Painted Galvanized Corrugated Plate / Sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Prepainted Galvanized Steel:

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Prepainted Galvanized Steel qualified with excellent decorative, formability, corrosion resistance, coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material; for manufacturing board.

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

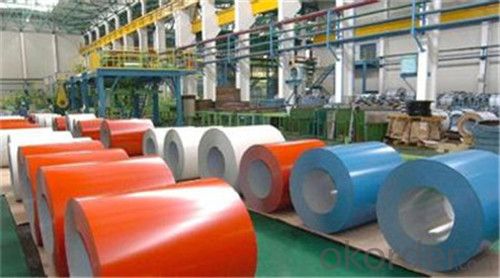

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

50MT, it is for one container.

2.Whether your company have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the

- Q: What is the diffrent Aluminized steel Type 1. stainless steel 409 430?

- Alloy steel is a stainless steel. The differences between the two are the composition of the metal. Alloy steel is steel with usually less than 5% of other elements, like molybdenum, copper, chrome while stainless steel is a steel with at least 10-11% of chromium.

- Q: I found this amazing kid on youtube - is he using nylon or steel strings?(I'm buying my first guitar! helpp)oh and is fingerstyle also possible in steel string guitar? does it hurt?(I might sound really stupid-..)thanks a lot

- Lol that's sung ha jung. You can play with both types but it is easier to start off learning in nylon.

- Q: How are steel coils heat treated?

- Annealing is the method used to heat treat steel coils, resulting in improved mechanical properties and overall performance. To achieve this, the coils are heated to a specific temperature and slowly cooled down. This process relieves internal stresses within the steel and enhances its performance. To begin the heating process, the steel coils are raised to a critical temperature, typically between 800°C and 900°C, depending on the desired outcome. They are then maintained at this temperature for a specific period of time, allowing for the transformation of the steel's microstructure. Once the desired time has passed, the heated coils are carefully cooled down in a controlled manner. This gradual cooling process is crucial as it allows for a uniform and refined microstructure. It also helps prevent the formation of internal stresses that could weaken the steel. The annealing process can be conducted in various atmospheres, such as air, nitrogen, or hydrogen. The choice of atmosphere depends on the specific requirements and properties desired for the steel coils. For example, annealing in a protective atmosphere like nitrogen or hydrogen can prevent oxidation or decarburization of the steel surface. In conclusion, annealing is a crucial step in heat treating steel coils, resulting in improved mechanical properties, enhanced formability, and the desired characteristics for industrial applications.

- Q: How are steel coils used in the production of oil and gas pipelines?

- Steel coils are used in the production of oil and gas pipelines as they serve as the primary material for constructing the pipes. These coils are formed into tubes and welded together to create a continuous pipeline that can transport oil and gas over long distances. The steel coils provide strength, durability, and corrosion resistance to withstand the harsh conditions of oil and gas transportation, ensuring the safe and efficient delivery of these resources.

- Q: What are the dimensions of steel coils used in the industrial machinery industry?

- In the industrial machinery industry, the dimensions of steel coils can vary depending on the specific application and requirements. However, it is generally observed that steel coils used in this industry typically have a width ranging from 600 to 2,000 millimeters (24 to 79 inches) and a weight ranging from 2 to 25 metric tons (4,400 to 55,100 pounds). The core, or inner diameter, of the coil can range from 508 to 762 millimeters (20 to 30 inches). Furthermore, the thickness of the steel coil can range from 0.4 to 25 millimeters (0.016 to 0.98 inches). These dimensions may experience variations according to the specific needs and specifications of the machinery being manufactured or used in the industrial machinery industry.

- Q: what is the chemical process that makes steel harder when it is heated and cooled rapidly?what does the heating of it do to the atoms?what does the cooling of it do to the atoms?what makes tempered steel so strong compared to untempered steel?

- You can't temper all steels. Generally the material must be a high-carbon or tool steel. Different alloys temper differently, and tempering is usually done to get a specific set of characteristics, so you must know what you are working with and use the right methods and temperature. If you do it wrong, the material may be hard but too brittle for the purpose or have other issues. It can be simple, such as heating to a dull red, carbonizing the surface (use an acetylene rich flame until it blackens the surface) and oil quenching. Do that to a piece of tool steel (like a screwdriver) and it will case (surface) harden it to the point you can't scratch it with a file. Tempering changes the way the molecular structure in the metal is linked and oriented.

- Q: Can steel coils be perforated?

- Yes, steel coils can be perforated. Perforation involves creating a series of holes or small openings in the surface of the steel coil, which can be done for various reasons such as improving ventilation, reducing weight, enhancing aesthetics, or facilitating specific applications.

- Q: How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being processed and formed into various components such as shelves, brackets, and support beams. These coils are typically cut, bent, and welded to create the necessary shapes and sizes required for the shelving unit. The steel material provides strength and durability to the shelves, ensuring they can hold heavy items and withstand the weight placed on them.

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with a zinc-nickel alloy. Zinc-nickel alloy coating provides excellent corrosion resistance and is commonly used in various industries including automotive, construction, and manufacturing.

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- *Carbon steel, also called plain carbon steel or Mild Steel, is steel where the main alloying constituent is carbon. The AISI defines carbon steel as: Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60. If it crosses limit as said, it will come under alloy steel. ASTM A 106 gr B is a carbon steel pipe and seamless Pipe for High Temperature Service. So, it will be a mild steel comes under carbon steel category.

Send your message to us

Painted Galvanized Corrugated Plate / Sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords