Eco-friendly 100pp nonwoven polyester spunbond non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

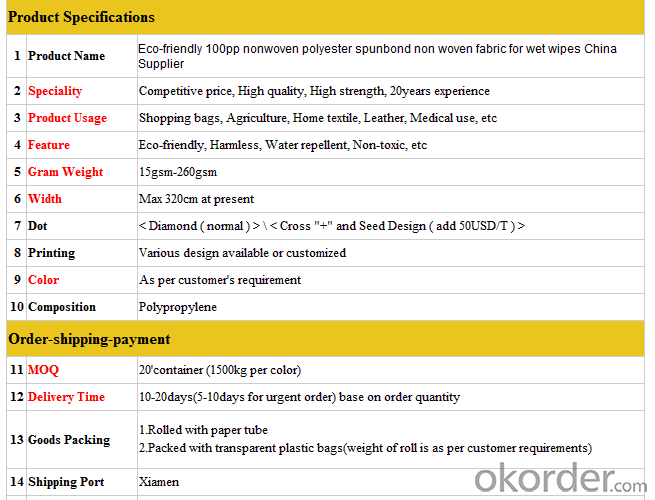

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What kind of fiber can be used as textile fiber

- Can be used as textile fibers with natural fibers and chemical fibers. 1, natural fiber source is divided into plant fiber and animal fiber, plant fiber, plant fiber is natural cellulose fiber

- Q: Lin is what kind of textile

- Second, the identification of fiber 1, identification methods: ① identification methods are feel, visual method, combustion, microscopy, dissolution method, drug coloring method and infrared spectroscopy.

- Q: What is the meaning of TOP in the textile industry?

- 50D T + 20D OP, 50D polyester filament + 20D spandex, OP is the meaning of spandex. T is polyester.

- Q: What are the textiles?

- Clothing textiles, including the production of clothing and a variety of textile fabrics and sewing thread, elastic, lined, lining and other kinds of textile accessories and knitted garments, gloves, socks and so on.

- Q: Textile printing and dyeing process which

- Although dyeing can be done through a rolling mill, but also the most difficult process, because the color control of dyeing in addition to the known, there are many uncertainties, such as the stability of the dye at different temperatures, steam control , Rolling pressure control, etc., are very fine live ..

- Q: What are the problems with the transformation and upgrading of the processing trade of textile enterprises?

- I think this is clearly the focus of the "revitalization plan". It is worth noting that the "revitalization plan" has made clear the "textile industry is the traditional pillar industry of China's national economy and an important livelihood of the industry, but also the international competitive advantage of the industry

- Q: China textile products do not how points? What kind of?

- Jiangsu, Zhejiang and Shanghai textile industry's outstanding characteristics of Jiangsu and Zhejiang textile industry momentum of development, the pace of upgrading and upgrading, so that we are deeply shocked, popular inspired. To sum up, Jiangsu, Zhejiang and Shanghai textile industry has the following characteristics

- Q: Is there a large yarn factory or a textile garment factory?

- Textile: the subject is too large, including textile raw materials production, spinning, weaving, printing and dyeing, finishing, and then into the clothing link.

- Q: What is eco textile?

- From the perspective of production ecology, control, including from the fiber cultivation, breeding, production to the whole process of product processing on the environment pollution, the product itself is not "pollution"

- Q: How does the chemical composition of the textile be analyzed?

- PH value, formaldehyde content, lead content, azo dye test, heavy metal content test, water absorption, moisture content, odor, cotton mercerizing effect, hot pressing, dry heat, storage sublimation, acid spots, Spots, phenolic yellowing and so on.

Send your message to us

Eco-friendly 100pp nonwoven polyester spunbond non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords