Plastic Sheets - PVC Free Foam Board & Polystyrene Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

PVC foam sheet is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm,as your required

Thickness:1-33mm

Density:0.35-0.9

3.Product Features

(1) Light weight, waterproof

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

(6)Fire retardant and self-extinguishing.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

(4)Screen printing, flat solvent printing, engraving, billboard and exhibition display.

(5)Chemical anti corrosion project, special cold project, environmental protection.

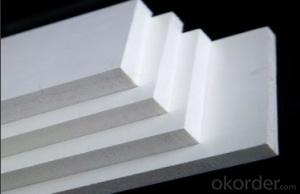

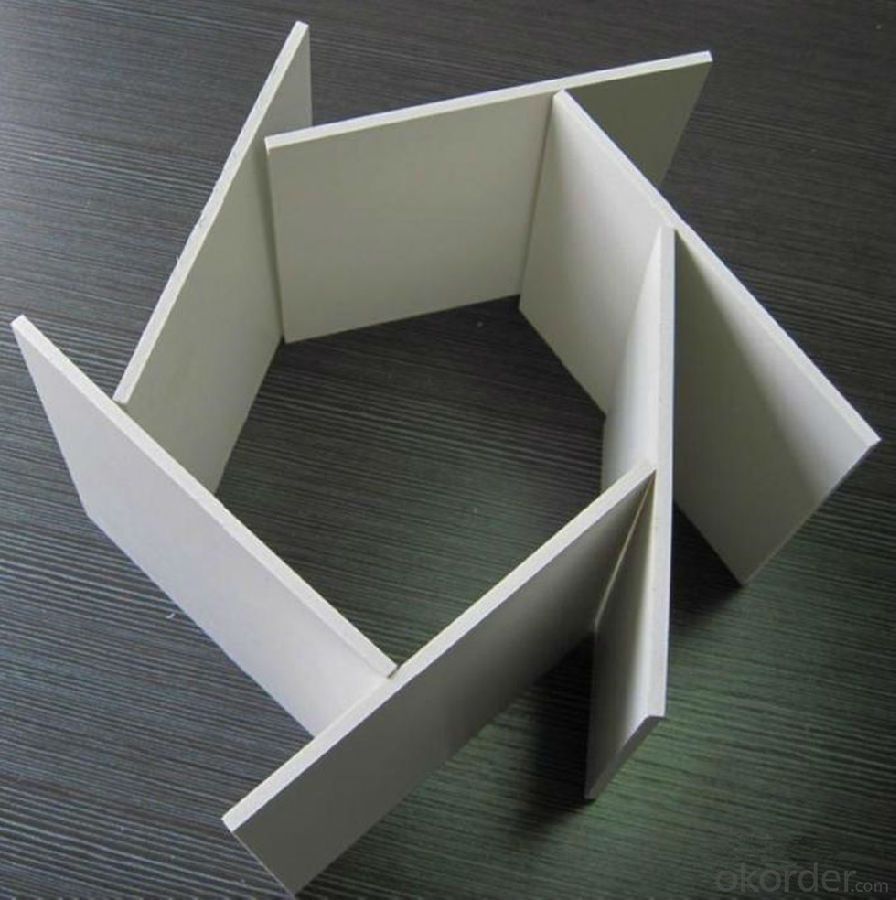

5. Pictures of PVC Foam Sheet

6.Pictures of Factory

7.FAQ

Q:What parameters should we offer us for proper quotation?

A:Application,Density,dimension,color,quantity,packing requirements.

Q: What are your payment terms?

A: T/T, L/C, West Union, etc.

- Q: I must be having a brain fart! I can't remember why I bought six rolls of duck tape and heavy gauge plastic sheeting. I remember that it had something to do with the Y2K scare but what the hell? Can someone refresh my memory, please?

- Water collector?

- Q: Can plastic sheets be cut to size?

- Yes, plastic sheets can be cut to size using various cutting tools such as saws, knives, or laser cutters.

- Q: In the home decoration inside, acrylic panels and ordinary plastic panels what is the difference?

- Acrylic is a transliteration of the word, "PMMA" is a chemical called polyacrylate, commonly known as "organic glass" after special treatment, in the raw materials industry in general application of acrylic particles, plates and pipes and other forms.

- Q: What are the temperature limits for plastic sheets?

- The temperature limits for plastic sheets vary depending on the type of plastic. However, most plastic sheets have a temperature range of around -40°C to 80°C (-40°F to 176°F).

- Q: What are the different surface treatments available for plastic sheets?

- There are several surface treatments available for plastic sheets, including: 1. Coating: Plastic sheets can be coated with various materials like acrylic or polyurethane to enhance their appearance, provide added protection against scratches, and improve chemical resistance. 2. Laminating: Lamination involves applying a thin layer of plastic film onto the surface of the sheet, which can provide additional strength, durability, and resistance to moisture, UV radiation, and chemicals. 3. Printing: Plastic sheets can be printed with designs, logos, or patterns using techniques like screen printing, digital printing, or offset printing, allowing for customization and branding opportunities. 4. Embossing: This treatment creates a textured or raised pattern on the surface of the plastic sheet, adding a tactile dimension and aesthetic appeal. 5. Etching: Etching involves chemically or mechanically altering the surface of the plastic sheet to create a matte or frosted appearance, reducing glare and improving light diffusion. 6. Varnishing: Applying a clear varnish to plastic sheets can provide a glossy finish, enhancing the visual appeal and protecting the surface from scratches and abrasion. These surface treatments offer a range of benefits, allowing plastic sheets to meet specific functional and aesthetic requirements in various industries such as automotive, packaging, construction, and signage.

- Q: milk bottle, shampoo bottles. i was thinking cut them open, melt them with a heat gun and roll them flat then how do i bond them into a big sheet?

- Not really Physics. Try asking under Engineering.

- Q: You know how dvd cases are made of somewhat flexible plastic? Where can you find sheets of those? (if you even can)

- Michael's Crafts ;)))

- Q: What are the common kinds of plastic sheets?

- Benefit home formaldehyde free health board. Whether the board is good or not depends mainly on the environmental protection grade.

- Q: Can plastic sheets be used for outdoor furniture?

- Yes, plastic sheets can be used for outdoor furniture. They are durable, weather-resistant, and low-maintenance, making them suitable for outdoor use. Additionally, plastic sheets can be easily shaped and molded, allowing for various designs and styles in outdoor furniture.

- Q: Introduce a kind of super light and super hard board

- Foshan, Kyrgyzstan osaka. Years of wardrobe design customization experience. Sliding door wardrobe, sliding door wardrobe, a variety of styles. It is customized according to the customer's idea, and the customer is the designer

Send your message to us

Plastic Sheets - PVC Free Foam Board & Polystyrene Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords