Pliable Aluminum Sheets - Steel Rolled Coil SS400 Q345 Q195 Hot Rolled Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

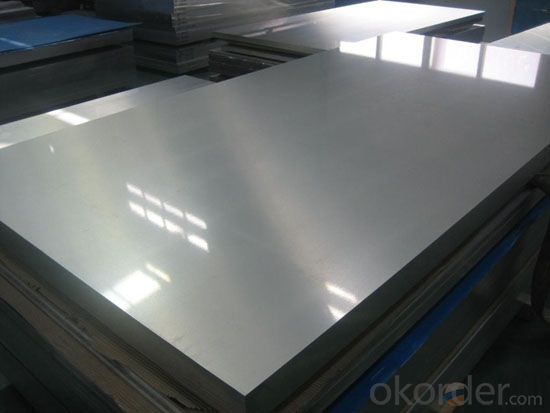

General Information of Cold Rolled Steel Sheet

The raw material of cold rolled steel sheet is high quality hot rolled product, and after pickling, continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as processing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

Specifications of Cold Rolled Steel Sheet

1) Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing

2) Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

3) Thickness: 0.20mm - 3.0mm

4) Width: 600/1000/1250/1500 (mm) or per customer's request

Package of Cold Rolled Steel Sheet

Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

Applications of Cold Rolled Steel Sheet

1) For the further producing of hot dip galvanized steel products

2) Cold rolled Steel: Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

- Q: Are aluminum sheets resistant to rust?

- Indeed, the resistance of aluminum sheets to rust is remarkably high. This is due to the natural formation of a protective oxide layer on the surface of aluminum when it comes into contact with air, thereby hindering further corrosion. In contrast to iron or steel that can rust in the presence of moisture and oxygen, aluminum does not necessitate any supplementary coatings or treatments to safeguard against rust formation. Consequently, aluminum sheets are widely favored across various sectors such as construction, automotive, and marine industries, where the prevention of rust is imperative.

- Q: This question asks for a method to determine the quantity of aluminum sheets required for a specific project.

- <p>To calculate the amount of aluminum sheets needed for a project, first determine the area that needs to be covered. Measure the length and width of the surface in question. Multiply these two dimensions to get the total area in square units (e.g., square feet or square meters). Next, consider the thickness and specific requirements of the aluminum sheets, as this may affect the number of sheets needed. Finally, divide the total area by the coverage area of one aluminum sheet (which can be found from the supplier or calculated if you know the dimensions and thickness of a single sheet). Round up to the nearest whole number to ensure you have enough material for your project. Always account for waste and additional material for cuts or adjustments.</p>

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- You have thought about it carefully, you can't use aluminum foil.

- Q: What are the different alloy compositions available for aluminum sheets?

- There are several alloy compositions available for aluminum sheets, each with its own unique properties and applications. Some common alloy compositions include: 1. 1100: This alloy is known for its excellent corrosion resistance and high thermal conductivity. It is often used in chemical equipment, heat exchangers, and food processing equipment. 2. 3003: This alloy has good formability, moderate strength, and excellent corrosion resistance. It is commonly used in packaging, tanks, and architectural applications. 3. 5052: This alloy is known for its high strength and good formability. It is often used in marine applications, as well as in aircraft and automotive parts. 4. 6061: This alloy has excellent strength, good formability, and high corrosion resistance. It is commonly used in structural applications, such as in bridges, buildings, and transportation equipment. 5. 7075: This alloy is known for its extremely high strength and good machinability. It is often used in aerospace applications, as well as in high-stress parts for the automotive and sporting goods industries. These are just a few examples of the many alloy compositions available for aluminum sheets. The choice of alloy will depend on the specific requirements of the application, such as strength, corrosion resistance, formability, and machinability.

- Q: Can aluminum sheets be recycled?

- Yes, aluminum sheets can be recycled. Aluminum is one of the most commonly recycled materials in the world because it can be recycled indefinitely without losing its quality. Recycling aluminum sheets involves melting them down to their original state and then shaping them into new sheets or other aluminum products. This process requires significantly less energy compared to producing aluminum from raw materials, making recycling aluminum sheets an environmentally sustainable option.

- Q: How much should I be charged to have aluminum siding installed? I have a two floor single family home which is detached. I also would want new gutters installed and soffets (i think that is what they are called). One company estimated 12k and another said 10K. This would entail just putting the siding over the original siding. Any answers are appreciated.

- They don't make aluminum siding anymore, thank god, they only make vinyl siding. It really depends on the brand you buy and the company that installs it. I used to be a tin man before becoming a professor and I can tell you that you should do a little research first. You want stuff that will hold up in wind, is easy to clean, has a nice look and colors won't fade. You want to be sure it is made of virgin vinyl, sounds weird but trust me, if it isn't it'll fade in a few years and look like crap. The company needs to know what they are doing too or the seams and lines will be terrible, so make sure your company is really in the siding business and not just some jack-leg contractor that says I can do it. You will end up with a crap job. Now I can't remember for certain and it has been a number of years, but 10 to 12 sounds good. I hope they are going to remove the old stuff, check your wood underneath and possibly put on a moisture barrier. I would ask what they plan on doing in detail. Good luck.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation to some extent. While aluminum is not the best material for soundproofing compared to others like rubber or foam, it can still provide some level of sound insulation when used correctly. Aluminum sheets can be installed as a barrier or partition in walls, ceilings, floors, or other surfaces to reduce the transmission of sound waves. However, it is important to note that additional soundproofing materials or techniques might be necessary to achieve optimal results.

- Q: Are aluminum sheets resistant to UV rays?

- Yes, aluminum sheets are generally resistant to UV rays.

- Q: Can aluminum sheets be used for fencing?

- Yes, aluminum sheets can be used for fencing. Aluminum is a lightweight and durable material, making it suitable for fencing purposes. It is resistant to rust and corrosion, making it a long-lasting option. Additionally, aluminum sheets offer a sleek and modern look to any fence.

- Q: What are the advantages of using aluminum sheets over other materials?

- There are several advantages of using aluminum sheets over other materials. Firstly, aluminum is lightweight, making it easier to handle and transport. Additionally, aluminum is highly resistant to corrosion, which increases its durability and lifespan. Aluminum sheets also have excellent thermal and electrical conductivity, making them suitable for various applications. Moreover, aluminum is highly malleable, allowing it to be easily formed into different shapes and sizes. Lastly, aluminum is a sustainable and recyclable material, contributing to environmental benefits.

Send your message to us

Pliable Aluminum Sheets - Steel Rolled Coil SS400 Q345 Q195 Hot Rolled Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords