Painted Galvanized Corrugated Plate / Sheet -SPCC in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Prepainted Galvanized Steel:

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Prepainted Galvanized Steel qualified with excellent decorative, formability, corrosion resistance, coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material; for manufacturing board.

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

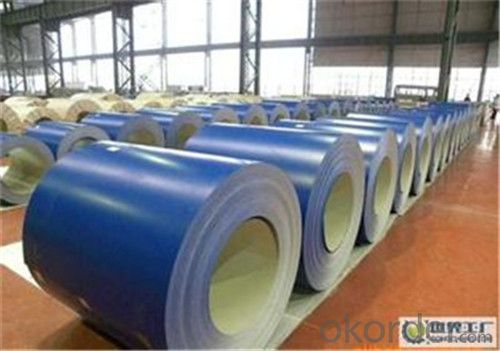

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

50MT, it is for one container.

2.Whether your company have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the

- Q: How are steel coils used in the manufacturing of automotive hoods?

- Steel coils are used in the manufacturing of automotive hoods as they are shaped and formed into the desired hood design. These coils are processed through various stages such as cutting, stamping, and welding to create the hood's structure. The strength and durability of steel make it an ideal material for automotive hoods, ensuring they can withstand impacts and provide protection to the engine compartment.

- Q: Im going to buy T-304 Stainless Steel exhaust tips for my truck. Is T-304 Stainless Steel good metal?

- Surprisingly any stainless steel is considered soft or tough metal. A hardness tester will bare this out. It resists work hardening which means you can bend it many more times than cold rolled or hot rolled steel before it will break. Your choice is a good one for your intended purpose.

- Q: help me and my twin love this cutie in our form !? how do we steel hime from bitchey rebecca!? X X X xX

- I have the same problem, but without being a twin lol. I'm just guna play it very very dirty, I'm not usually a slut, but i hate to loose, and you do have an advantage, all boys like twins. Hope this helps. xx

- Q: full discription about hydrolics used in steel melting shop with hyd valve is use in thair circit too ?

- The correct spelling is hydraulics. I haven't heard the term steel melting shop you probably means a foundry or a steel mill The most obvious example i can think of is hydraulic-operated fork lifts. Hydraulic cylinders are used to lift the forks and to tilt them upwards or downwards. The valves are coneccted to levers next to the steering wheel. Hydraulic pressure is supplied by a hydraulic pump driven by a propane or diesel engine. In some forklift designs the wheels are also not connected directly to the engine, but driven by hydraulic motors. There are also a large variety of machines used in steel mills and metalworking companies to cut and shape metal parts. for example, press brakes, plate cutting shears, stamping presses, hole punch machines, drawing presses, etc. These types all operate in much the same basic way. They use a very large cylinder or group of cylinders to apply many tons of force to different kinds of metal working tools.

- Q: Iron melts faster when there will be low carbon in Iron.During steel making the molten Iron gets purified and alloying being done through the process. How the carbon is being controlled at Iron melting stage and what it is called?

- Steel is usually made in a two-step process. As you may know, carbon, in the form of coke, is added to the iron ore during the initial smelting process. This is the first step. The conversion of iron ore into raw iron is accomplished with a blast furnace. Carbon dissolves with the iron during the smelting process. The amount of carbon in the iron is generally not controlled at this point as this would be too difficult, the excess carbon is removed in the next step. The result is pig iron which is crude iron that has a very high carbon content, and a large amount of impurities. Pig iron is almost as brittle as glass, and it is useless in this form. In most modern steelmaking operations, molten pig iron is tapped from the blast furnace three or four times per day- it is not allowed to cool. The liquid pig iron is carried in ladles directly to a Basic Oxygen Furnace which converts the pig iron into steel. The basic oxygen converter uses a stream of pure oxygen to burn off the excess carbon. Impurities are also burned off, particularly phosphorus, silicon, and sulfur (which damage the steel's properties.) These elements all have a much higher affinity for oxygen than iron does, so the iron itself remains unchanged. Once the carbon content and the impurities are reduced to the desired level. The oxygen is shut off, and the iron has now become steel. At this point other alloying elements may be added, such as chromium, manganese, or molybdenum. These elements improve the steel's properties, but also add to it's price. If necessary, more carbon can be added as well if the carbon content has accidentally dropped too low. Finally, molten steel from the basic oxygen furnace is poured off. It can be cast into ingots, billets, or thin slabs.

- Q: I have hundreds of pounds of scrap steel... who purchases this steel and what is the price per pound etc. of this? Does someone pick it up or do I bring it somewhere?

- Right now, steel is worth $150/ton. Who purchase it? Well, not every scrap yard handle steel, you have to call them up, or look at the company name that has the word steel or iron. But price can vary from each scrap yard. Try to call around. As for someone to pick it up, the scrap yard will mostly charge you a trucking fee and then the price for steel would be lower. But here is another bad thing if you have it pick up. I know some scrap yard are bad...reall bad..they will skim off some weight...a 1k lbs to 2k lbs. Wish you good luck!

- Q: What are the different surface treatments available for steel coils?

- There are several different surface treatments available for steel coils, including galvanizing, painting, and powder coating. Galvanizing involves applying a layer of zinc to the surface of the steel to provide corrosion resistance. Painting involves applying a layer of paint to the surface to enhance its appearance and protect it from rusting. Powder coating is a process where dry powder is electrostatically applied to the steel surface and then cured under heat to form a protective and decorative coating.

- Q: What are the best types of steel for swords

- steel is the best material for a real sword

- Q: How are steel coils used in the manufacturing of solar panels?

- Steel coils are used in the manufacturing of solar panels primarily for the structural support and durability they provide. These coils are often used to construct the frames and mounting systems that hold the solar panels in place. The strength of steel ensures that the panels remain stable and secure, even in harsh weather conditions. Additionally, steel coils can be shaped and formed to meet the specific design requirements of solar panel installations, making them a crucial component in the manufacturing process.

- Q: I am making a permanent magnet, just for fun. I am trying to find the best grade of steel to do so with.

- The type of steel you require is Steel ( Iron + Carbon, mainly.),{many different types of steel } with a high Cobalt and Nickel content. These alloyed together give the best Permanent Magnets, mainly due to their own individual magnetic properties / characteristics being retained in the Alloy. All 3 metals can be magnetised by there own, but Cobalt is known to cause cancer. Nickel, is poisonous and can also cause sever Dermatitis and the destruction of skin tissue.But when alloyed together with Iron they are pretty harmless. Interesting thing is, All of these metals (in this case Elements) can share the same Mass Number ( 60 ). And yet are totally different in their other properties beside Magnetism. Cobalt - Samarium - alloys, create some of the worlds most powerful permanent magnets. And were used in medicine, But are now superseded by Neodymium magnets which are employed instead. Edit; What you could try is, mild steel which is widely available and easily found. . The steels mentioned above are pretty exclusive materials and I personally would not know how to test for their contents, of which they are made from. Soft Iron is good for making electro-magnets if you fancy a go at making one. .

Send your message to us

Painted Galvanized Corrugated Plate / Sheet -SPCC in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords