Painted Aluminum Sheets Price for Color Coated Aluminium Coils for Window Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

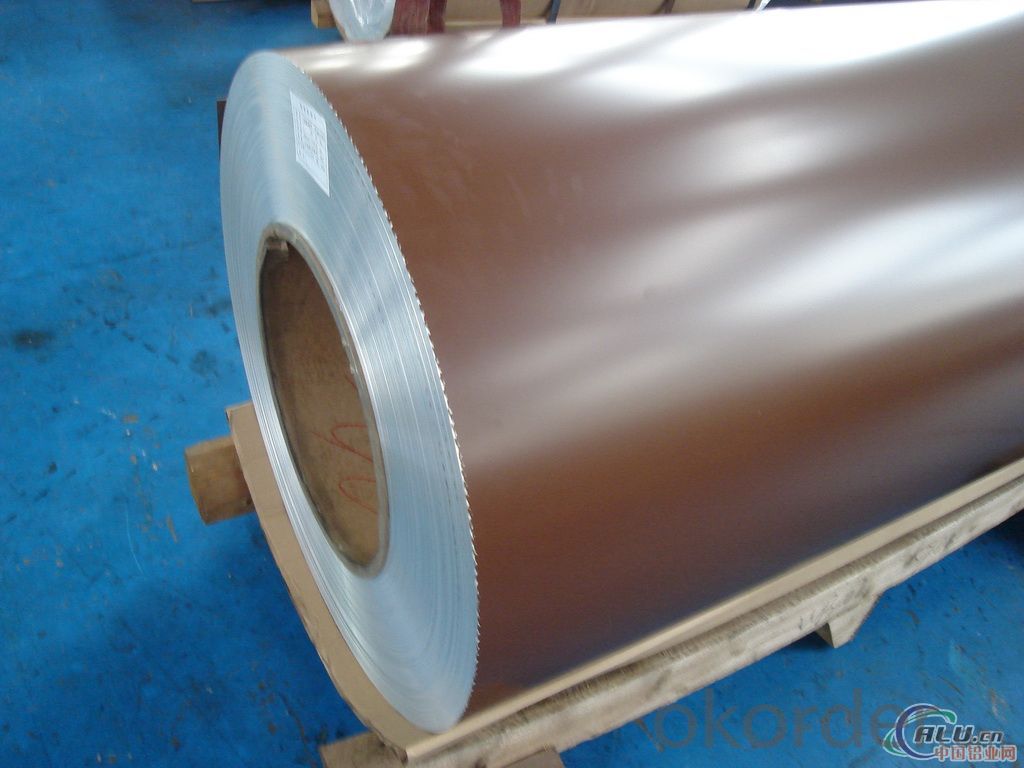

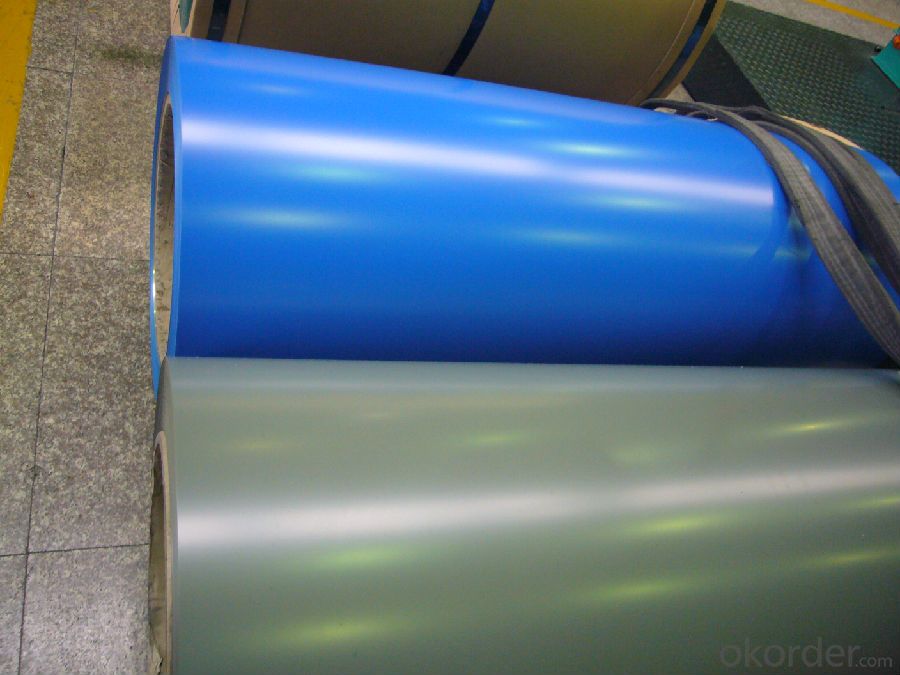

1.Structure of Color Coated Aluminium Coils for Window Decoration

Color Coated Aluminium Coils for Window Decoration is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Coated Aluminium Coils for Window Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Color Coated Aluminium Coils for Window Decoration

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the rules or laws concerning the application of flame-retardant coatings on aluminum sheets?

- <p>Yes, there are regulations regarding the use of flame-retardant coatings on aluminum sheets. These regulations vary by country and application, but they generally aim to ensure safety and compliance with fire safety standards. In the United States, for example, the National Fire Protection Association (NFPA) provides guidelines, and building codes like the International Building Code (IBC) may specify requirements for flame retardancy. The European Union has its own set of standards, such as EN 13501, which classifies the reaction to fire performance of construction products. Compliance with these regulations is crucial to ensure that the aluminum sheets and their coatings meet the necessary safety standards and to avoid legal penalties.</p>

- Q: How does the surface treatment of aluminum sheet affect its appearance?

- The surface treatment of aluminum sheet greatly affects its appearance. Aluminum, in its natural state, has a shiny and reflective surface that can be enhanced or altered through various surface treatments. One common surface treatment for aluminum sheet is anodizing. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. This treatment can produce a wide range of colors and finishes, from vibrant and opaque to translucent and metallic. Anodized aluminum sheets can have a sleek, modern appearance and are commonly used in architectural and decorative applications. Another surface treatment option is painting or powder coating. These processes involve applying a layer of paint or powder to the aluminum sheet's surface. This treatment allows for customization in terms of color, texture, and finish. Painted or powder-coated aluminum sheets can have a smooth, glossy appearance or a textured, matte finish depending on the desired outcome. This treatment is commonly used in industries such as automotive, aerospace, and construction where aesthetics and durability are important. Further, aluminum sheets can undergo mechanical surface treatments such as brushing or polishing. Brushing involves creating parallel lines on the surface of the sheet using abrasive pads, resulting in a brushed or satin finish. This treatment can give aluminum sheets a contemporary, industrial look. Polishing, on the other hand, involves buffing the surface to a high gloss, mirror-like finish. This treatment is often used for decorative purposes, such as in the production of jewelry or household items. Overall, the surface treatment of aluminum sheet plays a crucial role in determining its appearance. Whether it is anodizing, painting, powder coating, brushing, or polishing, each treatment offers a unique visual effect that can enhance the aesthetic appeal of the aluminum sheet for specific applications and industries.

- Q: Can the aluminum sheets be used for manufacturing electrical connectors?

- Indeed, electrical connectors can be manufactured using aluminum sheets. The lightweight and exceptional conductivity of aluminum render it ideal for the efficient transmission of electricity. Its outstanding conductivity and ability to resist corrosion make it a frequently employed material in diverse electrical applications, particularly connectors. Furthermore, the malleability and ease with which aluminum can be molded into diverse connector designs make it an adaptable material for the production of electrical connectors.

- Q: Can aluminum sheets be used as a substitute for steel in certain applications?

- Yes, aluminum sheets can be used as a substitute for steel in certain applications. Aluminum is a lightweight and versatile material that offers several advantages over steel. It has a high strength-to-weight ratio, meaning it can provide the same strength as steel while being significantly lighter. This makes aluminum sheets an excellent choice for applications where weight reduction is critical, such as in aerospace, automotive, and transportation industries. Additionally, aluminum is highly resistant to corrosion, which eliminates the need for additional protective coatings or treatments. This property makes aluminum sheets suitable for applications in marine environments or other corrosive conditions. Aluminum sheets also exhibit excellent thermal conductivity, making them ideal for applications that require heat dissipation, such as heat exchangers or radiators. Furthermore, aluminum is more malleable than steel, allowing for easier shaping and forming. This characteristic makes aluminum sheets suitable for applications that require complex or intricate designs. However, it is important to note that aluminum has a lower tensile strength compared to steel. Therefore, in applications that require high load-bearing capacities or structural integrity, steel may still be the preferred choice. In such cases, a careful evaluation of the specific requirements and trade-offs between weight, strength, and cost should be considered before deciding on using aluminum sheets as a substitute for steel.

- Q: I'm was thinking of buying an aluminium bike but I saw some good bikes with hi-ten.

- John and WLE, I hate to disagree... When it comes to bikes in the quality that is presented, the high tensile steel model will be the better one. On lower priced bikes, aluminum frames tend to be heavier than steel due to the low-zoot material. It is a fact that aluminum AS A MATERIAL is half the weight of steel. It is also a fact that it is 1/3 the strength. To make a low end aluminum frame as strong as a steel one, more material has to be added and will be heavier than the steel one. There is a reason that you see more aluminum bikes than steel at places like Walmart. They are cheaper to make. Unless you plan to spend HALF AGAIN what you are looking at for an aluminum bike over a steel model, don't bother... just stay with the steel one.

- Q: could magnet attract iron with the seperation of rubber and aluminum sheets?

- it does within the range of magnetic force.

- Q: Can aluminum sheets be anodized without affecting their dimensions?

- Yes, aluminum sheets can be anodized without significantly affecting their dimensions. Anodizing is a surface treatment process that forms a protective layer on the aluminum, and it does not significantly alter the overall dimensions or shape of the sheet.

- Q: What are the different methods of surface cleaning for aluminum sheet?

- There are several methods for cleaning aluminum sheets, each with its own advantages and suitability for different situations. Some of the common methods include: 1. Mechanical Cleaning: This method involves using abrasive materials, such as sandpaper or wire brushes, to physically scrub away dirt, oxidation, or other contaminants from the surface of the aluminum sheet. Mechanical cleaning is effective for removing heavy stains or corrosion, but it may leave scratches on the surface. 2. Chemical Cleaning: Chemical cleaning involves using various cleaning agents or solvents to dissolve and remove dirt, grease, or oxidation from the aluminum sheet. These cleaning agents can be acidic, alkaline, or neutral, depending on the specific requirements. Chemical cleaning is often used for removing light stains or surface oxidation, and it is suitable for large-scale cleaning operations. 3. Electrolytic Cleaning: This method uses an electric current to remove contaminants from the surface of the aluminum sheet. The sheet is immersed in an electrolyte solution, and the application of a direct current causes the contaminants to dissolve and separate from the surface. Electrolytic cleaning is effective for removing heavy oxidation, corrosion, or stubborn stains. 4. Ultrasonic Cleaning: Ultrasonic cleaning involves placing the aluminum sheet in a tank filled with a cleaning solution and subjecting it to high-frequency sound waves. These sound waves create tiny bubbles in the cleaning solution, which collapse upon contact with the surface of the sheet, dislodging dirt particles. Ultrasonic cleaning is suitable for removing fine particles, oils, or grease from the surface of the aluminum sheet. 5. Steam Cleaning: Steam cleaning utilizes high-pressure steam to remove dirt, grime, or contaminants from the surface of the aluminum sheet. The high temperature and pressure of the steam break down the dirt particles and sanitize the surface. Steam cleaning is effective for removing oils, greases, or organic residues from the sheet. When selecting a cleaning method for aluminum sheets, it is essential to consider the nature and severity of the contamination, the desired level of cleanliness, and the specific requirements of the application. It is also important to follow safety guidelines and use appropriate protective equipment when handling cleaning agents or working with electrical equipment.

- Q: Can aluminum sheets be etched or engraved?

- Indeed, it is possible to etch or engrave aluminum sheets. The process entails removing a portion of the material from the surface by utilizing acid or a laser with substantial power. This technique allows for the creation of detailed designs, patterns, or even textual elements on the aluminum sheet. The applications for etching or engraving are diverse, including signage, decorative items, and industrial components. To achieve the desired appearance, color or other finishes can be added to further enhance the resulting design on the aluminum sheet.

- Q: Can aluminum sheets be used for chemical reactors?

- Yes, aluminum sheets can be used for chemical reactors in certain applications. Aluminum is known for its excellent corrosion resistance, which makes it suitable for various chemical reactions. However, it is important to consider the type of chemicals being used and their potential reactivity with aluminum. Aluminum may not be suitable for highly acidic or alkaline environments as it can react and corrode. Additionally, aluminum may not be appropriate for reactions involving certain gases or high temperatures. In such cases, alternative materials like stainless steel or glass-lined reactors may be more suitable.

Send your message to us

Painted Aluminum Sheets Price for Color Coated Aluminium Coils for Window Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords