plastic formwork products-reusable plastic formworks for concrete

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

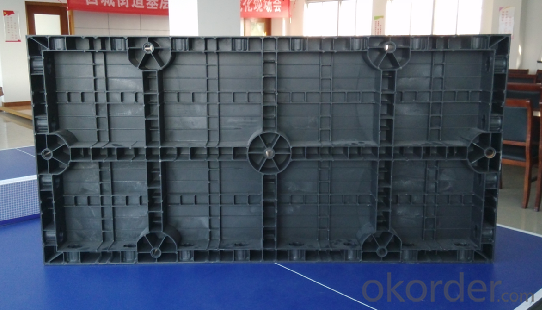

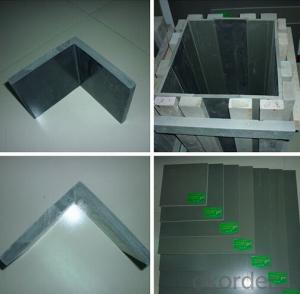

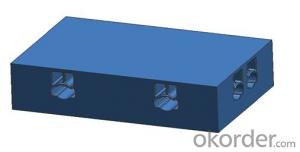

plastic formwork products-reusable plastic formworks for concrete

Saving your time, money and energy !!!

Features:

1. Long lifespan& Cost effective -- Plastic formwork can be reused over 100 times,

where Plywood can only be reused 3 to 5 times. Therefore the Plastic Formwork

is more cost effective.

2. Waterproof -- As the nature of plastic material. It's imputrescible and rustless,

especially suitable for underground and watery circumstance.

3. Interlocking Design -- No release agent needed, good effect of demolding.

4. Easy deassembly -- The template will be separated easily from concrete

5. Simple Installation -- Light weight and safe to handle, easy cleaning and very robust.

6. High Quality -- Abrasion resistance, excellent mechanical property, best impermeability.

7. Recycable -- Waste scrap molding board could be recycled.

Product Photos/ Plastic Formwork, Construction formwork, plastic concrete formwork

FAQ:

1.Q:Are you a factory or trading company?

A: We are a factory of plastic formwork.

2.Q:Where is your factory located? How can I visit there?

A: Our factory is located in Taizhou City, China.You can fly to Ningbo airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How can I get some samples?

A: We are honored to offer you samples.

4.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISOTS16949 authentication.

Why Choose us?

We are China Leading Moulding Manufactuer

Inspected by the Inspection Institution of Bureau Veritas Certification.

100% QC inspection Before Shipmeng.

Best Quality & Best Service with Competitive price.

How to Contact Us?

If you are interested in our plastic formwork , please feel free to contact with us by email. We will quote you the best price, if you have drawings, we can help you caculate the quantity of plastic formwork .

Any building drawings is OK, just send us your drawing, we can make the plastic formwork quantity for you.

And we warmly welcome friends from all over the world to visit our factories for business.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- You do not explain your product is to open a metal mold or plastic mold, the two mold materials are not the same! I do plastic mold, we mainly use the factory S136 quenching material as a mold material, the slider generally use 718. And you also have the output of the product requirements of the mold, the production will choose a better point of the material.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: Europe and the United States national construction template is made of plastic or wood

- Although the problem is not understand the landlord can not help.

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: Plastic mold dynamic template, the size of the template

- A lot of it? What are you talking about? Plastic mold points a lot of tonnage, there are 80T, 120T, 240T, 1000T, 1250T

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q: Plastic building template made of what material

- Template template, as the name implies, is a model (you can think so), and the building template is in the construction of the project, before making the actual product, according to the design pattern, according to the data, such as component dimensions and other related ghosts , To produce a model consistent with the design specifications, and the production of this model is the template material

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- You can do that kind of ah! Raw materials are not easy to find

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Over the past two years the domestic market has appeared several "plastic building template", many builders are also trying to use plastic building templates, we all recognize that plastic building template is to replace steel mold, wood mold, bamboo mold of the inevitable product, Is the future direction of the development of architectural templates. Now the country has six or seven plastic building template manufacturers. Production of plastic building templates are different materials, in order to help all the correct selection of builders, the market is now on the composition of several plastic building templates and performance for a rough analysis, to all the use of plastic building templates to build a wake up , To avoid blind selection and cause unnecessary losses.

Send your message to us

plastic formwork products-reusable plastic formworks for concrete

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords