Plastic Sheets - Plastic Printing PVC Foam Board Sign/PVC Forex Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Introduction

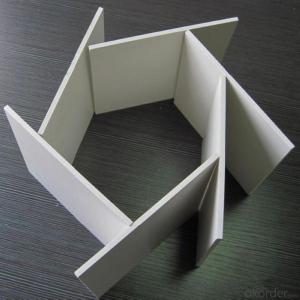

PVC Foam Sheet, a kind of high-tech product, is produced by special machinery and technology processing. The main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as glossy or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

Kingstar PVC Foam sheet is manufactured by the equipment imported from well-known Italian Bausano Group and Austria Cincinnati Company. We, with more than 15 years' processing experience, have invented several formulas to ensure every piece of sheet could be perfectly used.

2. Product Specifications:

Specifications: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness: 1-33mm

Density:0.43-0.9g/cm3

Color: Mainly white, Black,as required

3 .Product usage:

1.Light weight, easy and convenient to storage, transportation and use

2. It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

3. Uniform fine & close cell structure

4. Hygienic, Rigidity, Durable

5. Perfect chemical corrosion resistance, good resistance to UV & weathering

6. Fire retardant and self extinguishing

7. Moisture-resistant, mildew proof, rot proof, low water absorption

8. Non-deformation, color fastness for a very long time

9. Sound insulation, sound absorption, heat insulation and heat preservation

10. Easily to put protective film on one or two sides

11. Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

4.PVC foam board part of the end product icon:

5 .product features and advantages

A. The characteristics of waterproof, flame retardant, acid and alkali, mothproof, lightweight, heat insulation, sound insulation and damping.

B. and the same processing of wood, and processing performance is far superior to wood

C. is an ideal substitute for wood, aluminum and composite plates.

D. skin plate surface is very smooth, high hardness, not easy to have scratches, commonly used in the production of cabinets, furniture, etc.

6.PVC foam board market prospect:

PVC foam has many advantages, the application of a very wide range, at present in developed countries has been a very wide range of applications, and the development of more slowly in china. With the country's energy saving and environmental protection requirements of building materials and other materials and the increasing scarcity of wood resources in China, PVC foam board will usher in rapid development.

7. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

8. FAQ:

(1)What is PVC board?

the implementation of GB/T4454-1996 quality, good chemical stability, corrosion resistance, high hardness, high strength, high strength, anti UV (aging), fireproof (self extinguishing), reliable insulation performance, smooth surface, no water, no deformation, easy processing etc.. This product is excellent heat molding material, can replace part of the corrosion resistance of stainless steel and other synthetic materials, and is widely used in petroleum, chemical industry, electroplating, water purification equipment, environmental protection equipment, and mining, medicine, electronics, communications and decoration industries.

(2)Main product specifications

Size: 1220*2440mm (about 70% of sales),

1560*3050mm (about 20% of sales),

2050*3050mm (about 10% of sales)

Main product thickness:1mm,2mm,3mm,5mm,8mm,10mm,12mm,15mm

- Q: my doubt is that if the plastic used for recycling may be any medical things such as blood bags,cyringe(used for injuction,etc) the viruses from that material goes alive in the new material made frm recycled plastic?

- It sounds like you have a fear of germs/virus'. I cannot say that I know for fact, but I'm pretty sure that in the process of recycling products they are melted down at extremely high temperatures. Temperatures high enough to kill off all bacteria, before they are then re-assembled into the various products we use today. Also, it is highly unlikely that things such as syringes and bags containing blood and other human liquids ARE recycled. Those things are considered Hazardous Waste and are placed in specifically designed sealed waste bins, and disposed of safely. It would be incredibly irresponsible for a hospital to recycle such products, as you've suggested, and it would also leave them open to millions of lawsuits! Can you imagine? I am sure that the plastic bags you see have been recycled from other plastics such as.. bags, pop bottles, laundry detergent bottles and the like..

- Q: Are plastic sheets resistant to warping due to temperature changes?

- Yes, plastic sheets are generally resistant to warping due to temperature changes. However, the degree of resistance may vary depending on the type and quality of the plastic used.

- Q: hi everyone. making an outdoor sign for a school art/craft fair. have a plastic sheet with a nutcracker on it. want to adhere it to some plywood but dont want it to rip in the weather/ wind. i tried gorilla glue but it worked only so so. any good ideas are appreciatedthanks all

- Liquid nails is a colored caulk and if the plastic sheeting is transparent or translucent then you would see the liquid nails through it. Get contact cement. apply to both surfaces and let dry to the touch then apply them together. Make sure you are squared up because once it touches you won't move it. not sure if it is avail. in a spray. Make sure you get the clear contact cement some has a yellow tint to it when it dries. Hope this helps!

- Q: how do we make a transparent plastic sheet translucent?or vice versa

- Rub the transparent sheet with fine sandpaper. Vice versa - polish it with successively finer grades of polish.

- Q: What are we up to?

- You are going to re-create an oil spill, as an experiment...

- Q: i am using it to glue to the bottom on a skimboard so it rides smoother on the water

- I don't know if a plastic sheet would hold up to the pounding it would take. Maybe try an epoxy coating such as used on garage floors. Easy to apply, slick and smooth, very tough, and easy to repair if damaged.

- Q: Can plastic sheets be painted?

- Yes, plastic sheets can be painted. However, it is important to choose the right type of paint that adheres well to plastic surfaces and to properly prepare the plastic before painting to ensure good adhesion.

- Q: the plastic should be plain without any writting at all.

- Maybe at a hardware store or a building supply store. They may have some pieces, similar to plexiglass but thinner.

- Q: Are plastic sheets resistant to discoloration from cleaning agents?

- Yes, plastic sheets are generally resistant to discoloration caused by cleaning agents.

- Q: I need just a few sheets of ABS plastic sheet, about 12X50is there anywhere that sells this for under $50?

- You can buy a huge amount of plastic sheeting for very little money at any building supply place there is. Sometimes they sell it in precut rolls, sometimes you can buy it by the foot, especially in the heavier grades which will be more suitable for building something out of. That kind of plastic isn't clear, though, it's kind of cloudy to look through. You might want to check out clear vinyl at a fabric store. They sell that for using as tablecloths, and you can buy as little as half a yard. If you want to see the snakes easily, that might be a good choice for the front. It's pretty tough. If you want or need tape that will stick nicely to plastic, look for the red plastic tape used for vapour barrier in a house. It's not cheap and it's not pretty, but it's about the only tape that will really really stick to plastic. Pretty much all the others will eventually let go. Another possibility for something easy to see through is the stuff they sell for putting on windows to insulate them. It goes on with sticky stuff along the edges, the plastic gets stuck to it, then you shrink it tight with a hairdryer. It's extremely clear, tougher than it looks, you can stab it with a finger and it should be fine, but it will puncture with anything sharp. Cat's claws, for instance, did mine in when the cat swiped at a moth. You also have to be sure that you have a good clean smooth surface for the sticky stuff, or it will pull away as the plastic shrinks with the heat.

Send your message to us

Plastic Sheets - Plastic Printing PVC Foam Board Sign/PVC Forex Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords