PE PVDF aluminium composite panel exterior cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

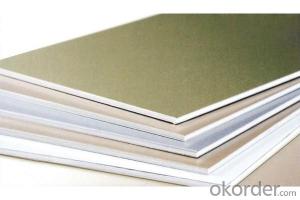

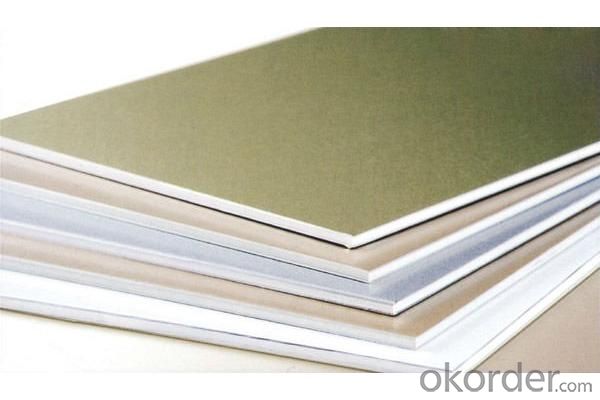

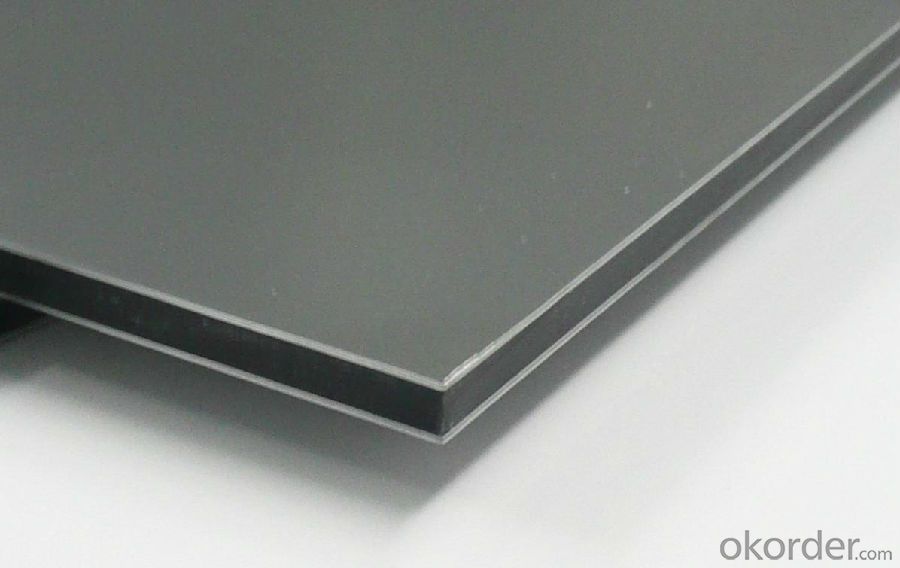

PE PVDF aluminium composite panel exterior cladding

| PRODUCT PARAMETER | |||||

| Product name | Pvdf Aluminum Composite Panel | ||||

| Material | Aluminum sheet and PE | ||||

| Brand name | Kaysdy | ||||

| Standard size | 1220mm x 2440mm x 3mm, 1220mm x 2440mm x 4mm | ||||

| Optional size | panel thickness | 3mm - 5.8mm | |||

| aluminum skin thickness | 0.08mm, 0.10mm, 0.12mm, 0.15mm, 0.18mm, 0.21mm, 0.25mm, 0.30mm, 0.35mm, 0.40mm, 0.45mm, 0.50mm | ||||

| panel width | 0.9m - 1.57m | ||||

| 0.9m - 1.57m | |||||

| panel Length | 5.8m is the best choice for container, or according to customized | ||||

| Core layer | Common PE or fireproof PE | ||||

| Surface coating | Polyester(PE) or Fluorocarbon(PVDF) | ||||

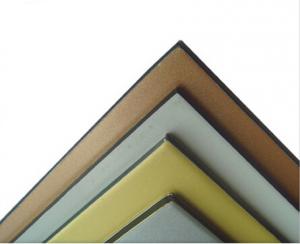

| Special treatment | Brushed, mirror, marble pattern, etc | ||||

| Features | 1. Excellent weather resistance | ||||

| 2. Outstanding characteristics of fireproof | |||||

| 3. High peel strength | |||||

| 4. Multiple colors | |||||

| 5. Easy and rapid installation | |||||

| 6. Environment friendly and Recycle | |||||

| 7. Perfect rigidity | |||||

| 8. Cleanness Maintenance | |||||

Pvdf Aluminum Composite Panel Material

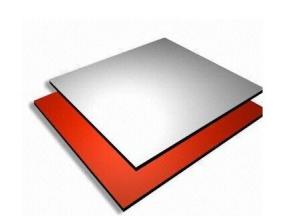

a) Front:Aluminum-alloy sheet coated with fluoro-carbon resin (PVDF) and polyester resin (PE) roasting painting;

b) Core:nontoxic polyethylene;

c) Back:Aluminum-alloy sheet coated with polyester resin painting;

d) Surface finish:Treated with PVDF and PE resin rolling roasting coating;

e) Aluminum alloy sheet thickness: 0.04~0.5mm.

Aluminum Composite Panel Characteristics

Super peeling strength;

Excellent surface flatness and smoothness;

Superior weather, corrosion and pollutant resistance;

Even coating, various colors;

Fireproof, excellent heat and sound insulation;

Superior impact resistance;

Lightweight and easy to process;

Easy to maintain.

- Q: On the national standards for aluminum - plastic plates in 2008

- Aluminum plate national standard aluminum-plastic plate national standard aluminum-plastic plate national standard aluminum-plastic plate national standard aluminum-plastic plate national standard aluminum-plastic plate national standards

- Q: China, how can sell aluminum plastic plate, it is best to have a number of stores can be compared, the thickness is about 2-3MM, the price in general how much? Advertising light box

- China in the original building materials market inside a lot, at least six or more. Do not know now is not there? I heard that the demolition of the.

- Q: OKorder Jixiang Technology Group production and sales of aluminum-plastic panels and aluminum veneer, but also what products?

- Aluminum honeycomb composite panels, titanium zinc composite panels, stainless steel aluminum composite panels, aluminum magnesium and manganese roof panels.

- Q: Aluminum-plastic curtain wall construction in winter, with the real paste can you?

- Curtain wall, there is no wet paste. The The Wet paste is the practice of decoration, used in outdoor, because the outdoor weather conditions are relatively poor, generally about two years will lead to hollowing, off the board and other serious problems! Do not talk about winter or summer construction.

- Q: Aluminum veneer, aluminum-plastic plate and aluminum honeycomb curtain wall material is different

- Aluminum veneer is a layer of pure aluminum, aluminum-plastic plate is two layers of pure aluminum plate with pvc, honeycomb aluminum plate is between the two layers of aluminum plate with honeycomb, which is the most expensive honeycomb board, followed by Aluminum veneer, and finally aluminum-plastic panels, but the need for their own processing of aluminum-plastic panels, waste, short life, according to different processing, the price will be high. Effect and quality of the best is the honeycomb board (surface smooth, strong wind pressure), very on the grade, the use of the world less, the reason is the price is too high. Life and aluminum veneer is basically the same,

- Q: Chengdu sales of aluminum-plastic plate, aluminum veneer, aluminum dealers

- Chengdu Xing Jimei curtain wall materials Co., Ltd. mainly sell aluminum, aluminum-plastic plate, aluminum veneer (the company has a number of agents such as Guangzhou Gold and well-known brands)

- Q: Home decoration, aluminum-plastic board in general how thick ah?

- Size is generally 1220 * 2440

- Q: Dear brothers and sisters please tell the little sister What are the manufacturers of aluminum-plastic factory in Guangzhou I need the name of the factory hurry!

- Guangzhou City Star and Aluminum Products Co., Ltd.

- Q: Aluminum-plastic composite plate should be set where the edge of ribs

- Side ribs are close to the position of the four folding side, ribs of the material is usually aluminum or zinc square tube,

- Q: The status of aluminum - plastic plate products

- Will be easy to process performance into shoddy

Send your message to us

PE PVDF aluminium composite panel exterior cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords