Plastic Formwork Concrete Formwork Parts of Tubular Scaffolding Scaffolding Importers Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Formwork Concrete Formwork Parts Of A Tubular Scaffolding Scaffolding Importers Low Price

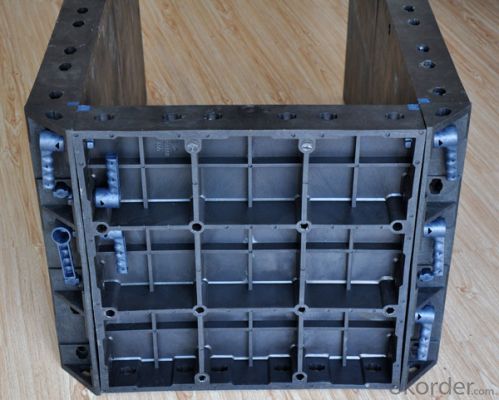

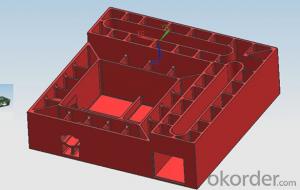

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

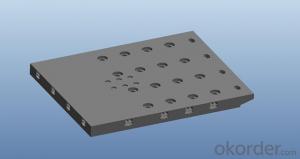

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

FAQ

We have organized several common questions for our clients, may help you sincerely:

1)How is the Packaging Details?

In bags or as the requirement ofcustomers.

2)How long can we receive the product after purchase?

Lead time is about 30days after getting the signed PI and deposit.

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- The lower the density of the foam board is easier to deform.Crust foam can be changed to coextrusion foam. General cross-linking or blending halogenation and other methods to improve Vicat. Reduce traction override

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- By our site identification: hollow plastic building templates to protect the case of the use of 50 times is not a problem, even more than 50 times. Not capped Plastic non-stick cement. You know.

- Q: Why the floor is not plastic building materials square wood and template

- Is the plastic strong? The environment on the site you know, throw off how to do, have to find strong and durable.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- The reason why the use of the template is to use the template template is the accuracy of the template, that is, after the mold can be set to ensure that the finished product finished shape regular, flush. While the plastic film version is not damaged, the completion can achieve this requirement. But the crux of the problem is that the biggest weakness of the plastic film is too brittle. Those who have done the work know that when the demolition of the template, the workers removed the template directly down to throw. And this throw to lead to the plastic film version of the broken, it is very difficult to film in the film. This is also the reason why the plastic film from the interview more than 10 years can not always develop the root causes. And then plastic film board in the mold when it is very strenuous, must drill with a drill, or can not die, not convenient construction. This is also a plastic film version can not become a mainstream template and a fatal weakness. The third weakness is its flammability. Construction site of the steel connections are required welding, welding flowers gradually to the plastic film board, at least in its surface to form a deep pit (or even lead to fire), a direct impact on the finished product surface finish and flatness.

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- The production of plastic building template not only has the many advantages of plastic template, but also successfully broke the plastic building template price is high, the price is equivalent to the current construction industry commonly used bamboo sheet, while giving the plastic template more advantage.

- Q: Types of building templates? What is the water template?

- Building a template, the use of rear surface roughness is better, do not need to deal with the second. Provincial workers, time-saving.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- The quality of the building template is relatively strong, compared to the cost is also higher. hope this helps!

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: Plastic building template where there is an urgent need to solve

- First, smooth and smooth. Temporarily stitching the stencil, the surface quality of the concrete structure after the demolding, the finish are more than the technical requirements of the existing water template, no need to plaster twice, the province of materials.

- Q: The price of raw materials can say better, is the PVC material.

- Templates in accordance with the different prices of materials are also very different. The general plywood is 50-65 / sheet.

Send your message to us

Plastic Formwork Concrete Formwork Parts of Tubular Scaffolding Scaffolding Importers Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords