Waste Plastic Recycling Washing Machine

- Loading Port:

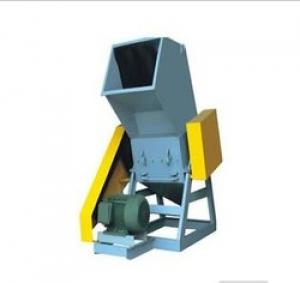

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set pc

- Supply Capability:

- 20 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

wast plastic recycling washing macine

1.100 -2000 Kg /h

2.label removing,crushing, washing,drying

3.CE certification

4.OEM

wast plastic recycling washing machine

The line contains the equipment of

(1)belt conveyor,

(2)crusher,

(3)PVC label-remover,

(4)screw conveyor (2sets),

(5)boiler,

(6)horizontal washer,

(7)single-screw floating washer,

(8)dewatering machine,

(9)dry storage hopper,

(10)electrical control box.

1. Belt conveyer

Transporter with frequency control, to adjust speed to requirements of line.

2. Crusher

This crusher is designed for wet crushing. It is equipped with eight rotating and four stationery knives. Crusher is supplied with standard grid size of 16mm and spare grid of 18mm. Input capacity is 1, 000kg/h can be increased with 18mm grid size.

3. Screw conveyer

Transport flakes from crusher.

4. Floating washing tank(3-4 sets)

Flotation/sink tank separate the material according their density. PET sinks to the bottom and is discharged by a screw conveyor. Remains of caps and rings made of PE and labels of PP floats on the top and are moved by rotating shovels to side of washing tank. Small screw conveyor take them out. This machine removes 90% of paper and plastic labels.

5. Friction washing tank

The flakes are efficiently cleaned inside inclining drum with blades on rotor turn

wash and recycle waste PET bottle flakes. Waste and dirty PET bottle flakes can be treated step by step by this facility. It is special for washing PET bottles flakes. We can help to attach equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after being washed.

The whole production line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products.

Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PET bottles to be the PET granule material and in order to producing new PET bottles.

After the this PET bottle flakes crushing, recycling and washing production line, our company also offer the following production lines of PET bottle granulating and injection, etc to make the waste and dirty PET bottle be the new finished products.

- Q: How many kinds of raw materials are produced by wrapping plastic film?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.Commonly used to bundle packaging is LLDPE stretch wrap film, applicable to a variety of logistics packaging, packaging industry bundled! I can see it in Ming Bao. Yes, please!

- Q: What are the raw materials of foam plastics and how do they come out?

- Chemical blowing agents are mainly azo organic compounds such as azo two formamide (ADCA or AC), 2, 2 '- azo two, DAB, AIBN, etc.. This kind of foaming agent is cheap, and the products are non-toxic, odorless and colorless. In addition to sulfonylhydrazine, such as 4, 4 '- oxo benzene sulfonyl hydrazide (OBSH) etc.. Attention should be paid to the decomposition temperature. The properties of chemical foaming agents are as follows:Azo two formamide (AC, ADCA). Orange crystalline powder. A large amount of gas (N2, CO and a small amount of CO2) is decomposed at 120 DEG C, and the gas yield is 200 ~ 300mL/g in the standard state, which is an efficient foaming agent.

- Q: Pollution in the production of plastic raw materials from petroleum production

- Petroleum - intermediate - polymerization monomer - resin - plastic particles - plastic products, the process of the above, each will have pollutants!

- Q: Is the plastic with high melting index good?

- Its test method is: first let the plastic particles in a certain time (10 minutes), under certain temperature and pressure, melt into plastic fluid, and then through a diameter of 2.1mm tube g (grams) outflow. The greater the value, the better the processability of the plastic material, the worse the contrast.

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- EPS is a foaming agent that is used to make foam, which is the white foam that is packed in the TV and refrigerator.

- Q: What material is good for plastic bellows?

- In the next case, it is recommended to use PP (polypropylene) bellowsNo strong acid and high concentration of oxidant in the environment; in more than 80 degrees Celsius in the environment of soluble in benzene, toluene and other aromatic hydrocarbons and chlorinated hydrocarbons in oil absorption; for most stable, small amount of mineral oil and vegetable oil.Mainly used in the temperature range of -20 to 120 degrees Celsius environment; used in automobiles, motorcycles and other motor vehicle wire harness sheath; also used for household appliances, precision machine tools and other equipment wiring wire sheath.

- Q: What are the main biodegradable plastic bags made of?

- The degradable plastic bags made of polyethylene and starch, but this can only be degradable plastic plastic degradation into smaller chunks of plastic, plastic compositions did not completely disappear, so its degradation is limited.

- Q: What are the raw materials needed for producing plastic hair dryer shell and flashlight shell?

- PA nylon as a large amount of Engineering plastics. Widely used in machinery, electrical appliances, textile equipment, chemical equipment, aviation and other fields. Become an indispensable structural material in all walks of life, the main features are as follows:1. excellent mechanical properties. High mechanical strength and good toughness.2. excellent heat resistance. Such as nylon 46, high crystallinity Nylon high thermal deformation temperature, can be used at 150 degrees Celsius for a long time. PA66 after glass fiber reinforcement, its thermal deformation temperature above 250 degrees celsius.3. excellent electrical insulation performance. Nylon has high volume resistance and high breakdown resistance. It is an excellent insulating material for electrical and electrical equipment.4. self lubrication, good friction resistance. Nylon has a good self lubrication, small friction coefficient, so as to drive parts, long service life.5. excellent weather resistance.

- Q: What are the plastic raw materials for this purpose?

- Plastic classification, composition and characteristics, plastic is a widely used synthetic polymer materials, in our daily life, plastic products abound.

- Q: What are the bulk density, size and moisture content of the general plastic material?

- The bulk density has something to do with particle size. The larger the particle, the smaller the bulk density of the same composition. This is because the accumulation of material quality, material bulk density = space volume. The bulk density is pseudo density.

1. Manufacturer Overview

| Location | Suzhou, Jiangsu, China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia |

| Company Certifications | ISO 9001:2000; ce |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Waste Plastic Recycling Washing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set pc

- Supply Capability:

- 20 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords