Plastic Tubes - PPR Plastic Pipe China Professional Pipe Supplier in 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 ft

- Supply Capability:

- 10000 ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Irrigating system for gardens and green houses

4) Public and sport facilities such as swimming pools and stadiums

5) For rainwater utilization systems.

Advantages:

1. Greatly reduced linear expansion coefficient, only 1/4 of that of PPR.

2. 100% oxygen tightness, suitable for heating systerm.

3. Improved resistant to impulse under low temperature, resistant to UV-rays.

4. Easily detected by detector when embedded, owing to the metal layer.

Picture of PPR:

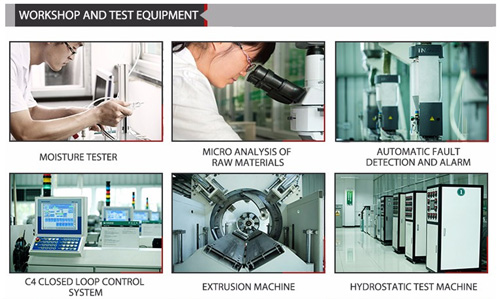

Factory

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,papal

- Q: I am doing a project and i have a plastic tube that need to go in circles so i need to straighten it. Any Ideas? I need this fast please. :)

- Blow dryer on high or a heat gun on low. The heat gun will be the most likely to work. Not knowing your age I will say that you can get your parents to put it in your oven and set the temp for say 170F or less and heat it for 3-6 min. That will soften it up but if your oven does not go that low forget that method. The oven method would be my last choice. Just thought of one. If you have a rice cooker or steamer that may work if it is big enough. The steam will heat it but not burn it. But again if you are a minor have your parents do it. This you will have to watch and again it would not be my first choice.

- Q: Are plastic tubes suitable for electrical conduit?

- No, plastic tubes are not suitable for electrical conduit. Electrical conduit needs to be made of materials that are fire-resistant, durable, and able to withstand high temperatures. Plastic tubes are not able to meet these requirements, making them unsuitable for use as electrical conduit.

- Q: Are plastic tubes biodegradable?

- No, plastic tubes are not biodegradable.

- Q: A piece of plastic tubing is 19 inches long and must be divided into 6 smaller pieces each at least 2 inches long. What is the largest length of tubing possible?

- the small ones are all 2 so 5 x 2 is10 19 minus 10 is 9 it is 9

- Q: I recently bought my house in the dead of winter while there was snow on the ground. The snow has recently melted and revealed that there is about a 6-8 inch plastic tube sticking out of a hole in my lawn. Anyone have any idea of what it is? It is flush with the grass and close to the sidewalk.

- Dig out inside the tube and see what you find. Some subdivisions have that type of protection for the water valves.

- Q: How do plastic tubes compare to stainless steel tubes in terms of corrosion resistance?

- Plastic tubes generally offer better corrosion resistance compared to stainless steel tubes. While stainless steel is known for its durability and resistance to corrosion, it can still be affected by certain chemicals and environments. On the other hand, plastic tubes, particularly those made from materials like PVC or PTFE, are highly resistant to corrosion, making them a preferred choice in applications where corrosive substances or environments are present.

- Q: Are plastic tubes suitable for use with hot liquids?

- No, plastic tubes are generally not suitable for use with hot liquids as they can melt or release harmful chemicals when exposed to high temperatures.

- Q: me and my father were trying to fix a leaf blower(the cord you have to pull will come out but won't go in) and ran into a few problems. we had to pull the whole thing apart to get to it, and along with pulling everything off we had to take off the switches that handle choke and run, and the tubes connected to this device were corroded from gas left in the leaf blower. where can i buy this tubing, and some sealant for the tubes? i DO NOT want a website that i can order them from, i want an ACTUAL store in the Dallas fort worth area.

- a place that repairs these or lawn eq. would probably have it. Thats were I've gotten similar parts

- Q: How to change the upper WATER plastic tube, inside the door, Kenmore side by side frige mod 596.57542791.?

- Not quite sure which hose that you mean. In between the outer shell and the door liner? Or in the dispenser housing itself. But check these out maybe it will help you out. Good Luck

- Q: Looking for some type of plastic tube with an internal measurement of about 15mm and around 130mm to 150mm in overall length. Needs to be solid one end and some type of removable cap on other end. Looking for around 500+ pieces in total

- You need to give more detail. Rigid or flexible? Resistant to solvents? Does it have to bear any pressure? Thin walled or thick? UV stable? Cap to be gas- or liquid-tight ? Does 'clear' mean not tinted or just transparent?

Send your message to us

Plastic Tubes - PPR Plastic Pipe China Professional Pipe Supplier in 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 ft

- Supply Capability:

- 10000 ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords