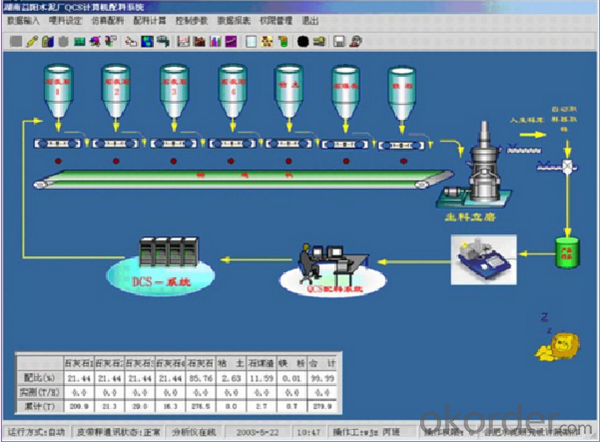

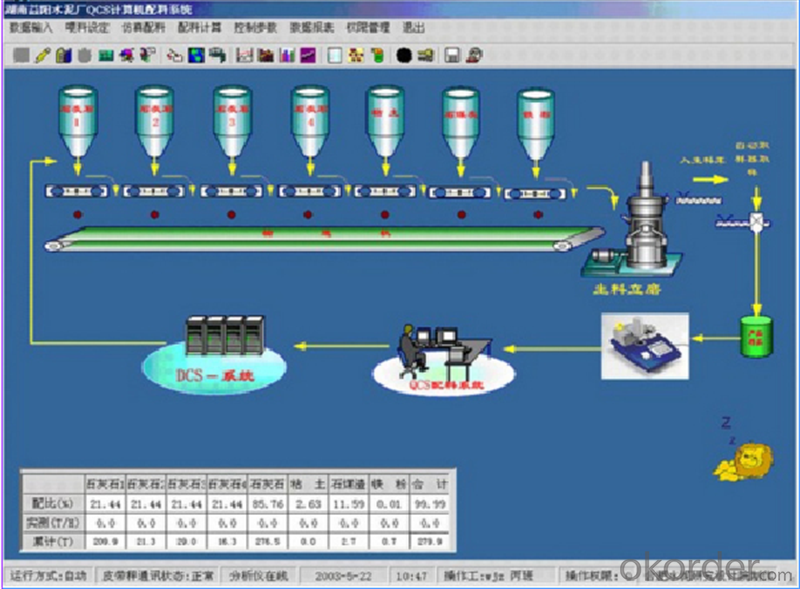

QCS Proportioning Control System with Advanced Ingredient Test

- Supplier:

Hefei GoodTimes Automation Co.,Ltd.

Hefei GoodTimes Automation Co.,Ltd.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

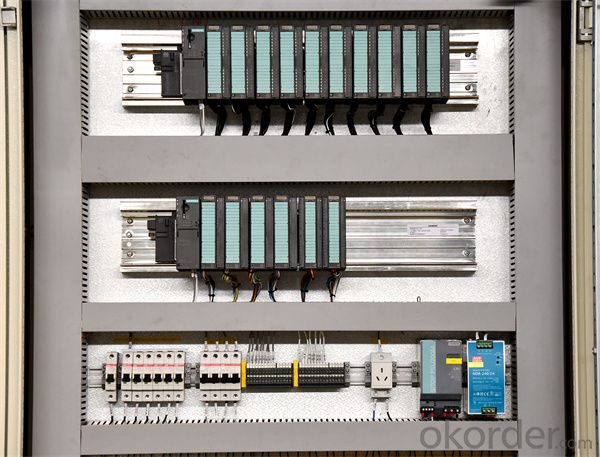

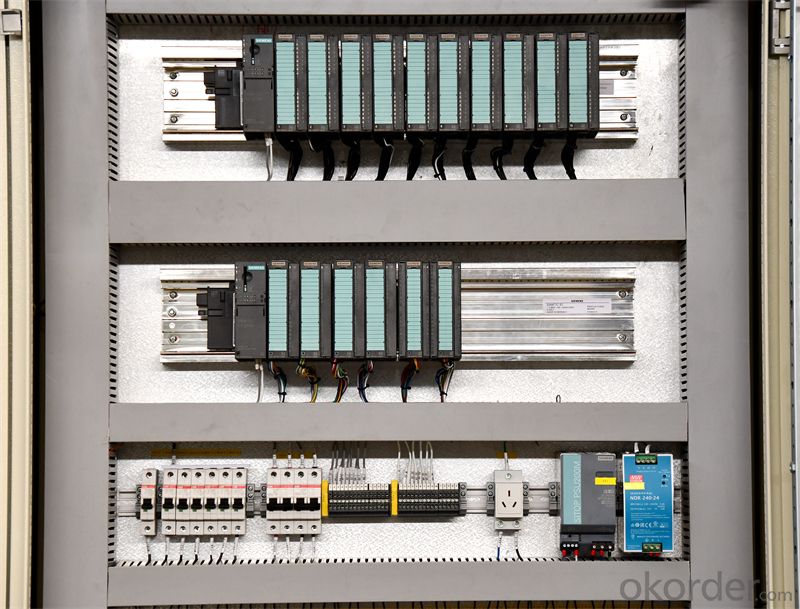

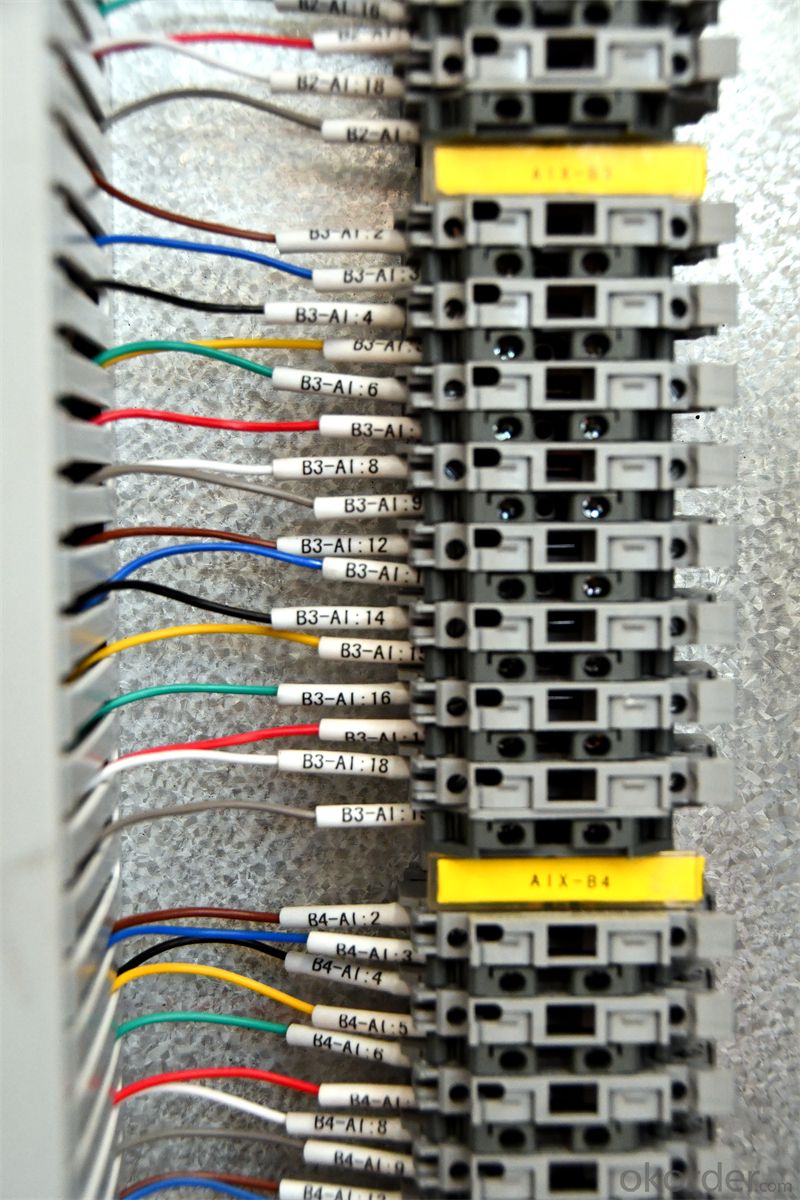

QCS Proportioning Control System has an application history of more than 30 years, with advanced ingredient test, strong software function and rich communication interfaces. The system successfully applies to 2000~ 5000t/d large and medium cement production lines, obviously stabilizing clinkering system thermal regulation and improving clinker output and quality. In particular, it has great significance for executing new standard of cement quality.

Company Introduction

Hefei GoodTimes Automation Co., Ltd. is a technique oriented state-level high-tech enterprise, transformed from Hefei Jinshan Science and Technology Industrial Company organized on the basis of automation institute of Hefei Cement Research & Design Institute Corporation Ltd. under of CNBM.It was awarded the Anhui Industrial Design Center, Hefei Enterprise Technology Center, Hefei Brand demonstration Enterprise, Hefei Engineering Technology Research Center. The core team is composed of the automation laboratory of construction institute. It is a scientifific and technological enterprise with a long history and strong technical strength, which integrates scientifific research and development, equipment manufacturing, engineering settings, and technical service.The company has established a perfect quality assurance system, which has passed the authentication of ISO9001 quality management system certifification,ISO14001environment management system certifification,OHSAS18001 occupational health & safety management system certifification, level 3 work safety standardization and Certifificate for China Compulsory product certifification.It is engaged and specialized in the development of the whole series of material measurement, process control, factory power distribution and electric control, monitoring and control devices for cement production as well as their manufacturing and services. The company has inherited innovative development experience from the core team for more than 60 years. It is staffed with a professional team with fifirm grasp of the latest technology and rich practical experience. In product development, production and services, it adheres to the business concept of “Customer-centered, innovation-driven, aiming at the win-win”. The company will continue to make customers feel “carefree, assured and content"

- Q: Which kind of slideway is good for engraving machine?

- The engraving machine track can be divided into two categories, circular rail and side rails, the precision and service life, the side rail is the best, but the price is relatively high, circular orbit selection of domestic brands can, the price of 100 yuan / square meters, rail brand more, imported from Taiwan. HIWIN TBI ABBA SBC, there are a lot of intime brand price difference, the quality of silver is better, but fakes on the market more, note the time of purchase.

- Q: The boss asked me to write an article on a double axle linear guide, but what is a two center linear guide rail? Who can tell me?

- 1 axle guide rail is a kind of light load high-speed guide rail. The matching of the slide block and the roller is formed in one body. It falls into two categories. Were built in two axis linear guide, also called the inner slide series, slider rail, ISG series of double axis guide rail; external dual axis linear guide, also called the outer sliding rail, slide rail outside, OSG series of double axis guide rail. Built in double axle linear guide rail means that the two axle rail is installed inside the guide rail, and the slide block is basically the same as the rail width. The external double axle linear guide rail means that the double axle rail is installed outside the guide rail, and the slider is wider than the guide rail.2, Nkole, double axis guide rail (daogui), guide, rail:, metal or other materials. A device that holds, holds, guides, or reduces friction of a moving device or device. A longitudinal groove or ridge on the surface of a guide, used for guiding and fixing machine parts, special equipment, instruments, etc.. The guide rail, also known as linear guide, linear slide rail, for linear reciprocating movement, linear bearings have higher than the rated load, and can bear a certain torque, can achieve high precision linear motion under high load

- Q: Excuse me, teachers""The straightness of the guide rail is in the vertical and horizontal planesHow do you understand the vertical and horizontal surfaces?Thank you, studentThe following question can not be continued (last question)A private | fake public six grade teacher!!!Thank you, teacher.Straightness tolerances such as rails, see some drawings required 0.01, some are 0.0018, and so onWould you please tell me the principle or method of determining this tolerance?

- There are two rails in a car! The right and left move is called the Z axis, which controls the length of the male part! The front and rear movement is called the X axis, controls the workpiece diameter size! All lathes have only two axes, the X and Z axes! It's easier to learn the car before you learn to count the cars!

- Q: Can the linear guide bend?

- We have a Italy guide rail that can be of any radius or curve. I wonder if I can meet your application. Can be specific understanding

- Q: EPSON stylus printer LQ-630K how to put the ribbon rail into the print head?

- It's not easy to imagine and understandYou put the box in the core with lewd printer driver frame the ribbon guide and ribbon set well is to slant along the print head on both sides of the groove insert more attention to it bulldozed to note that there is a middle small diamond plastic hook in the print ribbon guide frame that it can be installed guide to attention when the ribbon is not squeeze or print out is not blank word installed after the test print before you boot you try a little mobile print head see ribbon on the gear knob is rotated it

- Q: Is there a national standard for rail lift? Or approximate? Which kind of elevator belongs to the special equipment?

- Technical code for safety of installation, use and disassembly of JGJ 215-2010 construction liftsGBT 10054-2005 construction hoistGB 7920.3-1987 lift terminologySafety regulations for GB 28755-2012 simple lifts

- Q: Optima cabinet drawer guide rail is used, which brand?

- Optima Exhibition cabinets are generally used in Austria Blum Blum rail. Used in the customer's home is generally pure Chinese imports of hardware, such as the German YSWJ produced in Guangdong, and even the instructions are in German, very cattle bar.The man who is anonymous must be the shooter. Everything is german.

- Q: What kinds of guideways are there in NC machine tools?

- Frequently encountered rail has 2Hard rail gauge, and.The line rail is a linear guideway consisting of a guide element and a moving element. The fixed element is mounted on the machine tool and the moving element is mounted on the table or other moving parts. Wire and rail are usually used in mechanical structures with higher requirements, such as straightness, parallelism, etc.. THK, Tianjin, Romania, HIWIN and other manufacturers have related products, their official website has an introduction and product samples.Hard rail is directly machined on the machine bed, column, and other fixed parts (rails and fixed components are integrated), through the sliding seat and work table or other moving parts. In order to ensure accuracy, but also in the rail scraping research.Features: to gauge rolling friction speed, high positioning accuracy. The carrying capacity is approximately insufficient (hence, a ball guide and roller guide are derived)Hard rail belongs to sliding friction, but its bearing capacity is large, but its moving speed is slow

- Q: Can the elevator guide stand be fixed on ordinary red bricks?

- Then you need wall bolts. You can't simply use expansion wires

- Q: What safety matters should be paid attention to when installing the guide rail of elevator?

- 7588 - 4.2.1, each rail should have at least 2 guide brackets, and its spacing is not greater than 2.5m.7588 - 4.2.1 with the weld welding support should be continuous, and should be double welded.The 10060 - 4.2.7 car rail and the counterweight rail with the safety clamp shall be supported on the solid rail seat at the lower end of the road.The distance between the top of the car guide rail deviation is 0 ~ +2mm.The distance between the top of the heavy rail deviation is 0 ~ +3mm.10060 - 4.2.3 each rail working face (including side and top surface), the deviation of each datum line of the installation datum line shall be no more than the following value: the car rail and the counterweight rail with the safety tongs are 0.6mm, 5m.10060 - 4.2.3 without safety tongs, T type counterweight rail is 1.0mm.10060 - 4.2.3 piecewise continuous test on each 5m plumb line (at least 3 times), 2 times of the maximum relative deviation of measurement value should be less than the prescribed value.10060 - 4.2.3 piecewise continuous test on each 5m plumb line (at least 3 times), 2 times of the maximum relative deviation of measurement value should be less than the prescribed value.10060 - 4.2.4 car rails and counterweight rails face joint is provided with a safety gear should be continuous at the gap, and the local gap is less than 0.5mm, no safety gear of heavy rail joint gap should not be greater than 1mm.10060 - 4.2.4 rail joints, the steps should be no more than 0.05mm, without the security clamp on the heavy rail, the joint shall be no more than 0.15mm.10060 - 4.2.4 light length is more than 150mm.

Send your message to us

QCS Proportioning Control System with Advanced Ingredient Test

- Supplier:

Hefei GoodTimes Automation Co.,Ltd.

Hefei GoodTimes Automation Co.,Ltd.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches