Posa Geomembrane Compound Geomembrane Composite with Two Geotextiles and One Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

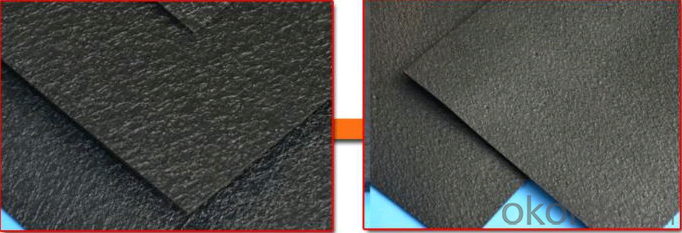

Geomembranes are generally considered to be made from continuous, highly impermeable, extruded flexible sheets of either HDPE (High Density Polyethylene) or LDPE (Low Density Polyethylene). However, it is also possible to tightly weave small tape fibres of these polymers so as to achieve (either directly or by subsequent treatment) an impermeable membrane. Predominantly, the continuous extruded sheets are used for water containment or waste disposal linings. These inevitably involve the lining of soil slopes and, in order to increase the frictional characteristics of the membranes, so as to resist sliding, one or both sides of geomembranes can be provided with roughened or raised profile surfaces.

Applications:

Geomembranes have a very low coefficient of permeability - much lower than most clays and natural soils. HDPE, in particular, is highly resistant to any form of chemical or biological attack. It is also very resistant to U.V. degradation. Many geomembranes are so inert that they cannot be glued together - the chemical reactions of adhesives do not work on them - they have to be welded together by heat. Their inert nature and long life characteristics make HDPE geomembranes ideal to act as liners for liquid chemical reservoirs, fresh-water reservoirs, animal waste containers, basal linings and top capping layers for waste disposal sites. During installation, HDPE geomembrane edges are sealed to one another with a double heat welded joint. The gap between the two welds is checked for leakage using an air pressure test. Many users consider that HDPE is the ideal material for the purpose of lining water and waste disposal sites because of its proven long term stability and resistance to chemical attack, but in addition to HDPE, there is LDPE, for less demanding applications such as fresh water retention and a membrane reinforced with a polyester reinforcing fabric for use where higher in-plane stresses have to be absorbed.

No. | Item | Test Value | |||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 1.8mm | 2.0mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.94 | |||||||

2 | Strength at yield,N/mm | 11 | 15 | 18 | 23 | 27 | 30 | 38 | 45 |

3 | Strength at break ,N/mm | 21 | 28 | 33 | 43 | 51 | 57 | 71 | 85 |

4 | Elongation at yield,% | 13 | |||||||

5 | Elongation at break,% | 700min | |||||||

6 | Tear Resistance N | 93 | 125 | 156 | 187 | 219 | 249 | 311 | 373 |

7 | Puncture Resistance N | 263 | 352 | 440 | 530 | 618 | 703 | 881 | 1059 |

8 | Stress Crack Resistance, hrs | 400 | |||||||

9 | Carbon Black Content, % | 2.0-3.0 | |||||||

Carbon Black Dispersion | 1 or 2 | ||||||||

10 | Standard OTI Min | 100 | |||||||

High Pressure OTI Min | 400 | ||||||||

11 | Impact Cold Crack at -70°C | Pass | |||||||

12 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | |||||||

13 | Dimensional Stability (%) | ±2 | |||||||

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: What is the difference between the unidirectional geogrid and the bidirectional geogrid?

- Unidirectional geogrid is shaped by stretching in one direction and has thin rectangular mesh. Bidirectional geogrid is made by stretching in two directions. It is of net?structure with square mesh. The structure of unidirectional geogrid has really high tensile strength and tensile modulus that the strength of extension reaches 100 to 200Mpa. It is close to the level of mild steel and much better than the traditional or existing reinforced materials. 1) Bidirectional geogrid can increase the bearing capacity and the service life of the roadbed (foundation). It can take the place of metal net and be used as the top mesh in the mine.

- Q: How do geomembranes handle wave action?

- Geomembranes are designed to handle wave action by providing a durable and impermeable barrier between water bodies and their surroundings. They have high tensile strength and flexibility, allowing them to withstand the dynamic forces exerted by waves. Additionally, the smooth surface of geomembranes reduces the potential for wave-induced erosion, ensuring the stability and integrity of the structure.

- Q: What's the principle of diaphragm valve?

- Principle: Power drive screw with compressed air to make valve element move up and down and pull mebrane up and down movement to turn it off and on. Features: compact, simple, small, beautiful; switch with guide, smooth motion; little closing moment, long life, ≥30 million times; mebrane compaction can be automatically adjusted for uniform pressure and reliable sealing; install mebrane into valve element through pushing-in method which is easy to replace.

- Q: How to weld the geomembrane better?

- When the temperature is below 5 degrees Celsius, construction should not begin in accordance with the requirements of the specification. If the construction must begin, the welding machine should be preheated before welding. 6 4 the welding line must be neat and beautiful, and there must be no slide welding and hopping. When the geomembrane is laid, telescopic deformation caused by temperature change should be reserved according to the varied range of local temperature and the properties of the geomembrane. 2 The joint of the geomembrane must not have oil as well as dust and the overlapping section of the geomembrane should not be have debris like sand and mud. The debris must be cleaned before welding. 12 the welding line of adjacent welding seam should be lapped staggerly. 9 Before the welding starts everyday, a sample of 0.9mm×0.3mm should be test welded on the scene. 5 13 When welding the geomembrane, electric generator of great voltage regulation performance should be used to supply power and voltage?stabilizer must be used when using local electricity under special conditions.

- Q: Are geomembranes resistant to microbial growth?

- Yes, geomembranes are generally resistant to microbial growth. The impermeable nature of geomembranes and their resistance to degradation make it difficult for microorganisms to grow on their surface. However, it is important to note that the presence of moisture, nutrients, and certain environmental conditions can still lead to microbial growth over time.

- Q: What are the considerations for geomembrane selection in oil and gas exploration sites?

- Some considerations for geomembrane selection in oil and gas exploration sites include the chemical resistance of the geomembrane to potential contaminants found in the soil or water, the strength and durability of the material to withstand the harsh conditions of the site, the flexibility of the geomembrane to conform to irregular surfaces, and the overall cost-effectiveness of the chosen material. Additionally, factors such as installation requirements, environmental regulations, and the project timeline may also influence the selection process.

- Q: Which one is better, oil heater or electrothermal?film?

- The oil heater is heated slowly and will take up the space. The electrothermal?film is heated quickly and its heat range is large. The biggest advantage of it is that it does not take up any interior space as it is laid directly under the floor. It a good chioce for getting warm in winter. Meanwhile, the far-infrared carbon fiber of the electrothermal?film can as can effectively promote blood circulation. It is healthy and environmentally friendly!

- Q: How do geomembranes contribute to the preservation of coral reefs?

- Geomembranes contribute to the preservation of coral reefs by acting as a protective barrier between human activities and the delicate marine ecosystem. They prevent the leakage of hazardous materials, such as pollutants and chemicals, into the surrounding waters, reducing the risk of pollution and contamination that can harm coral reefs. Geomembranes also provide a barrier against physical damage caused by construction or development near coral reefs, helping to maintain their structural integrity and biodiversity.

- Q: How do geomembranes help with pond lining?

- Geomembranes help with pond lining by providing a durable and impermeable barrier that prevents water seepage and leakage. They act as a protective lining for the pond, ensuring that water stays contained and does not infiltrate the surrounding soil. Additionally, geomembranes help to prevent the loss of water through evaporation, thus reducing the need for frequent refilling.

Send your message to us

Posa Geomembrane Compound Geomembrane Composite with Two Geotextiles and One Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords