Plastic Tubes - PPR Plastic Pipe China Professional Pipe Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 ft

- Supply Capability:

- 10000 ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems.

Advantages:

1. Greatly reduced linear expansion coefficient, only 1/4 of that of PPR.

2. 100% oxygen tightness, suitable for heating systerm.

3. Improved resistant to impulse under low temperature, resistant to UV-rays.

4. Easily detected by detector when embedded, owing to the metal layer.

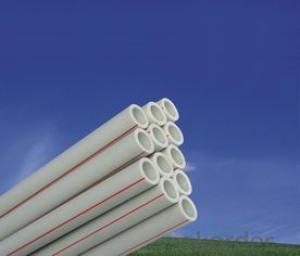

Picture of PPR

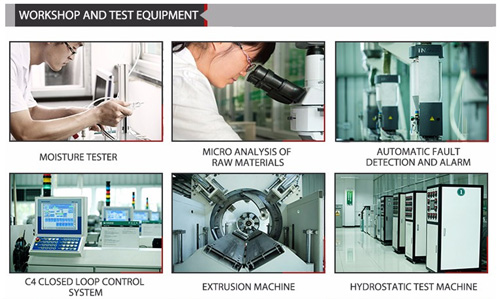

Factory

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,papal

Product Pictures

- Q: What are the common wall thicknesses for plastic tubes?

- The common wall thicknesses for plastic tubes can vary depending on the specific application and material used. However, some typical ranges include 0.5mm to 3mm for thin-walled tubes and 3mm to 8mm for thicker-walled tubes.

- Q: i leave my oil tubes in a clear plastic bin, but ive left it near the window and the sun hit em most of the day... but the tubes are like some sort of soft metal, maybe aluminum? So i mean, i know its never good to put anything in the sun for long, but the paints are in a tube where i think, sun wouldn't really affect em...as for heat. im not sure what that would do to em.

- I shouldn't affect it, unless it was really really boiling hot then i don't know if it would be very good. (40 degrees+) Other than that it should be fine!

- Q: Can plastic tubes be connected or joined together?

- Yes, plastic tubes can be connected or joined together using various methods such as adhesive bonding, heat fusion, compression fittings, or mechanical connectors.

- Q: Are plastic tubes resistant to freezing temperatures?

- No, plastic tubes are not typically resistant to freezing temperatures as they can become brittle and crack when exposed to extreme cold.

- Q: Are plastic tubes resistant to impact or cracking?

- Yes, plastic tubes are generally resistant to impact and cracking.

- Q: How flexible are plastic tubes?

- Plastic tubes can vary in flexibility depending on their composition, thickness, and intended use. Generally, plastic tubes can be quite flexible and can bend or twist to a certain extent without breaking. However, the flexibility can also be adjusted by using different types of plastics or by incorporating reinforcement materials.

- Q: I am looking for a lightweight, easy-to-tear, food-safe plastic to be used with a heat sealer to package homemade baked goods. More specifically, dipped pretzel rods. Ideally, a roll of narrow width would be best. That way, I can insert the pretzel and seal both short ends, and so on. There seems to be an abundance of the more rubbery polyethelene tubing available, but it is very difficult to break apart. Think Twinkie plastic. Suggestions would be greatly appreciated! Thanx.

- They also might be able to steer you to someone

- Q: Ok so I now have all my gear to go bass fishing and im using some soft plastic tubes and brush hogs mainly using a carolina rig. I will be fishing in lakes for small mouth and large mouth. After casting what are some good methods of retrieval for the lures other than just reeling it in. for instance should i pause for so many seconds after the bait hits the water then reel? or should i reel then pause for so many seconds then reel again?

- Bass WILL hit a motionless bait. With a carolina rig, it is all about keeping it on the bottom. Try to drag the weight on the bottom as much as possible, that makes noise, which attracts the fish. As far as how to reel it in, try a lot of different techniques until you get a bite, then try to duplicate what you were doing. But the most important thing with a c-rig is to keep that bait on the bottom, just drag it along, eventually something will grab it. Good luck.

- Q: How can the PPR pipe be connected with the metal tube?

- In the PP-R piping system, the transition between the metal pipe and the plastic pipe needs a transition piece, the transition piece and the PP-R pipe are connected by hot melt, and the transition part is connected with the metal pipe through a screw thread.

- Q: How are plastic tubes sealed to prevent leakage?

- Plastic tubes are sealed to prevent leakage through a variety of methods such as heat sealing, ultrasonic welding, crimping, or the use of caps and closures. These techniques ensure a secure and tight seal that prevents any liquid or substance from leaking out of the tube.

Send your message to us

Plastic Tubes - PPR Plastic Pipe China Professional Pipe Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 ft

- Supply Capability:

- 10000 ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords