PVC Board Foam Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 4 Sets Per Quarter set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

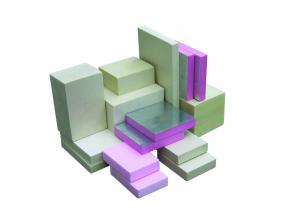

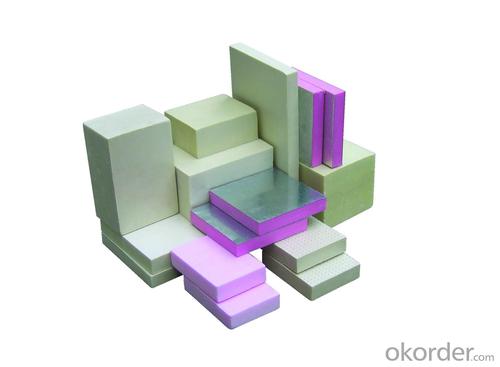

Specifications of PVC Board Foam Machine

chemical stability

corrosion resistance

hardness

high strength, anti-ultraviolet

PVC board foam machine:

Board width:1000-1500mm

Board thickness:2-20mm

Application of PVC Board Foam Machine:

Color:Light gray, dark gray, gray and other colors to customer requirements.

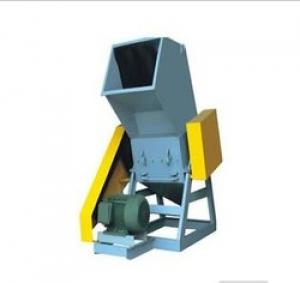

Packaging & Delivery of PVC Board Foam Machine

Packaging Details: surface wrapped with film, packed in wooden case for shipment

Delivery Detail: 65 working days

- Q: What kind of machine is needed for a small plastic bottle recycling plant to be put into operation first?.

- Can make a bottle of brick (with hydraulic baler), do the broken pieces (stripping machine, crusher), do a good PET, on the basis of the front and then need cleaning machine, dehydration machine.

- Q: not knowing what would be feasible or what kind of machinery to buy! FiftyDo a simple understanding of, want to study, development, or more professional to point to valuable advice ha!

- This industry can, a water tank, granulator, crusher, must have high voltage, on the basic of these things.

- Q: Waste plastics recycling machinery market prospects, consult the people to answer

- The prospects are good. The industry is concerned with protecting the environment. I believe the government will support it in the future

- Q: How do you make a tower out of old plastic bottles?

- We only do 'bottle to bottle', we're going to make the food grade PET chips out of the old bottles, and then produce new bottles. After the bottle is used up, we slice it, so the resources can be recycled many times. Yao Yaxiong gestured introduction. Guo Xin also said she was reluctant to use recycled materials as clothes, because the waste bottles were simply broken, and they could not be recycled when they were made of short fiber or woven bags. International certification market open based company clean and spacious courtyard, neatly with a row of nearly 4 meters high packed waste bottle. Dirty plastic bottles come here, and after a process, they become transparent slices, or crystals, which can be used directly to produce plastic bottles we often see. And this kind of closed loop method has become a typical model of recycling economy and renewable resources industry. Yao Yaxiong said that different countries adopt the surplus production line mainly equipment from Europe, forming a complete set of production line through its integrated innovation. Now, with the surplus production line is the only Asian one, is now a recovery of the world largest single line capacity by production line waste polyester bottle. While a surplus products not only fully meet our requirement, and also made the United States Food and Drug Administration (FDA) and ILSI (International Life Science Institute) standard certification, become the only one with the production capacity of enterprises China. Now, itmake began the domestic development in the equipment, the future not only itself is a surplus of renewable plastic production enterprises, can also become a technology, equipment management and other similar enterprises of the provider. After solving the recycling system of "regular army" difficult market access issues, cost recovery system has made such a surplus "regular army" headache.

- Q: Where can I get recycled plastic particles? 20Xingtai also around the line, want to do waste plastics processing into particles.Do you need a lot of water to process this? Can it pollute?

- Ziyang Sichuan Dayun plastic machinery factory specializing in the production of plastic granulatorGranulator is a complete granulator composed of extruder and corresponding granulation auxiliary machine. Mainly used in the production of PP, PE, ABS and other plastic pellets, the production of plastic particles even, dense, beautiful. PVC/PE/PS series granulator has the advantages of good plasticizing effect, high production efficiency, compact whole machine structure and high automation. The whole production line for a high degree of automation, automatic assembly line, as long as the front to pick someone behind the waste plastics, granular product line, from the implementation of the waste plastic particles to directly change the product; the whole production line based on foreign equipment drawing, continuous improvement, reasonable design, beautiful appearance. Durable, make particles of high quality, no bubbles, plump; in the field of plastic granulation equipment, adhere to professional management, practicing professional integrity, dedicated service service concept, is committed to creating Chinese professional recycled plastics recycling granulation machinery first brand - Dayun plastic machine manufacturing machine of fine quality competitive advantage for you.

- Q: It's a package of cookies, crisps, and the like

- It belongs to plastic garbage and can be recycled.Food packaging bags should be made of food grade plastic film, usually composite bags of more than two layers.Utilization of waste plasticsRecycled materialThe recycling and reuse of waste plastics has been widely adopted by modern chemical enterprises. Waste plastics after artificial screening classification, but also through crushing, granulation, modification process, into a variety of transparent opaque plastic particles, again according to the product classification, finally it can be recycled again by the.FuelIn the beginning, plastic recycling was largely done by burying or incinerating, which resulted in great waste of resources. Therefore, foreign waste plastics are used for blast furnace injection instead of coal, oil and coke. It is used for cement rotary kiln instead of coal, firing cement, and making solid waste fuel (RDF) for power generation, the effect is ideal.

- Q: What are the waste recycling app?

- Four years ago, Liu Xuesong Master are reduced to the first to grab the garbage scavengers, they need to solve the problem of the shortage of raw material. Liu Xuesong worked for a well-known Japanese fashion company, and was interviewed by fashion magazines 10 years ago. By coincidence, adding itmake. At that time, the company has only two executives, another executive Yang Guangze started building traditional materials, must be in line management, manufacturing. As a result, Liu Xuesong, who is enthusiastic about going into the branding campaign, is being pushed to the forefront of recycling. "It was crazy at that time."!" Liu Xuesong told reporters, "for all recycling enterprises, the supply shortage is pain point."." Because itmake the empty bottle recycling, environmental protection will be a lot of zero discharge and dust, the processing cost is higher than others, so the empty bottle recycling price is not competitive in the market. Its design capacity is 50 thousand tons, a year of recovery rate is only more than 20 thousand tons. The machine needs to start with nitrogen at 280 degrees, once started will not stop, because of the shortage of raw materials, itmake a shutdown losses of more than 100 thousand.

- Q: That's the kind of machine that can recycle plastic waste and process it into plastic particles. I don't know what kind of machinery it can work or need!

- I'm from Linyi. I sell plastic particle processing machinery. We Linyi do a lot of waste plastics processing particles,

- Q: Automatic scraps recycling machine is what how to use?

- So I closed plastic garbage collection machine by using direct injection of its new product when material re used currently to make Ji machinery push full self closing machine material

- Q: What kind of equipment should be used to recycle waste plastics such as bronzing film?

- Bronzing film, the most important thing is to rub. That's easy to fall off. Difficult is the aluminized film, need to use NAOH with high temperature..

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Board Foam Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 4 Sets Per Quarter set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords