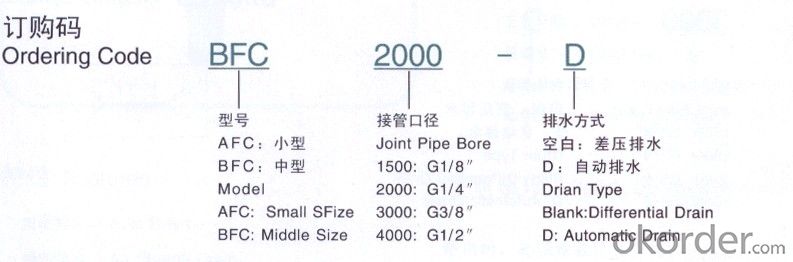

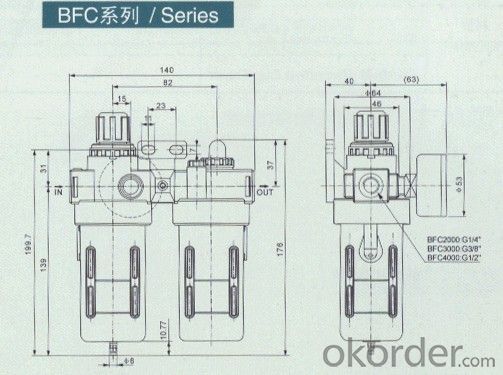

air source treatment percolator leachair filter,pressure regulator,pneumatic BFC-4000 1“

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

free to adjust the pressure range ,reduce the impurity of air .oil and water seperator .

best solution for automation . strict quality and cost control system !

feature :1.simple assemble,instructure simple ,use to all kinds of automatic equipment .

2.sugest oil : VG32

3.pay attention to the temperation range and pressure range .

advantage: 1.new oil cap to ensure the oil will not come out .

2.new adjust pressure cap ( when pressure high will not come out)

3. bigger flow rate and less noise .

production ability : 1. one month 10000pcs

2. 150 workers

3 .advanced machine ,professional technician team

4. 4.delivery date :normally 15-20days .

2.sugest oil : VG32

3.pay attention to the temperation range and pressure range .

advantage: 1.new oil cap to ensure the oil will not come out .

2.new adjust pressure cap ( when pressure high will not come out)

3. bigger flow rate and less noise .

production ability : 1. one month 10000pcs

2. 150 workers

3 .advanced machine ,professional technician team

4. 4.delivery date :normally 15-20days .

best solution for automation most professional manufacture for pneumatic !

- Q: Development of pneumatic components,The expansion of application of pneumatic technology is the development of pneumatic industry

- The expansion of application of pneumatic technology is the sign of pneumatic industry development. The application of pneumatic components mainly includes two aspects: maintenance and matching. In the past, the sales of domestic pneumatic components were used for maintenance, and in recent years, the sales share directly as the main supporting parts increased year by year. The use of domestic pneumatic components, from tens of thousands of dollars worth of metallurgical equipment to only 1~2 hundred yuan chair. Railway switches, locomotive wheel rail lubrication, train brake, street cleaning, hoisting equipment in special workshops, military command vehicles, etc., have been specially developed domestic pneumatic components. This shows that pneumatic technology has penetrated into all walks of life and is expanding.Although China's pneumatic industry has reached a certain scale and technical level, but compared with the international advanced level, the gap is great. China's output value of pneumatic products accounted for only 1.3% of the world's total output value, only the United States 1/21, Japan's 1/15, Germany's 1/8. This is out of proportion with the big country of about 1000000000 people. From a variety point of view, a Japanese company has 6500 varieties, China has only its 1/5. Product performance and quality level gap is also great.The pneumatic technology is increasingly applied in the automatic assembly of various industries and automatic processing of small, special items of equipment, the original traditional pneumatic components is increasing, and continue to develop new products to meet market demand, the variety of pneumatic components is increasing, the trend of its development are mainly in the following aspects:

- Q: I've never touched this piece of pneumatic components. How do I get started?

- 1, first find the book entry materials gas technology at recommended SMC practical modern pneumatic technology is a book, more user-friendly and comprehensive, clear main pneumatic components, such as filter, solenoid valve, cylinder, understand the use, shape, broadly divided into categories, do not need to look at theory and calculation.2, check the object, in the dealer or factory to see what pneumatic components, focusing on the use of the original, and gradually form the concept of pneumatic systems.

- Q: What is the difference between pneumatic components PC8-03 and PC8-02?

- Do you mean the connection? If it's the joint, 02 refers to PT1/4, and the 03 refers to the PT3/8, the joint is one side of the pipe and the thread, and the two are inserted into the 8 pipe

- Q: Pneumatic components, three bit, five - way, can you explain?

- Five way: solenoid valve has 5 vents (usually 1 gas supply port P, 2 use mouth A, B, 2 exhaust port EA, EB)Above! A mouthful, slowly look at yourself

- Q: Pneumatic oil filter oil in what

- Pneumatic filter (also known as oil-water separator), the role is to filter out from the compressed air source of water, oil, gas, dust impurities, so that air purification of pneumatic components. Transparent cup on the device (you can refer to, is not) inside the gas, impurities is filtered by the temporary storage. There are too many filters that need to be removed.

- Q: What is the gas in the two pneumatic combination?

- Now most of the cylinder, valve generally in the pneumatic components of the pre sliding parts parts into the semi-solid grease like (or paste oil) called non oil components. Therefore, there is no need to provide oil mist lubrication in such pneumatic transmission. If the oil mist lubrication to non oil pneumatic components, not only has no meaning, and semi solid lubricating grease is very thin oil mist and oil slowly dilute the sealed gas loss is bad. If oil mist has been supplied, keep it up.

- Q: What are the common pneumatic components?

- Two 、 triple filtration, cylinder, trachea, trachea joint, solenoid valve, air control valve, foot valve, hand valve, buffer, throttle valve, voltage regulator

- Q: Pneumatic solenoid valve base blind plate leak is how?

- 3. check the connection and muffler is damaged, if the maintenance trouble, you can consider replacing one, there is not much money

- Q: What elements are most common in pneumatic?

- The most common should belong to the jointOur company specializes in the production of high-end white connector, CNC lathe

- Q: Pneumatic components, those equipment needs to be used, specific points. Additional reward

- It must be the executing agency. If you want to do such sales, you can run automated equipment, automated assembly line manufacturers, such companies, pneumatic components should be used more!!

Send your message to us

air source treatment percolator leachair filter,pressure regulator,pneumatic BFC-4000 1“

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords