Plastic Sheets - Corrosion-Resistant High-Grade Decoration Materials PVC Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

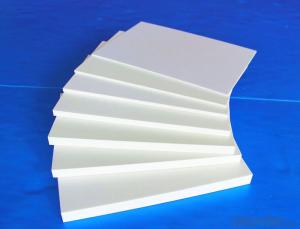

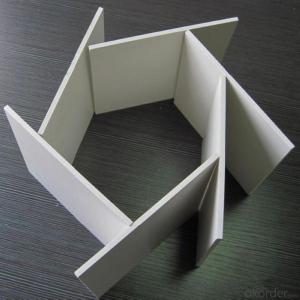

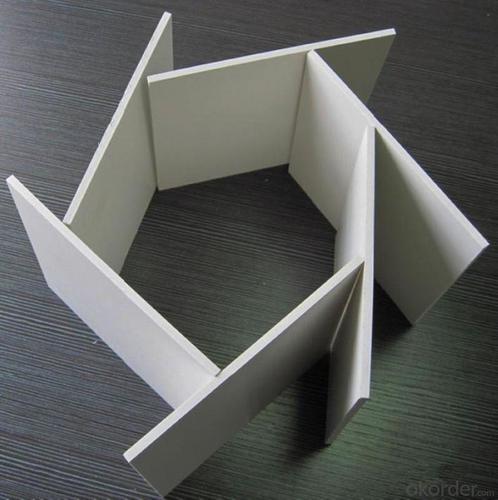

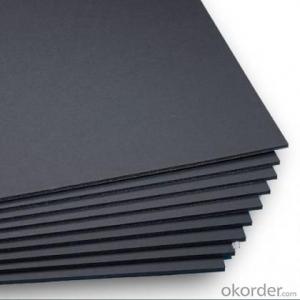

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

Product Application

Application fields | The specific application |

Household furniture | tables , chairs , benches , stools – furniture, Sofa, Box spring, Bookshelf, clothing case, tea table, screen, frame, handle, plate, bar, newspaper rack. |

Construction | Mobile home, window frame, door plank, threshold, template, concrete stairs clap, wallboard, ceiling, floor, and various profiles, etc |

Industrials | Chemical corrosion barrack and public places, decorating plate, floor, channel, bench, and the casting model, the machine cover, pump shell, electrical materials, etc |

........ | |

PVC foam board market prospect

PVC foam has many advantages, the application of a very wide range, at present in developed countries has been a very wide range of applications, and the development of more slowly in china. With the country's energy saving and environmental protection requirements of building materials and other materials and the increasing scarcity of wood resources in China, PVC foam board will usher in rapid development.

pictures

- Q: What are the common applications of plastic sheets?

- Plastic sheets have a wide range of common applications, including packaging materials, construction materials, automotive components, signage, electrical insulation, greenhouse coverings, and various DIY projects.

- Q: What is the difference between ABS plate and HIPS plate?

- No, it's just that ABS has better resistance to chemicals, weather resistance, cold resistance and mechanical properties than HIPS

- Q: I want to make my own slip and slide tomorrow and i am going to use some plastic drop sheets.But i need to find a shop to get it for tomorrow. Anyone know of large retail shops that sell them? Thanks

- difficult problem. query at a search engine. that will can assist!

- Q: well i was just at this weird consert and there was a plastics thingy so im just wondering

- The percussion sound will deafen you...you'll notice that it is easier on the ears when the sound is behind barriers.

- Q: Do plastic sheets have any odor?

- Yes, plastic sheets can have a mild odor, particularly if they are made from certain types of plastic or contain chemicals. However, the odor is usually minimal and dissipates over time or with proper ventilation.

- Q: Are plastic sheets resistant to impact?

- Yes, plastic sheets are generally resistant to impact due to their inherent flexibility and durability.

- Q: I have an 08 Hyperlite Era board that has a big problem. the top plastic sheet is peeling off at the edges and it is dragging in the water bad. i dont want to buy a new board but i cant fix it. I have already tried a permanent epoxy-resin but it was destroyed after the first use. I am now thinking of shrink wrapping a resin type plastic onto the whole edge but i dont know what i am doing. Does anybody have any suggestions?

- Try going back to epoxy and try again. This time prep the surfaces by sanding with a fairly fine sand paper, and make sure all surfaces are dry. If you attempt to epoxy to either a too smooth surface, a water wetted surface or a surface that has another wax or adhesive on it the epoxy won't adhere properly. Clean and sand the surfaces first and the epoxy should be stronger than new. Good luck with your repair..

- Q: Have seen many bands perform with their drummers in plastic boxes. Especially rock bands.

- i don't know, but that seems weird...

- Q: Thanks you guys! You're always so smart!

- You could get a row of 16 across the sheet, and you could get 96 rows like that one. Now you calculate how many that would be.

- Q: Do I use 2x6? 2x4?. ????????

- Well I have been a carpenter all of my adult life and I am 76 now and retired. (tired to) To start with I would use a product called DRY-LOCK on your concrete walls, Next I would put a border of 1X4s top, bottom, and ends, installed useing toggle bolts with flat heads so you can counter-sink the head of the bolt 3/16 inch bolts is enough the length being determined by the thickness of the congrete block + 1/2 inch sheetrock + allow about 1 inch, My guess is about 3 1/2 to 4 inches long.Then put in your studs, useing 1X4s 16 inchs on center. The bolts only need to be about 36 inches apart. Make sure you measure correct and that you center your sheetrock at the end of each sheet. use 1inch or 1 1/8 inch drywall screws. your not going to support a house your only going to support the sheetrock, Don't forget to do your wireing? and they make elect. boxes for just that thickness. Have some in my basement, Unless your in a hurry, you can work as hard or as slow as you want, you have a cover over your head. Also I would plan on putting in a drop ceiling, it covers up a lot of overhead stuff, and gives your Electric wires a place to run. Good Luck

Send your message to us

Plastic Sheets - Corrosion-Resistant High-Grade Decoration Materials PVC Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords