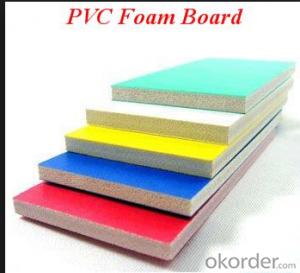

Plastic Sheets - Decorative Anti-Corrosion PVC Foam Sheets for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

Usage Life | more than 50 years |

Hardness | ≥10Mpa |

Elongation at Break | ≥10% |

Water Absorption | ≤1.0% |

Application | Wall cladding, decorating shelf, etc |

Marked uniqueness:

1. Lighter weight, better tenacity, and higher rigidity

2. Fireproof, waterproof, mould proof, sound proof, and flame retardant

3. Better insulation, thermal insulation,

4. No sopping, no deformation

5. Easier to clean and process

6. Better plasticity, super thermoform material

7. Sub-light surface and elegant vision

8. Anti-chemical corrosion

9. Suitable to silk screen printing

10. with imported dyes, unfading and anti-aging

12. Higher surface hardness and lighter texture

13. Optimal substitution for wooden boards in furniture industry

14. be able to cut, saw, weld, glue, thermal forming, nail, plane, caving forming.

15. Uniform foam holes, non-toxic and odorless, smoother surface and brilliant colors.

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

- Q: How do plastic sheets handle extreme weather conditions?

- Plastic sheets are designed to be durable and resistant to extreme weather conditions. They can withstand high temperatures, heavy rain, strong winds, and even snow. However, prolonged exposure to extreme weather can cause some degradation over time, such as fading or brittleness. To ensure their longevity, it is important to choose high-quality plastic sheets and provide proper maintenance and protection, such as regular cleaning and UV-resistant coatings.

- Q: Are plastic sheets resistant to impact from hail?

- Yes, plastic sheets are generally resistant to impact from hail due to their flexibility and durability. However, the level of resistance may vary depending on the thickness and quality of the plastic used.

- Q: A victim of an automobile accident was lying in pain by the side of the road with a thoracic wound which was making a strange sucking noise with each labored inhalation. A passing off-duty paramedic applied a moist plastic sheet to the wound and the sound stopped. Why was the patient in pain? What would eventually have happened to the lung on the injured side if no care had been administered? Why was it important that the plastic sheet be moist?

- You need to do your own homework. Read the chapter on thoracic trauma and figure it out. When you get out into the field no one will be there to spoonfeed you and hold your hand. This is pretty basic stuff.

- Q: Can plastic sheets be printed on?

- Yes, plastic sheets can be printed on.

- Q: I need a small sheet of transparent plastic (is perspex what I am looking for or is this only a single variation?) about 1m x 0.25m (and only a few of mm thick)I can only find it on the internet in vast quantaties!!Thanks!

- A okorder / if you live near one of their warehouses they might cut and sell you an offcut cheap.

- Q: Do plastic sheets have any impact on chemical resistance?

- Yes, plastic sheets can have an impact on chemical resistance. The type of plastic used in the sheet can determine its ability to withstand various chemicals. Some plastics are highly resistant to certain chemicals, while others may react and degrade in the presence of certain substances. It is important to consider the chemical compatibility of the plastic sheet when choosing the appropriate material for specific applications.

- Q: Can plastic sheets be used for DIY sneeze guards?

- Yes, plastic sheets can be used for DIY sneeze guards.

- Q: How do plastic sheets compare to PETG sheets?

- Plastic sheets are a broad category that includes various types of materials, while PETG sheets specifically refer to sheets made of polyethylene terephthalate glycol-modified plastic. In comparison, PETG sheets offer superior clarity, impact resistance, and chemical resistance compared to many other plastic sheet options. They are highly durable, lightweight, and can withstand a wide range of temperatures. Additionally, PETG sheets are often chosen for their ease of fabrication, recyclability, and FDA compliance, making them a popular choice for applications such as signage, displays, packaging, and medical equipment.

- Q: Can plastic sheets be used for machine guards?

- Yes, plastic sheets can be used for machine guards. Plastic sheets are often used as a cost-effective and versatile option for machine guards. They offer good impact resistance, visibility, and can be customized to fit specific machine requirements. Additionally, plastic sheets are lightweight and easy to install, making them a popular choice for many industrial applications.

- Q: What are the installation methods for plastic sheets?

- There are several installation methods for plastic sheets, including using adhesive, mechanical fasteners, or heat welding. Adhesive installation involves applying a specialized adhesive to the back of the sheet and then pressing it onto the desired surface. Mechanical fasteners such as screws or clips can be used to attach the sheets to a substrate. Heat welding, on the other hand, involves using a hot air gun or a welding machine to melt the edges of the plastic sheets and fuse them together or to a surface. The choice of installation method depends on the specific application and the type of plastic being used.

Send your message to us

Plastic Sheets - Decorative Anti-Corrosion PVC Foam Sheets for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords