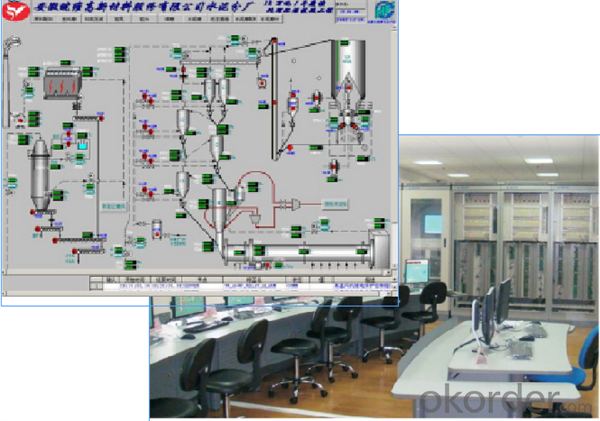

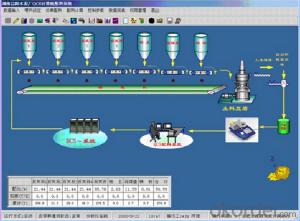

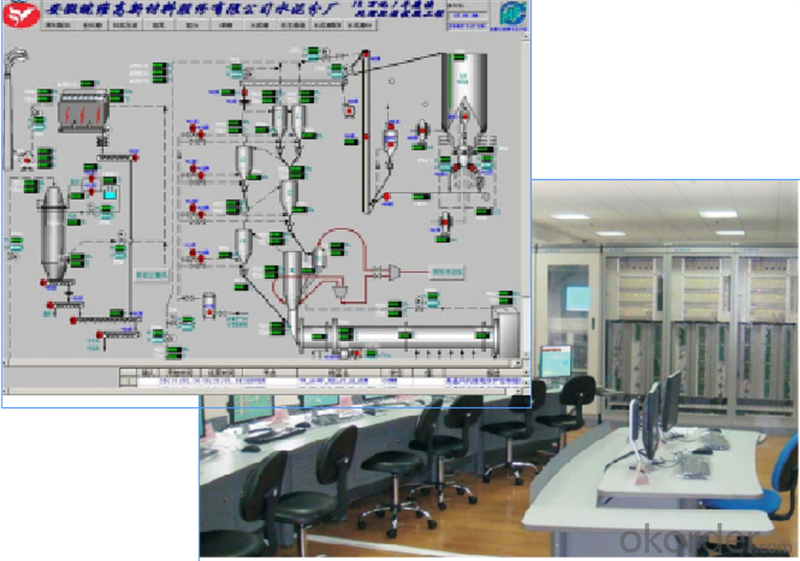

PCS Series Distributed Process Control System from China

- Supplier:

Hefei GoodTimes Automation Co.,Ltd.

Hefei GoodTimes Automation Co.,Ltd.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

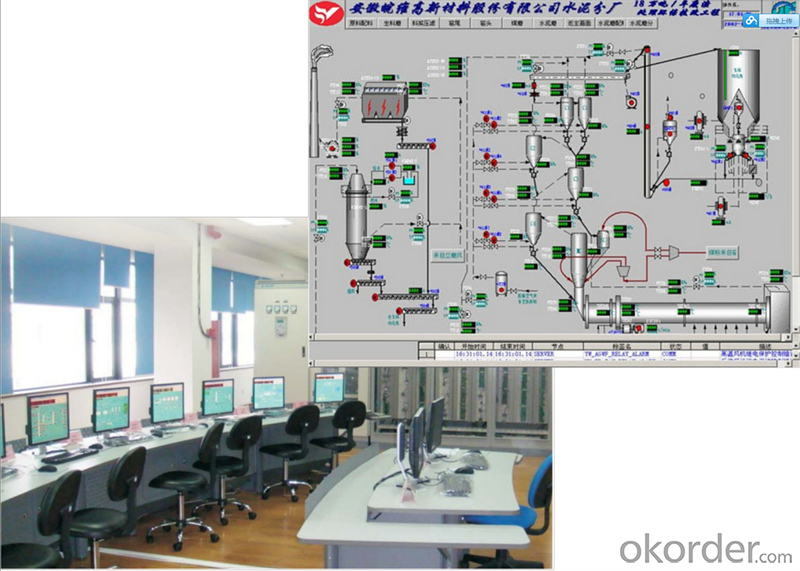

PCS Series Distributed Process Control System, applicable to different capacities and processes, is developed by our company in combination with international latest control technology and products, and control technology experience accumulation for many years in the cement industry, with aims of high reliability, low input and high performance optimized control.

Company Introduction

Hefei GoodTimes Automation Co., Ltd. is a technique oriented state-level high-tech enterprise, transformed from Hefei Jinshan Science and Technology Industrial Company organized on the basis of automation institute of Hefei Cement Research & Design Institute Corporation Ltd. under of CNBM.It was awarded the Anhui Industrial Design Center, Hefei Enterprise Technology Center, Hefei Brand demonstration Enterprise, Hefei Engineering Technology Research Center. The core team is composed of the automation laboratory of construction institute. It is a scientifific and technological enterprise with a long history and strong technical strength, which integrates scientifific research and development, equipment manufacturing, engineering settings, and technical service.The company has established a perfect quality assurance system, which has passed the authentication of ISO9001 quality management system certifification,ISO14001environment management system certifification,OHSAS18001 occupational health & safety management system certifification, level 3 work safety standardization and Certifificate for China Compulsory product certifification.It is engaged and specialized in the development of the whole series of material measurement, process control, factory power distribution and electric control, monitoring and control devices for cement production as well as their manufacturing and services. The company has inherited innovative development experience from the core team for more than 60 years. It is staffed with a professional team with fifirm grasp of the latest technology and rich practical experience. In product development, production and services, it adheres to the business concept of “Customer-centered, innovation-driven, aiming at the win-win”. The company will continue to make customers feel “carefree, assured and content"

- Q: Where is the linear guide?

- Linear guides are generally used in machine tools and precision equipment, as well as in everyday life devices such as wheelchairs, as well as in apple IPHONE.

- Q: What does the letter in the front of the THK linear guide mean, such as the HRS15A guide rail, what does HSR mean? Who has the information about this?

- THK stands for "Toughness", "High Quality (high quality)" and "Know-how" (know-how)This is found in the introduction of his company!HSR is the model, it doesn't make much sense! Just like some cell phone models!

- Q: Who knows what kind of grease the elevator guide uses?

- If the lubrication effect is good, of course, the guide rail for lubricating oil. And from an economic point of view, of course, regular oil is cheaper.The main function of the slideway lubricant is to ensure that the guide rail is not rusty and the wear of the guide shoe is reduced. The common oil can also play such a role. In order to ensure the oil absorbing cotton wick can absorb oil normally, usually add 10% of the diesel oil in the ordinary oil, and the effect is equivalent to the special lubricating oil for the slideway.

- Q: I would like to ask you, elevator maintenance instructions on the use of rail lubricants N46 oil, we can not buy here, I would like to ask what type of replacement instead of more appropriate? Thank you

- Can use 46 hydraulic oil instead of the market, in fact, many brands have no. 46 rail oil, you ask some oil distributors must sell, like Shell, Mobil, the Great Wall.

- Q: Did the Japanese THK come to China or Taiwan? ABBA, silver, CPC, stainless steel? What I want is real stainless steel, not stainless iron,

- Yes, we have。The micro guide rail of SBC is made of stainless steel.Stainless steel (Stainless Steel) is referred to as the stainless steel, the resistance of air, steam, water and other weak corrosive medium or with stainless steel known as stainless steel; the corrosion (acid, alkali, salt and other chemical etching) steel called acid resistant steel. Because of the difference in the chemical composition of the two, and make their corrosion resistance is different, ordinary stainless steel is generally not resistant to chemical medium corrosion, and acid resistant steel are generally stainless steel.

- Q: Optima cabinet drawer guide rail is used, which brand?

- Optima Exhibition cabinets are generally used in Austria Blum Blum rail. Used in the customer's home is generally pure Chinese imports of hardware, such as the German YSWJ produced in Guangdong, and even the instructions are in German, very cattle bar.The man who is anonymous must be the shooter. Everything is german.

- Q: How can the dovetail guide be fixed on the case?

- Screw. The box wall is made of wire holes, and the guide rail is provided with a waist shaped countersunk head hole.

- Q: The mechanical guideway acts as a guide Then why are they called rail pairs? What does "deputy" mean?

- 1 is for guiding and positioning2 rail pair refers to the movement of the two componentsThere must be a relative movement between the components to determine the 2 mechanism therefore, member connections should make the two member direct contact, and can have certain relative motion, the direct contact of active connections called motion. My understanding is that the two pairs of relative motion construct relationships, such as revolute pairs, as well as high pairs, low pairs, you see, mechanical principles, which are relatively simple to explain

- Q: Can I use oil for the guide rail of the machining center?

- A machining center, rail oil should be selected with low friction, 1 excellent, can reduce the plastic plating rail caused by the vibration and crawling; 2 high oxidation stability, can be used under high temperature, prolonging the service life of the oil; 3, high viscosity index, the machine starts low viscosity, high temperature can still maintain the proper viscosity, reduce oil leakage; 4, and cutting fluid such as the separation performance of the emulsion has been strengthened, prevent the emulsion away; 5, to prevent the workpiece turns; wear 6, excellent performance.Two, car oil can replace rail oil, but not when the car rail oil oil, automobile oil has several important lubricating oil additive is not common, heat, oxidation, cleaning, dispersion, mobility, and motor oil is a multi-level, such as 10W-40, can be ensured to provide lubrication performance at 25 degrees below zero. The machine tool lubricating oil is usually single stage, such as No. 40, No. 68, if added to the ordinary oil vehicle, tens of kilometers will let the engine scrap.Three, lubricating oil is actually a highly targeted service industry, for different equipment in different environments corresponding to different oil lubrication to guide oil, hot days of the south in general not the same as their high molecular viscosity.Four, recommended: special guide 68# oil processing center, North general 32# or 46# please refer to the specific machine instructions, but absolutely can not use the hydraulic oil, do not lose the greater.

- Q: The rack is fixed on the guide rail, the slider is connected to the motor, the motor is connected with the gear, can you do that?

- Yes, the design is very simple, but the accuracy is not very high

Send your message to us

PCS Series Distributed Process Control System from China

- Supplier:

Hefei GoodTimes Automation Co.,Ltd.

Hefei GoodTimes Automation Co.,Ltd.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches