CMAX Double Steps TypePP /PE Thin Film & PP Woven Bag Recycling Pelletizing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Item: PP PE thin film and PP woven bag plastic recycling pelletizing machines

1. Our advantages

We are plastic machinery manufacturer and can provide you machines at competitive price.

Our Machines are worthy of trust, for we have been in this field for over 10 years and our machines are CE certified.

Our company is not far away from Shanghai, which is convenient for us to deliver machines.

2. Application

Our PP PE thin film and PP woven bag plastic recycling pelletizing machines is an ideal equipment for recycling plastic film, bag, bit, belt, sheet or others (thickness below 0.5mm) such as pp pe

3. Features

This PP PE thin film and PP woven bag plastic recycling pelletizing machines is one of our hot sale products with the following features.

Safe in Operation------CE certified

High Quality and Durable------Materials are selected with care

Good Performance and Hot Sale------Low niose, low power consumption, high output and easy to operate

4. Configration and Parameter

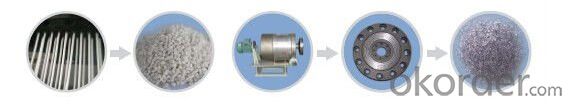

This PP PE thin film and PP woven bag plastic recycling pelletizing machines consists of belt conveyor, agglomerator, single screw extruder, degassing system, screen changer, die, die-cutting & dewatering system and air blower & silo unit.

Technical paramete

Model | Screw dia.(mm) | Motor Power (Kw) | L/D | Sub machine Model | Screw dia.(mm) | Motor power (kw) | L/D | Output | |

CAMX-100 | 100 | 55-75 | 34/1 | CAMX-100 | 100 | 22-30 | 9/1 | >=100 | |

CAMX-120 | 120 | 75-132 | 34/1 | CAMX-120 | 120 | 37-45 | 9/1 | >=250 | |

CAMX-150 | 150 | 110-160 | 34/1 | CAMX-150 | 150 | 45-75 | 9/1 | >=400 | |

CAMX-200 | 200 | 160-250 | 34/1 | CAMX-200 | 200 | 55-110 | 9/1 | >=600 |

Double Steps Type PP/PE Thin Film And PP Woven Bag Recycling Pelletizing Machine

This film recycling and pelletizing machine composed by two extruders, is good for recycling the raw materials which have much moisture such as film, foamed materials. The double-vent system increases the degasification volume. And the force feeding system ensures the higher production capacity.

Our Services

The Photo of Double Steps Type PP/PE Thin Film And PP Woven Bag Recycling Pelletizing Machine

Packaging & Shipping

- Q: Waste plastics granulation EIA Report Sample

- The EIA form is also availableChasing the answerIn general, you are doing this project EIA tableSee what you'll do later

- Q: Is environmental protection approved for plastic granulation?

- According to the provisions of the "construction project environmental impact assessment classification management directory", plastic products manufacturing in artificial leather, foam rubber involving toxic materials; a plating process requires the preparation of the EIA report; the rest of the need for the preparation of the EIA report table.

- Q: How about the granulator?

- My company is located in the scenic Jiangnan Water City, industrial star city - Changzhou, located in Shanghai and Nanjing Economic Development Zone hinterland, pleasant climate and convenient transportation. The company has strong technical force, perfect testing system, precise processing equipment and strict management system.

- Q: What's the fabric of the plastic bread machine?! What's in the cloth?

- The plastic granulator is made of glass fiber cloth, which plays an insulating role. Inside the cloth is an electric heating wire used to heat the barrel and melt the plastic.

- Q: How much will it cost to invest in the recycled plastic particle production line?

- Price: 330000 yuanModel / specification: LGHB-ZL220Power: 75Product Name: plastic granule machine, plastic granulatorApplicable materials: PE, PP, BOPP, HDPE, PA, CPP, PS, PVC and so onCapacity: 100-500After sale service: 1 yearsProduct parameter:1. output: 100-500 kg / h2. applicable materials: PE, PP, BOPP, HDPE, PA, CPP, PS, PVC, etc.3., the latest design of pneumatic particle cutting device, plastic particles more substantial, plump.

- Q: how much the price, I hope to know a friend told me Oh, thank you ah!

- We have been committed to the research and development of plastic extrusion machinery technology, the market for plastic extruder universal low productivity and short service life, high power consumption, in the mechanical design, according to the needs of different customers and different raw materials, developed separation screw, high mixing screw, machine tube technology KIV and with the use of hard tooth, mute type reducer, effectively solve these problems, the effective capacity of extruder with same specification and same type of plastic will increase from 20% to 30%, the actual power consumption is reduced by about 20%, the real implementation of the high capacity, long service life and low power consumption.In some developed countries, foreign enterprises and joint ventures on the type of environmental protection requirements, including noise control, exhaust gas treatment, closed the smoke, dust, and different frequency voltage, motor, we can achieve the design and manufacturing requirements.We follow the requirements of ISO9001 quality control system, establish a complete and standardized internal technical standards and quality control procedures, control point from the whole process of pre-sales service to product design, manufacturing, customer service service, to create a full range of its product quality, we have a number of years engaged in plastic granulator research and development, manufacturing and service a professional engineering team and staff, provide a solid guarantee for the customer confidence.

- Q: May I ask who knows the plastic granulator manufacturers contact ~ figure

- China is the same, who knows who ah?. Otherwise, better contact

- Q: What plastic particles are used for wire injection? How much would you like to invest in a plastic pelleting plant?

- Plastic granulation plant can also be large, small, small, about 100000, about 200000 of the general, large, millions of normal.

- Q: How can the granulator recycle the plastic bottle?

- After shredding, polyester slices are washed to remove residues, labels, and other contaminants. Once cleaned, the polyester slices are then prepared to reduce to smaller particles called flakes. Flake, usually produced by other size requirements, reduces a granulator. A granulator is significantly different than a shredder. The granulator runs at a slow pace and is designed to be suitable for washing various chips of irregular sizes. A granulator is a high speed machine designed to produce a sheet of concrete sizes suitable for recycling to many of the products listed above. Here is a good example of granulation used in this applicationWith the above granulation sorting process, the other countries also advocate environmental protection, waste recycling.

- Q: How to solve the noise of plastic granulator

- I suggest you cover your ears and solve it.

Send your message to us

CMAX Double Steps TypePP /PE Thin Film & PP Woven Bag Recycling Pelletizing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords