Painted 4 X 8 Five Bar Aluminum Sheet / Treadplate (Embossed, Stucco Sheet)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

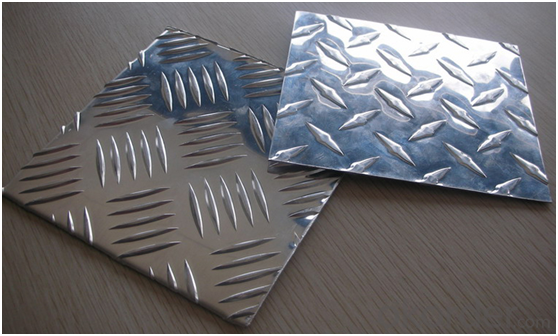

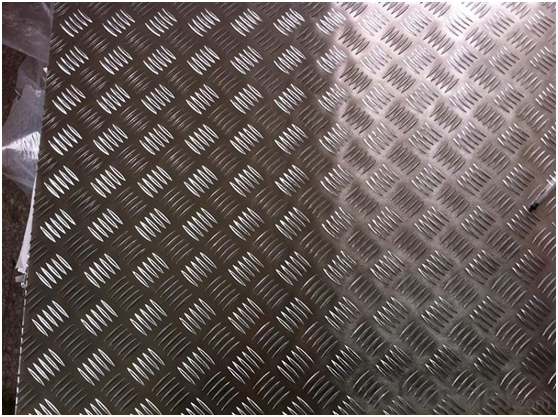

Aluminum Tread Plate

l Production Introduction

| Alloy | 1050,1060,1100,3003,3004,5052 |

| Temper | O H12 H14 H16 H18 H22 H24 H26 H32 |

| Thickness | 0.2mm-3.0mm |

| Width | 500mm-1500mm |

| Length | As your requirement |

| MOQ | 2.5MT |

| Delivery time | 15-25 days after receiving the deposit. |

| Payment | T/T 30% deposit,T/T 70% against copy of BL OR 100% LC at sight |

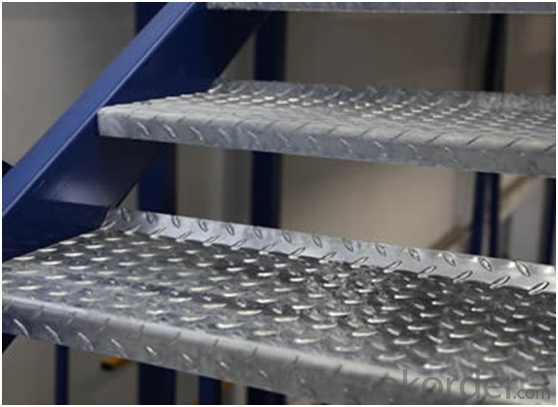

| Application | furniture, the refrigerator, air conditioning, car and platform, screen skeleton, all kinds of suspension beam, the table a foot, adornment, handle, trough and cover, chair pipe |

l Packaging & Delivery

Packaging detail: First, plastic cloth; Second, Pearl Wool; Third, wooden cases with dry agent, without fumigation, wooden pallets

Delivery detail: Within 25days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium treadplate is a popular product in CNBM. With best quality and service, we have won reputation around the world.

l CNBM World Wide

l Product Images and Application

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What can I do to remove the paint from the painted aluminum sheet?

- The aluminum need scraping, the car is not easy to enamel paint.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: Are aluminum sheets suitable for transportation applications?

- Yes, aluminum sheets are suitable for transportation applications. Aluminum is lightweight, durable, and corrosion-resistant, making it an ideal choice for various transportation components such as body panels, frames, and structural parts in vehicles, aircraft, and ships. Its high strength-to-weight ratio allows for improved fuel efficiency and load capacity. Additionally, aluminum is easily recyclable, contributing to sustainability in the transportation industry.

- Q: Are aluminum sheets non-magnetic?

- Indeed, aluminum sheets lack magnetic properties as they are not ferromagnetic. Instead, they fall under the classification of paramagnetic materials with a feeble reaction to magnetic fields. Consequently, aluminum sheets fail to exert any magnetic attraction or retention.

- Q: whst should I notice while welding aluminum sheet and aluminum block?

- two types of aluminum reach melting points, aluminum block must be preheated when you weld them with small current, you will know how to do it. You can use argon-arc welding back and forth, preheat it with small current.

- Q: Can aluminum sheets be used in the automotive industry?

- Yes, aluminum sheets can be used in the automotive industry. Aluminum is a lightweight and durable material that offers several advantages in automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, and other structural components. The use of aluminum sheets in automobiles helps to reduce the weight of the vehicle, enhancing fuel efficiency and improving performance. Additionally, aluminum has excellent corrosion resistance properties, which is crucial for vehicles exposed to harsh weather conditions. Furthermore, aluminum sheets can be easily formed, welded, and joined, making them versatile and suitable for various automotive applications. Overall, the automotive industry widely embraces the use of aluminum sheets due to their numerous benefits.

- Q: Could two pieces of aluminum sheets be welded together?

- sure, it does.

- Q: Are aluminum sheets suitable for food processing conveyor systems?

- Aluminum sheets are a great choice for food processing conveyor systems as they offer several advantages. Firstly, they are lightweight yet strong, making them perfect for conveyor systems that require frequent movement and transportation of food products. Their lightweight nature allows for easy installation, maintenance, and modification of conveyor systems, while their strength ensures the equipment's durability and longevity. Secondly, aluminum is corrosion-resistant, which is crucial in food processing environments where exposure to moisture, chemicals, and food acids is common. This resistance to corrosion ensures that the conveyor system remains hygienic and free from contamination, meeting the industry's strict food safety standards. Furthermore, aluminum is non-toxic, making it a safe material for food handling and contact. It does not react with food or release any harmful substances, ensuring the integrity and safety of the food being processed on the conveyor system. Moreover, aluminum is easy to clean and maintain, which is essential in food processing environments where hygiene is of utmost importance. The smooth and non-porous surface of aluminum sheets allows for easy removal of food particles, grease, and other contaminants, reducing the risk of bacterial growth and cross-contamination. In conclusion, aluminum sheets are highly suitable for food processing conveyor systems due to their lightweight, corrosion-resistant, non-toxic, and easy-to-clean properties. They provide a reliable and efficient means of transporting food products while ensuring the highest standards of hygiene and food safety.

- Q: What are the acoustic properties of aluminum sheets?

- Various applications benefit from the acoustic properties possessed by aluminum sheets. One key property is their lightweight composition, resulting in a high strength-to-weight ratio. This characteristic enables aluminum sheets to vibrate easily upon impact, facilitating sound transmission. Furthermore, their low density allows for sound energy absorption and noise level reduction. In addition, aluminum sheets boast exceptional corrosion resistance, ensuring their durability and longevity in diverse environments. This attribute proves particularly crucial in applications where long-term acoustic performance is essential, such as in the construction or automotive industries. Moreover, aluminum displays excellent thermal conductivity, facilitating efficient heat dissipation. This quality proves advantageous in scenarios where effective dispersal of heat generated by sound sources is necessary to prevent material damage or degradation. In conclusion, the acoustic properties of aluminum sheets, encompassing their lightweight nature, sound transmission capabilities, noise reduction effectiveness, corrosion resistance, and thermal conductivity, establish them as a versatile and dependable choice for a wide range of acoustic applications.

- Q: In which autocomponents usage of aluminium is better or otherwise?

- Aluminium is lighter as well as stronger than CI. Thats the reason most of the Automobile manufacturers use Aluminium for car bodies while they use cast iron for the underframes and internal chassis....NMN

- Q: Hello,Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum?Thanks!

- This Site Might Help You. RE: Is there a angle grinder cut off wheel made for cutting aluminum? Hello, Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum? Thanks!

Send your message to us

Painted 4 X 8 Five Bar Aluminum Sheet / Treadplate (Embossed, Stucco Sheet)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords