Waster Plastic Recycling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set pc

- Supply Capability:

- 10 Sets Per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

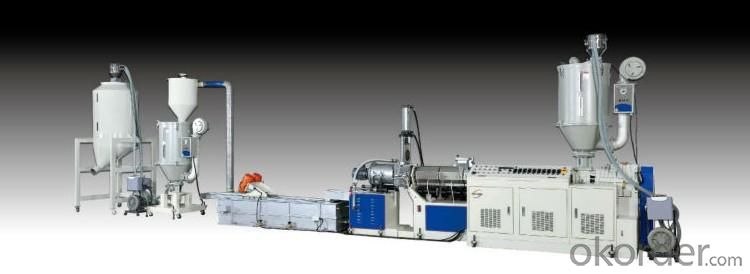

SJ-A wind-cooling Hot-cutting plastic Recycling Machine take HDPE,LDPE as the material,and make them into granules.

Name:SJ-A wind-cooling Hot-cutting plastic Recycling Machine

This raw materials like waste films of HDPE and LDPE are extruded through the extruder, and then are cooled through wind and cut hotly into granules, featuring in fine quality, bubble free and moisture free. The machine is equipped with a forced feeder, fast mesh changer and automatic rhermocontroller. Characteristics: Main Technical Variables

Main Technical Variables:

| Model | SJ-90 | SJ-100 | SJ-110 | SJ-120 |

| Type Diameter of Screw Stem | φ90 | φ100 | φ110 | φ120 |

| Major Diameter Ratio of Screw Stem (L/D) | L/D 201 -221 | L/D 201 -221 | L/D 201 -221 | L/D 201 -221 |

| Rational Speed of Screw Stem | 10-100r/min | 10-100r/min | 10-100r/min | 10-100r/min |

| Main Motor Power | 22kw | 30kw | 37kw | 45kw |

| Output | 68kg/h | 95kg/h | 120kg/h | 135kg/h |

| Weight of overall(kg) | 2600kg | 2800kg | 3000kg | 3200kg |

| Cover dimensions (l×w×h) (mm) | 4000×1500×1800 | 4000×1500×1800 | 4000×1500×1800 | 4600×1500×1800 |

- Q: Plastic PPT30S add what material will increase hardness?

- In general, this material will be grafted with PP-G, POE, increase the impact, plus stone powder, glass fiber, mica powder, increase hardness.

- Q: Plastic raw materials, why LDPE and LLDPE?

- LDPE is low density polyethylene, that is, high pressure material; LLDPE is linear material.

- Q: What is the concept of plastic raw materials for turnover containers?

- Suzhou Ke Reed plastic turnover box made of polypropylene, polyethylene synthesis, light weight, long service life, safety, non-toxic, tasteless, moisture-proof, corrosion resistance, light weight, durable, can be stacked, rich color, pure etc..

- Q: What is the essential difference between plastic raw materials and engineering plastics?

- Plastics can be divided into two major categories: General Plastics and engineering plastics. They are usually granular or powder in order to be easy to process before they are madeGeneral plastics refer to common plastics with large output, wide use, good formability and low price. Such as PVC, polyethylene, polypropylene, polystyrene and so on. Products made of plastic film, pipe, woven bags and plastic daily necessities. The yield and consumption of general-purpose plastics account for more than 80% of all plastics.Engineering plastics refer to plastics that meet the needs of industrial parts. Relatively speaking, they yield large, wide range of applications. Mainly ABS, polycarbonate, nylon, POM, modified polyphenylene ether, thermoplastic polyester and so on. Products have TV casing, plastic gears, optical materials, gaskets and so on.There is also a special engineering plastics, in addition to its characteristics of engineering plastics, its comprehensive performance is higher, long-term use temperature above 150 degrees celsius. It also has special functions and special uses. Mainly used in high-tech industries, such as atomic energy, rockets, satellites, aerospace, automotive, electronic and sports equipment, and other structural materials. Commonly used special engineering plastics are fluorine plastic, silicon resin, polyimide, peek, liquid crystal polymer and so on.

- Q: What is the specific material for plastic pallets?

- There are two kinds of raw materials for plastic pallets: one is polypropylene (PP) and the other is polyethylene (HDPE).Plastic pallets for logistics storage: pp+pe material, recycled material 10%;Plastic trays for food trays: food grade PP, PE, pc;

- Q: What raw material produces the plastic to the human body not to harm, to the environment does not have the pollution?

- For example, light degradable plastics manufacturing methods can be divided into light degradable plastics synthetic degradable plastics and adding degradable plastics. A, ethylene copolymer / carbon monoxide (E/CO) photodegradation to ketone backbone fracture characteristics of.E/CO light degradation speed and degree and the amount of the chain, the higher the content, the degradation rate of the soon, the greater. The United States of Texas, scientists have to E/CO for outdoor exposure experiments in sunny June, the fastest E/CO only a few days can be degraded. B, ethylene / vinyl ketone copolymer (Ecolyte) keto Ecolyte molecules on the side chain can be decomposed to.Ecolyte light the degradation performance is better than E/CO in the role of natural light, but the cost is higher. This kind of polymer drawback is once see the light starts to degrade, almost no induction period, need adding antioxidants to regulate the induction period Purpose. (2) add type light degradable plastics additive light degradable plastics with a small amount of photosensitizer in the polymer, at low concentration is the degradation of photocatalytic oxidation by solar irradiation (Zi Waiguang) and react to the polyolefin polymer fracture. In PE, PP polymers such as ketones, amines and adding photosensitizer can good photodegradability. Add light degradable plastics with low cost, simple production process, do mulching better. But the degradation characteristics of the exposure surface degradation more thoroughly, some less degradation buried in the soil. The degradation of this kind of photodegradable plastics can be controlled in the induction period of two months or more. But the degradation time control is poor.

- Q: ABS plastic storage conditions

- Plastic materials generally react with light and oxygen for a long time to become yellow and brittle

- Q: What are the raw materials for producing plastic films?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.

- Q: What is the raw material for producing high temperature polyethylene plastic bags?

- High density polyethylene (HIGH DENSITY, POLYETHYLENE, HDPE) commonly known as low-pressure polyethylene, compared with LDPE and LLDPE, with high temperature resistance, oil resistance, vapor permeability and resistance to environmental stress cracking resistance, and electrical insulation and shock resistance and cold resistance is very good, mainly used in blow molding, injection molding etc..

- Q: What do you mean by grade 1, class two or class three in plastic?

- Two material is that the raw material has been used once, but high pressure granulation except high-pressure granulation using imported large majority, if import large industrial film has not been exposed to the weather, so the quality is very good, the processed particles with good transparency, then it should be judged according to the brightness and surface whether the rough particles.

1. Manufacturer Overview

| Location | Zhejiang,China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | CE Certificate; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Waster Plastic Recycling Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set pc

- Supply Capability:

- 10 Sets Per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords