Painted Metal Steel Scaffolding for Sale(QS)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Model Number: | |||||

| Scaffolding Type: | Usage: | Color: | |||

| Surface Treatment: | Technique: | Material: | |||

| Life Span: | Main Tube Diameter: | Tube thikness: |

Packaging & Delivery

| Packaging Detail: | Steel Scaffolding for Sale: Barely packed in the container or as you required. 23 tons per 20GP container. |

| Delivery Detail: | 20 work days after deposit |

Specifications

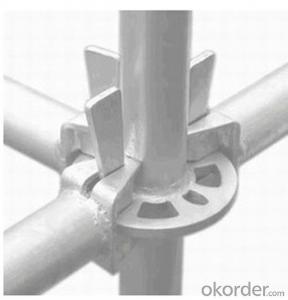

Scaffolding for Sale

1.Painted surface, rust-proof

2.Easy assembly and disassembly, time saving

3.SGS certified

Specifications of Steel Scaffolding for Sale

| Main parts | Mode No. | Quantity | Height/Length |

| Standard | QL001 | 4 | 700/1000/1300/1900/2500mm |

| Ledger | QL001 | 8 | 600/900/1200/1800mm |

| Plate | JP 001 | 8/16 | |

| Blade | LP 001 | 16 |

1. We are manufacturer with more than 14 years experience.

2. We are certified by SGS,BV

3. We have a factory which covers an area of 8000sqm and its daily output is more than 50 tons, so we can assure you the punctual delivery.

- Q: Are there any alternatives to steel props?

- Yes, there are several alternatives to steel props in construction and temporary support systems. Some common alternatives include aluminum props, timber props, and composite props. These alternatives are chosen based on factors such as load capacity, cost, ease of installation, and specific project requirements.

- Q: Can steel props be used in shopping mall construction?

- Indeed, shopping mall construction can make use of steel props. These props, also referred to as adjustable steel props or steel shoring props, find frequent application within the construction sector for their ability to provide temporary support to structures. Their usage is particularly prevalent in the construction of multi-story buildings, such as shopping malls, where added reinforcement is necessary to bear heavy loads and cater to the varying stages of construction. The versatility of steel props lies in their adjustable height, rendering them suitable for a range of construction requirements. By design, these props ensure stability and safety to the structure, while their installation, maintenance, and removal are easily accomplished as per need. All in all, steel props stand as a dependable and frequently employed solution within the realm of shopping mall construction.

- Q: Are there any regulations or guidelines for using steel props in construction?

- Indeed, regulations and guidelines exist for the utilization of steel props in construction. Steel props, also referred to as adjustable steel props or acrow props, serve as temporary support structures utilized for vertical support during construction or renovation endeavors. These props are commonly employed to provide support for walls, floors, ceilings, and other structures. Various countries enforce regulations concerning the use of steel props in construction, which are established by local building codes and standards. These regulations guarantee the safety and stability of structures while safeguarding workers and occupants of the building. The specific regulations may differ depending on the jurisdiction, encompassing aspects such as design, installation, maintenance, and load-bearing capabilities. One well-regarded guideline for employing steel props is the European Standard EN 1065, which outlines specifications for adjustable steel props used in temporary structures. This standard defines several technical parameters, including the maximum load capacity, permissible deflection, and adjustment range for different sizes of props. Adhering to this standard ensures the safe and effective utilization of steel props. Moreover, construction companies and contractors frequently adhere to industry best practices and guidelines furnished by professional organizations or trade associations. These guidelines may offer recommendations on the proper usage, installation, inspection, and maintenance of steel props. It is pivotal to adhere to these guidelines to ensure the correct utilization of props and minimize potential risks or hazards. To summarize, the utilization of steel props in construction is subject to regulations and guidelines that strive to ensure their safe and effective usage. Compliance with local building codes, standards like EN 1065, and industry best practices is imperative for upholding the structural integrity and safety of construction projects. Construction professionals must stay abreast of the latest regulations and guidelines to ensure compliance and promote safe construction practices.

- Q: Are steel props adjustable during construction?

- Yes, steel props are adjustable during construction. They are designed with adjustable components such as pins or screws that allow for height adjustment to support different load requirements and accommodate varying construction needs.

- Q: How do you ensure proper load distribution when using multiple steel props?

- When using multiple steel props, there are several steps that can be taken to ensure proper load distribution: 1. Determine the load requirements: Before using steel props, it is important to accurately determine the load requirements for the structure or object being supported. This involves calculating the total weight or force that needs to be distributed among the props. 2. Use an appropriate number of props: The number of steel props required will depend on the load requirements. It is crucial to use an adequate number of props to evenly distribute the load. Using too few props can result in an uneven distribution, leading to stress concentration and potential failure. 3. Position the props correctly: The placement of the steel props plays a critical role in load distribution. They should be positioned at regular intervals along the load-bearing structure to evenly distribute the load. The distance between the props should be determined based on the load requirements and the strength of the props. 4. Ensure proper alignment: The steel props should be aligned properly to avoid any eccentric loading. Eccentric loading occurs when the load is not applied at the center of the prop, causing uneven distribution. It is important to ensure that the props are plumb and aligned vertically to prevent any tilting or leaning. 5. Adequate prop capacity: Each steel prop should have adequate load-bearing capacity to handle the assigned load. It is essential to check the load capacity of each prop and ensure it exceeds the calculated load requirement. Using props with insufficient capacity can lead to overloading and potential collapse. 6. Regular monitoring and adjustment: After setting up the steel props, it is important to regularly monitor the load distribution and make necessary adjustments if any imbalances or shifts occur. This can be done through visual inspections, load testing, or monitoring devices. Regular monitoring ensures that any potential issues are detected and addressed promptly. By following these steps, proper load distribution can be ensured when using multiple steel props, reducing the risk of structural failures and ensuring the safety of the supported structure or object.

- Q: Can steel props be used in supporting temporary exhibition booths?

- Temporary exhibition booths can indeed benefit from the use of steel props. These props provide a robust and dependable support system for structures of this nature. They offer the added advantage of adjustability, as their height can be modified to accommodate various locations or uneven surfaces. Moreover, steel props are highly regarded for their ability to bear heavy loads, making them an ideal choice for supporting exhibition materials, displays, and equipment. Furthermore, their durability and resistance to wear and tear ensure the stability and safety of the temporary booth throughout its usage. All in all, steel props are widely favored in the construction and support of temporary exhibition booths due to their strength, versatility, and reliability.

- Q: What are the different types of steel prop braces available?

- There are several different types of steel prop braces available, including adjustable steel props, push-pull props, tilt props, and diagonal steel braces. These braces are used in construction and formwork systems to provide support and stability to vertical structures.

- Q: Do steel props require any special permits for installation and use?

- Yes, steel props typically require special permits for their installation and use. The specific permits needed may vary depending on local building codes and regulations. It is advisable to consult with local authorities or a licensed engineer to ensure compliance with all necessary permits and regulations before installing and using steel props.

- Q: Are steel props suitable for supporting temporary exhibition or display structures?

- Yes, steel props are suitable for supporting temporary exhibition or display structures. Steel props provide strong and stable support, making them ideal for holding up structures and ensuring their stability throughout the duration of the exhibition or display.

- Q: Can steel props be used in pipeline construction?

- Yes, steel props can be used in pipeline construction. Steel is a strong and durable material that can provide the necessary support and stability required for pipeline installations.

Send your message to us

Painted Metal Steel Scaffolding for Sale(QS)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords