a web search of the term steel building specification. It should give you some ideas and sources.

- Q: What are the common manufacturing defects in steel coils?

- Common manufacturing defects in steel coils include surface defects such as scratches, pits, and dents, as well as internal defects like inclusions, cracks, and voids. Other common defects can include uneven thickness, waviness, and coil set.

- Q: How are steel coils used in the petrochemical industry?

- Steel coils are commonly used in the petrochemical industry for various purposes such as manufacturing pipes, tanks, and equipment used in the processing and transportation of petrochemical products. The coils are typically formed into specific shapes and sizes to meet the industry's requirements, ensuring structural integrity and resistance to corrosion. These steel components play a critical role in maintaining the safety and efficiency of petrochemical operations.

- Q: What are the characteristics of hot-rolled steel coils and cold rolled steel coils? What loading and unloading tools should be used? What items should be paid attention to?

- When placing materials to roll on both sides of the main pad wood pallets, prevent rolling back and forth. In addition the floor should be thickened, cannot have uneven or debris, because the line of steel coils when gravity concentrated in contact with the ground floor, there is a fracture easily, debris, easy to leave the indentation in the steel roll.

- Q: I do a lot of scrapping and would like to be able to separate stainless steel from regular steel. The magnet test doesn't always work since stainless can be magnetic, but what are some ways that I can for sure tell the difference? Or even something like a sound that they make that may help me to tell the difference.

- Stainless steel should be non-magnetic.

- Q: How are steel coils used in the manufacturing of wires?

- Steel coils are used in the manufacturing of wires by being fed into wire drawing machines, where they are gradually reduced in diameter through a series of dies. The steel coils serve as the initial raw material, providing the necessary strength and flexibility for the wires to be produced.

- Q: How do steel coils contribute to the water and wastewater industry?

- Steel coils contribute to the water and wastewater industry by being used in the construction of pipes, tanks, and other infrastructure. These coils provide strength, durability, and corrosion resistance, ensuring the integrity and longevity of water and wastewater systems. Additionally, steel coils are often utilized in the manufacturing of water treatment equipment and machinery, helping to improve the efficiency and effectiveness of the water and wastewater treatment processes.

- Q: How are steel coils used in the production of lighting fixtures?

- Steel coils are an essential component in the production of lighting fixtures. These coils are typically made of high-quality steel, which provides durability and strength to the final product. In the manufacturing process, the steel coils are first uncoiled and then passed through a series of machines. These machines cut and shape the steel into various parts and components required for lighting fixtures. The steel is often bent, stamped, or rolled to create the desired shapes and sizes. These parts may include the base, frame, arms, or other structural elements of the lighting fixture. Once the steel components are formed, they are then further processed and finished. This may involve welding, polishing, or coating the steel to enhance its appearance and protect it from corrosion. After the steel parts are finalized, they are assembled with other components like electrical wiring, bulbs, shades, and switches to create the complete lighting fixture. The use of steel coils in lighting fixture production ensures that the finished products are sturdy, long-lasting, and able to withstand various environmental conditions. Steel's strength allows for the creation of intricate designs and shapes, enabling manufacturers to produce lighting fixtures that are not only functional but also aesthetically pleasing. Overall, steel coils play a crucial role in the production of lighting fixtures by providing the necessary strength, durability, and versatility required for these products.

Send your message to us

PPGI / Color Painted Galvalume Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords