PPGI/Best Price Prepainted Galvanized Steel Coil with Zinc Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Best Price Prepainted Galvanized Steel Coil with Zinc Coating

1. Detailed Specifications:

| Product | Best Price Prepainted Galvanized Steel Coil with Zinc Coating |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application:

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

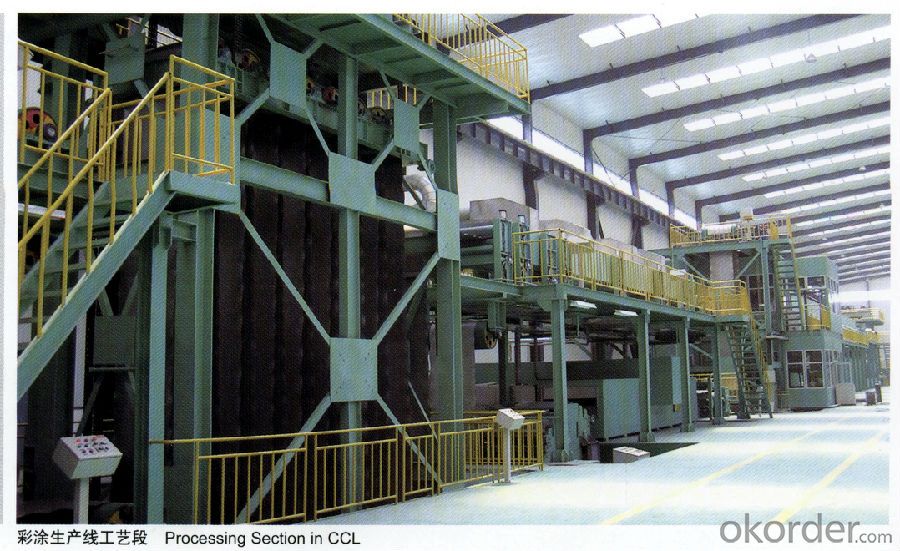

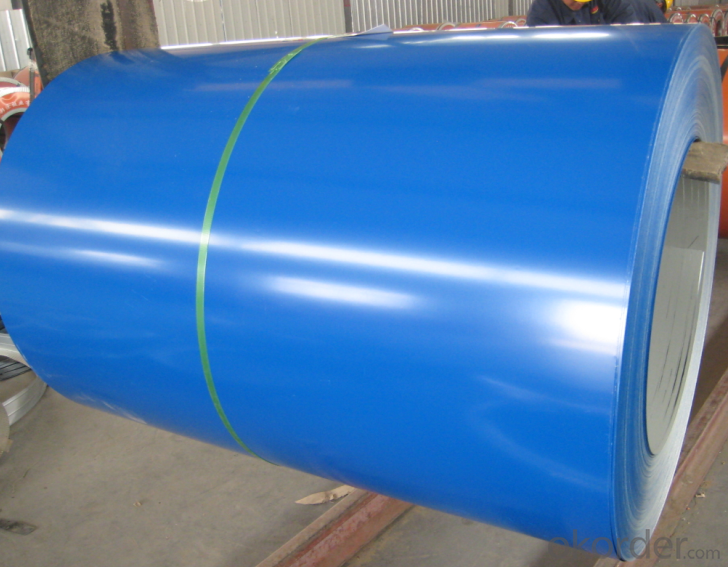

3. Image:

production Line:

production show:

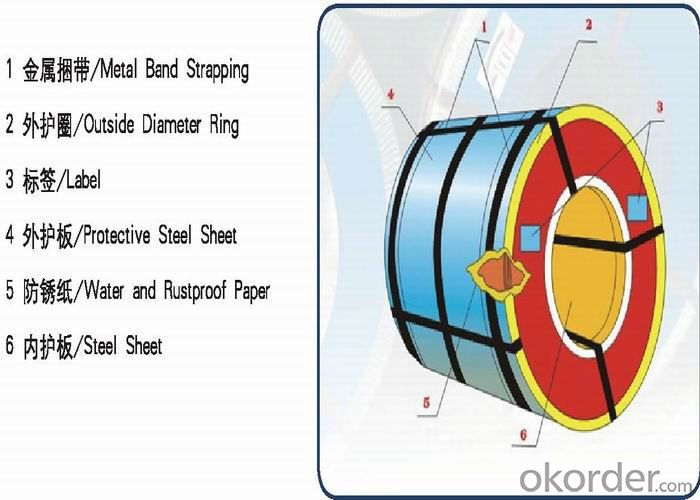

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5. RFQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1Year for the whole light. Warranty is based on correct storage, installation, using and mainten anc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as so on as possible.

- Q: What is the AISI grade of mild steel that is the most magnetic? What magnetic steels are the cheapest and easiest to buy?

- From what I understand, the best material for cores is not the most magnetic but the rather the one having less loss due to hysteresis,

- Q: looking to buy a sashimi knife. what is the difference between white steel (1and2) and blue steel (1and2) in terms on characteristics. what gets sharper? what holds edge longer? basically any info on the pros and cons of each steel would be SO GREATLY APPRECIATED! thanks in advance to all who answer. i'm leaning towards white-2 steel for my first sashimi knife, started training on the sushi bar and need a new tool!

- Blue Steel Knife

- Q: Is steel framing eco friendly? Why or why not.

- Most of it is made from recycled iron and steel. You can also climb a ladder carrying a dozen steel studs far easier than you can lumber studs. It is this latter part why it is so popular in some areas.

- Q: How are steel coils processed for heat treatment?

- Steel coils are processed for heat treatment by first being cleaned and prepped for the treatment. They are then heated to a specific temperature and held at that temperature for a set period of time to achieve desired properties such as improved hardness or ductility. After heat treatment, the coils are slowly cooled down to room temperature to prevent any distortion or cracking.

- Q: How are steel coils used in the manufacturing of safety systems?

- Steel coils are commonly used in the manufacturing of safety systems such as airbags and seat belts. The steel coils are formed into springs which provide the necessary tension and force to ensure the proper functioning of these safety devices. The coils are carefully designed and integrated into the system to enhance its performance and reliability, ultimately helping to protect occupants in the event of a collision.

- Q: What are the different surface finishes of steel coils?

- There are several different surface finishes of steel coils, including mill finish, galvanized finish, painted finish, and coated finish.

- Q: What are the commonly used molds steel?

- Usually a hot working grade ( H series ) tool steel is used in die cast mold detail tooling. We typically use H-13 for our applications but have substituted with D-2 on occasion.

- Q: I found the cold steel kukri machete online and I am very impressed and am thinking of ordering it. A friend of mine said that the cold steel kukri machete is nothing compared to the KaBar Kukri Machete. I was wondering if other people who own these machetes could tell me the good and the bad of each machete. Such as what they have been able to cut. If they break easily and such. Thanks in advance.

- cold steel will be thin but made of a carbon steel good enough but not perfect flexable and as for cutting power that varies piece to piece as not all places sell sharpened models so be prepared to hand sharpen in any case you would need to hand sharpen sooner or later so a sharpening stone is a good investment no matter what machete you buycold steel is fine for most peoples need for them unless you see a better price go with either one

- Q: What are the trends and developments in the steel coil industry?

- The steel coil industry has witnessed several trends and developments in recent years. These changes have been driven by various factors, including technological advancements, shifts in demand and supply dynamics, and environmental concerns. One significant trend in the steel coil industry is the increasing use of advanced technologies in production processes. Automation and robotics have revolutionized steel coil manufacturing, leading to improved efficiency and quality control. These technologies have also enabled the industry to meet the growing demand for customized steel coils, as they allow for faster and more precise production. Another trend in the industry is the shift towards lightweight and high-strength steel coils. With the rising need for fuel-efficient vehicles, manufacturers are looking for lighter materials that maintain strength and durability. Steel coil producers are developing innovative products that meet these requirements, such as advanced high-strength steels and ultra-high-strength steels. These materials offer improved performance while reducing the weight of the final product. Environmental concerns have also spurred developments in the steel coil industry. There is a growing demand for sustainable and eco-friendly steel coils, which has led to the adoption of greener manufacturing processes. Steel coil manufacturers are increasingly utilizing recycled materials and implementing energy-efficient technologies to reduce carbon emissions and waste generation. Additionally, there is a focus on improving the recyclability of steel coils to minimize the environmental impact throughout their lifecycle. Furthermore, the steel coil industry is witnessing a shift in demand and supply dynamics. Emerging economies, particularly in Asia, are driving the demand for steel coils due to rapid industrialization and urbanization. This has led to increased investments in production capacity in these regions. On the other hand, developed economies are experiencing a trend towards consolidation and specialization, with some companies focusing on niche markets or specific steel coil applications. Overall, the steel coil industry is undergoing significant transformations driven by technological advancements, changing demand patterns, and environmental concerns. These trends and developments are shaping the landscape of the industry, making it more efficient, sustainable, and adaptable to evolving market needs.

- Q: What is the role of steel coils in the electrical industry?

- The electrical industry greatly relies on steel coils due to their versatile applications and significant contributions. Transformers, which play a crucial role in power distribution and voltage regulation, utilize steel coils as essential components. These coils facilitate the transfer of electrical energy between circuits, enabling efficient transmission over long distances. Moreover, electric motors and generators heavily rely on steel coils. These coils are wound around the stator and rotor, creating magnetic fields that facilitate the conversion of electrical energy into mechanical energy and vice versa. This conversion process holds immense importance in industries such as automotive, manufacturing, and renewable energy. Steel coils also serve a vital purpose in the production of electrical cables and wiring. They provide strength, durability, and protection to the conductive copper or aluminum wires within the cables, ensuring their structural integrity. This, in turn, guarantees safe and efficient electricity transmission. Additionally, steel coils find application in electrical equipment like solenoids and relays. Their presence enables the creation of magnetic fields that control the flow of electrical current. Furthermore, various electrical appliances, including refrigerators, air conditioners, and televisions, rely on steel coils as crucial components for their proper functioning. In conclusion, the role of steel coils in the electrical industry cannot be overstated. From transformers to motors, generators, cables, and electrical equipment, these coils contribute significantly to the efficient distribution, conversion, and transmission of electrical energy.

Send your message to us

PPGI/Best Price Prepainted Galvanized Steel Coil with Zinc Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords