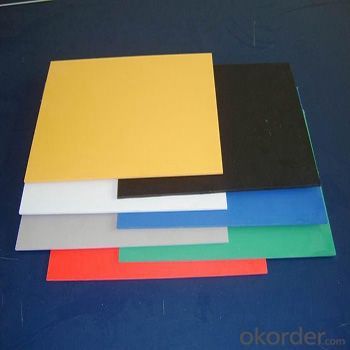

Plastic Sheets - 4x8 High Quality and Inexpensive PVC Forex Closed-Cell Foam Board Wall Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Detailed specifications:

Thickness 1-33mm

Width 1220mm, 1560mm, 2050mm

Length As requirement

Color: white,black etc.

We also can manufacture according to your requirement.

Advantage:

1. Waterproof, Moisture/Water resistant, less rotten, proven under salt water condition, UV-resistance

2. Fire retardant and self-extinguishing

3. Sound-insulated; Non-toxic

4. High recyclable, eco-friendly, saving forest resources

5. Weather resistant, suitable from minus -30 to 70 centigrade degree

6. Well done of Termites, insects, and moldy-proof

7. Easy to nail, hammered, drilled, sawed, turned, glued, bended, printed, oiled, thermoforming

8. Easy to clean

9. No any benzene and the formaldehyde discharge,Non-toxic

Here you can choose:

1. Size:

1220*2440mm(4*8foot)

1560*3050mm, 2050mm*3050mm

2. Color:

white,black,green,blue,yellow ,orange and more than 100 kinds of color

3. Thickness:

1-30mm is available

4. Density:

0.4-0.8g/cm3

- Q: Can plastic sheets be used for bathroom walls?

- Yes, plastic sheets can be used for bathroom walls. They are a cost-effective and waterproof option that is easy to install and maintain.

- Q: filled bubbles. the lenses in these sheets are advertised to focus heat from the sun into the water and raise its temperature. do you think the lenses of such sheets do in fact direct more solar energy into the water?

- If anything less solar energy is getting to the water as some of the energy will be wasted heating the cover itself. However the cover will keep in the heat of the pool as it is heated, so it does work, just not the way it's advertised to.

- Q: What are the load-bearing capabilities of plastic sheets?

- The load-bearing capabilities of plastic sheets vary depending on the type of plastic and its thickness. Generally, plastic sheets have a good strength-to-weight ratio and can support moderate loads. However, they are not as strong as materials like metal or wood and may deform or break under excessive weight or pressure. It is important to consider the specific plastic material and its specifications to determine its load-bearing capabilities accurately.

- Q: I mean the sheet that is used to make control panels its normally black and when etched it shows white, do any companies offer a custom service who sells it whats the term for this

- a b s plastic?

- Q: Are plastic sheets resistant to bending under weight?

- Yes, plastic sheets are generally resistant to bending under weight.

- Q: Are plastic sheets resistant to abrasion?

- Yes, plastic sheets are generally resistant to abrasion.

- Q: Hi All,(sorry if this is in the wrong category, I couldn't find appropriate)I'm trying to bind a book, preferably on my own without going to kinkos or wherever. But the sheets are not regular sheets of paper but overhead sheets (plastic sheets.) I want it to look clean like a real book, but because they are overhead sheets, I'm worried that they might fall apart or be too bulky. I was thinking glue, as in hot glue because I can't find anywhere that does hot press - I'm in Toronto.Does anyone have any suggestions? I was going to sew them, but the paper is, again, too thick.

- sewing may work if you pre-punch the holes with a hole puncher

- Q: Plastic buckle ceiling artificial costs how much a square meter?

- PVC plastic gusset plate, PVC raw material, adding quantitative modifier, modifier and other additives by mixing, calendering, vacuum blister technology, applicable to the kitchen, Wei hung ceiling decoration, the current home, kitchen, Wei and other ceiling materials

- Q: Can plants grow well under 4 millimeter plastic sheeting.?

- Yes but what ever you do make sure the sheeting does not touch the plant. In winter it can cause frost damage and in summer can burn the plants.

- Q: Can plastic sheets be used for hygienic applications?

- Yes, plastic sheets can be used for hygienic applications. They are commonly used in healthcare settings, food processing industries, and cleanrooms due to their ability to create a barrier against contaminants, ease of cleaning, and resistance to moisture and chemicals. Plastic sheets can be sanitized easily and are often used as protective covers, barriers, or liners to maintain cleanliness and hygiene.

Send your message to us

Plastic Sheets - 4x8 High Quality and Inexpensive PVC Forex Closed-Cell Foam Board Wall Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords