Plastic Sheets - Lightweight PVC Foam Sheet Printing for Outdoor Boards

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed

pecifiation of PVC foam board can be produced by our PVC foam board machine:

Width: 915mm to 1830mm

Thicness: 1-33mm

Density: 0.45-0.9g/cm3

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Production flow of PVC/WPC foam board:

Material batching mixing_extruding_molding_vacuum calibrating and cooling_hauling_cutting- final WPC foam boards

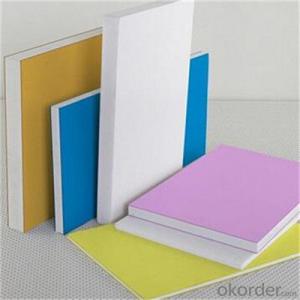

Popular Surface treating ways:

- lamination

- hot stamp printing

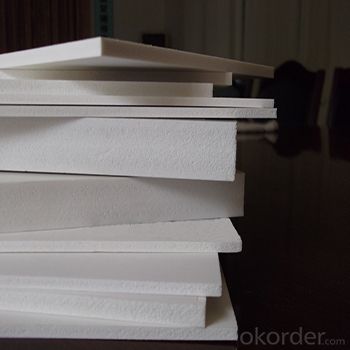

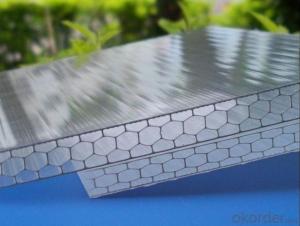

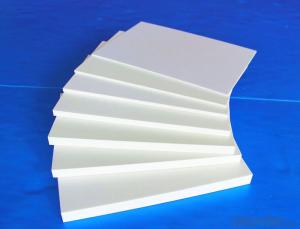

photos:

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance before shipme

- Q: Can plastic sheets be used for packaging fragile items?

- Yes, plastic sheets can be used for packaging fragile items. They provide a protective barrier and can cushion the items, preventing breakage or damage during transportation.

- Q: Can plastic sheets be used for costume making?

- Yes, plastic sheets can be used for costume making. They are often used to create various costume elements such as armor, masks, or unique accessories. Plastic sheets offer versatility, durability, and can be easily shaped and customized to achieve desired costume designs.

- Q: suggest two ways of converting transparent plastic sheet into translucent sheet

- Rubbing with something rough like sandpaper or etching with a fairly strong acid perhaps or even painting with something opaque?

- Q: Can some one please tell what is used as glue to fix plastic sheets ?

- buy an epoxy glue or a plastic steel glue. You can get them at walmarts or any autoparts store.

- Q: Are plastic sheets eco-friendly?

- Plastic sheets are generally not considered eco-friendly due to their production process, non-biodegradable nature, and contribution to pollution and waste.

- Q: A sheet of plastic, n = 1.5, 25 mm thick is used in a bank teller's window. A ray of light strikes the sheet at an angle of 45°. The ray leaves the sheet at 45° but at a different location. Use a ray diagram to find the distance between the ray that leaves and the one that would have left if the plastic were not there. mm

- David, your answer is incorrect according to the webassign. I'd done exactly that,

- Q: Can plastic sheets be used for room divider partitions?

- Yes, plastic sheets can be used for room divider partitions. They are lightweight, cost-effective, and easy to install. Plastic sheets offer privacy and can help separate spaces while allowing light to pass through. They come in various colors and designs, making them a versatile option for room dividers.

- Q: those plastic sheets that can be usd in picture frames, on the shed or in the house, I have seen them in BQ, what shall i type when searching for the plastic sheet on 'OKorder', I have typed plastic sheets but no luck, can you help me on this one.

- For a rigid sheet they're typically polymethylmethacrylate (PMMA) or the trade name Lexan. PMMA is cheaper than polycarbonate.

- Q: What are the different surface treatments available for plastic sheets?

- There are several surface treatments available for plastic sheets, including: 1. Coating: Plastic sheets can be coated with various materials like acrylic or polyurethane to enhance their appearance, provide added protection against scratches, and improve chemical resistance. 2. Laminating: Lamination involves applying a thin layer of plastic film onto the surface of the sheet, which can provide additional strength, durability, and resistance to moisture, UV radiation, and chemicals. 3. Printing: Plastic sheets can be printed with designs, logos, or patterns using techniques like screen printing, digital printing, or offset printing, allowing for customization and branding opportunities. 4. Embossing: This treatment creates a textured or raised pattern on the surface of the plastic sheet, adding a tactile dimension and aesthetic appeal. 5. Etching: Etching involves chemically or mechanically altering the surface of the plastic sheet to create a matte or frosted appearance, reducing glare and improving light diffusion. 6. Varnishing: Applying a clear varnish to plastic sheets can provide a glossy finish, enhancing the visual appeal and protecting the surface from scratches and abrasion. These surface treatments offer a range of benefits, allowing plastic sheets to meet specific functional and aesthetic requirements in various industries such as automotive, packaging, construction, and signage.

- Q: What are the weight limitations of plastic sheets?

- The weight limitations of plastic sheets can vary depending on the type and thickness of the plastic. Generally, plastic sheets can support lighter loads, such as a few pounds, but may not be suitable for heavy objects or significant weight-bearing applications. It is important to consider the specific properties and specifications of the plastic sheet to determine its weight limitations accurately.

Send your message to us

Plastic Sheets - Lightweight PVC Foam Sheet Printing for Outdoor Boards

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords