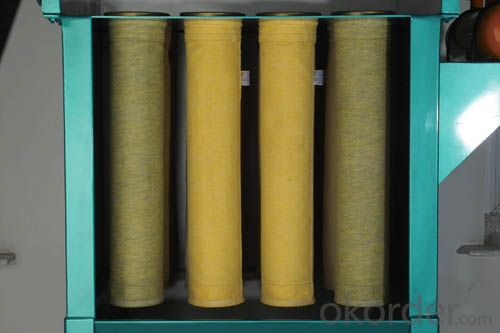

Cement dust filter bags made of needle felt

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cement industry-High temperature and corrosion resistance filter media

In the cement industry, our main products are polyimide series bag filters, aramid series bag filters, polyester series bag filters, glassfiber woven bag filters, MTS bag filters, which are used in many large cement plants in

We use different treatment according to the specific conditions of cement kiln

We pursue quality products, reasonable price and excellent service.

When you choose to use the products of our company, you only need to call or write to the company, we will solve all you troubles and give you a satisfactory results.

Dust Filter Bags Used For Cement Kiln

Abrasive dust, high gas temperatures and aggressive gas composition are the most important points to be considered for the selection of a suitable filter medium. Continuous high temperature combined with active gas composition will cause the chemical corrosion of the filter material gradually. It is a big problem to avoid the hydrolysis and oxidation. We choose to use polyimide fiber made filter material.

Polyimide fiber can stand temperature from 220 to 260.and it has good resistance hydrolysis, oxidation and acids. It has irregular fiber cross section which is advantageous under aspects of dust filtration

We pursue quality products, reasonable price and excellent service.

When you choose to use the products of our company, you only need to call or write to the company, we will solve all you troubles and give you a satisfactory results.

- Q: What about the cooling performance of industrial refrigerators?

- screw type refrigerator ventilation is not smooth. The heat transfer effect of the evaporator is poor, and the refrigerant is evaporated, and continues to evaporate in the air return pipe and the compressor. Therefore,

- Q: Mass production process, equipment and budget for industrial calcium chloride

- Granulation method of CN00819725.3 calcium chloride hydrate and granulation device in the flowing layer 1, which is at the edge of particle flow, from pellet spray nozzle spray 8 calcium chloride aqueous solution of calcium chloride hydrate formation, at least according to the determination of the temperature sensor T<sub>1</ and sub> determination of flow within layer

- Q: Can industrial water filters be filtered by domestic water?

- filter: completely remove the beneficial and harmful substances in water, the output is pure water. Pressure and electricity are needed, the utilization rate of water is low (more waste water, less pure water), and about 50% of the tap water is wasted. High purification costs, small flow, only solve the problem of drinking water.

- Q: Introduction of iron and manganese filter

- The device uses the aeration oxidation, iron and manganese and manganese sand principle catalysis, adsorption and filtration

- Q: What is the principle of industrial dust collector?

- Filter type dust removing device including industrial dust collector and the granular layer of industrial dust collector, the former usually use organic or inorganic fiber fabric made of the filter as the filter layer, filtering layer and the latter with different diameter particles, such as quartz sand, river sand, slag ceramsite, etc..

- Q: What's the process of starting a mineral water company?

- Third, there are three forms of registration

- Q: Where is the manufacturer of pure water equipment?

- The pretreatment system, reverse osmosis system, intermediate water tank, coarse to fine mixed bed and mixed bed of pure water tank, water pump, UV sterilizer, precision filter, water polishing resin, the object (more than 18M Omega.CM) (traditional technology)

- Q: What functions can screening equipment play in industry?

- filtering, cleaning materials, simple is the impurities in the material will remove or substandard products to ensure the quality of products.

- Q: How can the filter core of the filter installed in the industrial pipe installation be fixed? Seek professional answers

- The industrial pipeline is divided into low pressure pipe, pressure pipe, high-pressure pipeline and high pressure pipeline

- Q: What equipment is used for oil (cooling) in filtration equipment?

- adding the third element in the two yuan in the alloy, will change the solubility of the original alloy component, or even a new phase of the new generation phase transition.

Send your message to us

Cement dust filter bags made of needle felt

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches