PP Liquid filter bag for water treatment and water purification

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

PP filter bag(Micron Polypropylene filter fabric) have a lower fiber release, more defined pore size and greater retention efficiency than other filter media(filter bag). Liquid PP filter bag offer high efficiency filtration and have a high solids catch capacity. Produce micron Polypropylene filter bags have their outside surface singed or glazed to prevent fabric fiber from the bag getting into the clean,filter process media. Micron PP filter bags are generally compatible with most fluids except those considered aromatic solvents or strongly alkaline.Liquid PP filter fabric(liquid PP filter bags) are recommended for prefiltering acids,aqueous and most solvent solutions.

Polyester fibers are compressed and finishes are applied according to the process or application they are used for.All of the excellent characteristics of polyester apply to polyester felt, including good resistance to chemicals, abrasion and dry heat degradation, plus excellent dimensional stability

Application

l Automotive coatings and paints

l water purification and water treatment

l pharmaceutical

l food and beverage

l fine chemical industry

l Electronics

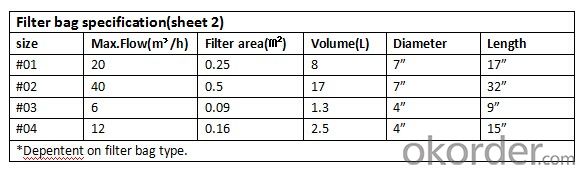

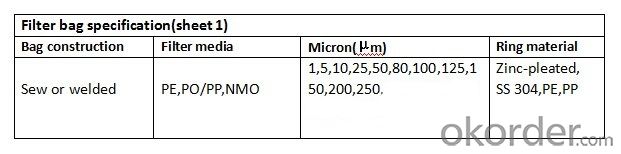

Specifications

- Q: the net friend says can do it yourself, but the others can card in, but mine is sticky, what glue is not afraid of water?

- Two ways:Buy one directly.In fact, this can be bought in many places, and the price is not expensive. Should pay attention to the size of the problem, as far as possible to communicate with the seller clear, so as not to buy, can not be installed on the use.

- Q: How is the filter bag precision divided?

- There are pore size, usually 15, 25, 50, 100, electrophoresis coating, usually 25 and 50 (microns).

- Q: To know the market direction of the equipment for the sale of filtration products, please understand the instructions of our products

- Many industries have used filter bags, filters, such as: food, beverages, electroplating, pharmaceuticals, ceramics, hospitals and so on can be used. According to different requirements, you can make special custom-made.

- Q: Where is the filter bag in the Little Swan Washing machine?

- Friends, you go to the small Swan Washing machine store to see, maybe repair shop will also have.

- Q: The filter bag in the washing machine is not available. Can I use it?

- Can be used, if you can buy, it is best to install, and if there are impurities in clothing, thread, etc., will twine the impeller, affecting motor rotation.

- Q: Which filter or filter paper has a better filtration effect?

- Filter bag filter effect is good, filter bag accuracy range: 0.1-500 microns, the highest filtration efficiency can reach 99.99%. The conventional filtration efficiency is about 95%.

- Q: How many kinds of cloth bags are there in the dust collector?

- 2, twill: is made up of two, four under the root and at the same time warp and weft interwoven warp and weft move gradually to the left or right; single and double sided twill weave twill twill twill; flexibility and elasticity are better than plain cloth, the mechanical strength is slightly lower, after the stress displacement, but its good abrasion resistance, dust removal efficiency and the cleaning effect is good, is a kind of woven filter tissue is the most commonly used;

- Q: From what considerations, you can easily choose dust filter bag?

- First of all, to understand the flue gas temperature: the filter can not adapt to the flue gas temperature is very important. If the normal use temperature of filter materials is lower than the temperature of the flue gas, it may cause the bag to be burned out and cause great economic losses. Then, how to select the filter material according to the flue gas temperature? Filter material according to the use of temperature is divided into: normal temperature filter materials below 130 degrees Celsius, medium temperature filter materials 130~180 degrees Celsius, high temperature filter material 180~280 degrees celsius. Know the temperature of the flue gas and the use temperature of the filter material, is the filter material can be selected?.The second step is to understand the composition of the smoke: This includes dust content, specific gravity, particle size, viscosity, smoke water content and other parameters. By understanding these decisions, the dust removal method, the post treatment method and the filtration velocity of the filter materials are presented. Under normal circumstances, large amount of dust, dust relatively sticky and light conditions choose pulse bag filter, filter wind speed most of the control in more than 1.2m/min, a few in 1m/min below.The third step is to understand the amount of flue gas that needs to be handled: the amount of air treated by the dust collector is usually the volume of the working air and the coefficient of air leakage (10%~15%). Know the dust handling air flow, filter wind speed, you can get the total filtration area by formula: S = Q/60V. Where S: total filtration area Q: system handling air V: filter wind speed.

- Q: Dust filter bag how to maintain daily?

- 3, in dealing with high temperature smoke, as far as possible to use high temperature dust collection bag, high temperature dust bag, can better prevent the phenomenon of not burning, also can make the bag life longer.4, to prevent the filter bag filter bag aging, aging problem is generally life long, or is caused by the external environment, for example, dedusting equipment leads to abnormal high temperature cloth shrinkage deformation, hardening, contact with acid and alkali and other corrosive gases, and may react with the surrounding material. It requires us to strengthen the management of the working environment of the filter bag, reduce the chance of exposure to harmful substances, standardize the operation of dust removal equipment, and reduce the working temperature.

- Q: How is the quoted price of filter bags in the filter bag factory calculated?

- Look at the filter bag material, different materials, prices are different.

Send your message to us

PP Liquid filter bag for water treatment and water purification

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches