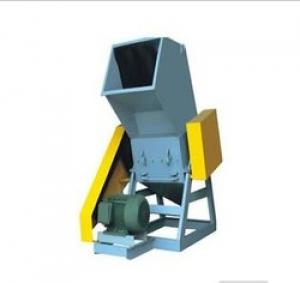

Plastic Recycling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets Per Month set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Details: | Standard exported packing |

|---|---|

| Delivery Detail: | 30 days after receiving deposit |

Specifications

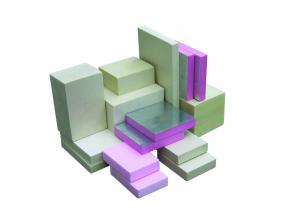

PP Plastic recycling machine

1).Recycling PE film or PP woven bags.

2).Capacity 350kg/h.

3).Structure & quality improved

Detailed Product Description:

Product Name: YZJ180 PS Foam Recycling Machine

Product Code: YZJ180

Technical Parameter:

| Model | Motor Power | Shredding Chamber Dimension | Weight |

| SS-600 | 11kw | 550mm*600mm | 2900kg |

| SS-600 | 15kw | 550mm*600mm | 3000kg |

| SS-800 | 15kw*2sets-22kw*2sets | 600mm*800mm | 4200kg |

| SS-1000 | 22kw*2sets-45kw*2sets | 600mm*1000mm | 6800kg |

| SS-1200 | 30kw*2sets-55kw*2sets | 800mm*1200mm | 7500kg |

| SS-1400 | 30kw*2sets-75kw*2sets | 1000mm*1400mm | 10000kg |

- Q: How do you make a tower out of old plastic bottles?

- We only do 'bottle to bottle', we're going to make the food grade PET chips out of the old bottles, and then produce new bottles. After the bottle is used up, we slice it, so the resources can be recycled many times. Yao Yaxiong gestured introduction. Guo Xin also said she was reluctant to use recycled materials as clothes, because the waste bottles were simply broken, and they could not be recycled when they were made of short fiber or woven bags. International certification market open based company clean and spacious courtyard, neatly with a row of nearly 4 meters high packed waste bottle. Dirty plastic bottles come here, and after a process, they become transparent slices, or crystals, which can be used directly to produce plastic bottles we often see. And this kind of closed loop method has become a typical model of recycling economy and renewable resources industry. Yao Yaxiong said that different countries adopt the surplus production line mainly equipment from Europe, forming a complete set of production line through its integrated innovation. Now, with the surplus production line is the only Asian one, is now a recovery of the world largest single line capacity by production line waste polyester bottle. While a surplus products not only fully meet our requirement, and also made the United States Food and Drug Administration (FDA) and ILSI (International Life Science Institute) standard certification, become the only one with the production capacity of enterprises China. Now, itmake began the domestic development in the equipment, the future not only itself is a surplus of renewable plastic production enterprises, can also become a technology, equipment management and other similar enterprises of the provider. After solving the recycling system of "regular army" difficult market access issues, cost recovery system has made such a surplus "regular army" headache.

- Q: How to use the beverage bottle recycling machine?

- Plastic bottles are made of polyethylene or polypropylene and added a variety of organic solvents. Plastic bottles are widely used polyester (PET), polyethylene (PE) and polypropylene (PP) as raw materials, after adding the corresponding organic solvents,

- Q: It's a package of cookies, crisps, and the like

- Food wastePlastic can not be recycled; paper can be recycled

- Q: Hello, my name is Li Quan. I live in Tonghai County of Yuxi city. I want to make plastic recycling granule at home. Which brand of machine is easy to use? Thank you

- Mainly depends on your other people's investment budget, machinery and equipment budget to determine what kind of equipment you use. I have worked in machinery factory for over 10 years, and I have more opportunities to communicate with each other.

- Q: Ready to invest in plastic recycling industry, because the funds are not very adequate, I would like to know how much to buy a waste plastic granulator?

- Waste plastics recycling machine, different models, prices are also very different, productivity is also a world of difference, in order to study the National Plastics Machinery news, there are 30kg/h, there are 300kg/h, it depends on your needs. The price is about 20 thousand -49 10000, I hope I can help you

- Q: Waste plastic bottle machine was acquired after breaking it

- Look what is the bottle, the general coke bottle is PET, will be more expensive, other mineral water bottles will be cheaper, probably the acquisition of the former, the price of 3500, and the latter 2500 or so

- Q: Are there any machines for recycling waste plastic bags in domestic waste?

- Sorting devices are available, but they are imported equipment.

- Q: How can the old plastic bottles be recycled?

- Usually, after drinking the drink, we throw the bottle and throw it into the garbage bin. We seldom care about the fate of it. If we can recycle and reuse the bottles that we have lost, it will actually produce a new oil field." Beijing renewable resources board limited company general manager Yao Yaxiong introduction, "every recycling 1 tons of waste plastic bottles, saving 6 tons of oil. Recycling plastic bottles can itmake per year 50 thousand tons, equivalent to annual savings of 300 thousand tons of oil."The last century since 90s, the international resources recycling technology and recycled plastics industry developed rapidly, many multinational companies have begun to use recycled polyester raw materials in a certain proportion in its products (i.e. waste plastic bottles): for example, Coca-Cola plans to 2011, so that all the coke bottle regeneration composition ratio reached 25%; by 100% British retailer Tesco recycled materials packaging beverage on the part of the market; recycled polyester introduced in 2008 25% in the French Evian mineral water bottle in...... Bottle grade PET chip Yingchuang company has Coca Cola Co to supply the coke bottle every 10 years there is a surplus from. The French food group Danone, Adidas and other international companies is also in talks with a surplus purchasing.

- Q: Automatic scraps recycling machine is what how to use?

- So I closed plastic garbage collection machine by using direct injection of its new product when material re used currently to make Ji machinery push full self closing machine material

- Q: What kind of equipment should be used to recycle waste plastics such as bronzing film?

- Bronzing film, the most important thing is to rub. That's easy to fall off. Difficult is the aluminized film, need to use NAOH with high temperature..

We devoted to the designing & production of extrusion blow molding machine, pp strap production line, coating machine and with total investment 500 million RMB, covering a total area of 70,000 M2.And we aim to be one of the best and strongest plastic machinery and plastic products in the world. The marketing network has covered all over the world.

1. Manufacturer Overview

| Location | Sichuan,China (Mainland) |

| Year Established | 2002 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South America2 % Eastern Europe 2 % Southeast Asia 1.5% Africa 1 % Mid East2.5 % Eastern Asia 2 % Central America 1% South Asia 1 % Domestic Market 87 % |

| Company Certifications | CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Average |

Send your message to us

Plastic Recycling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets Per Month set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords