Packing film PVC Stretch Film

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

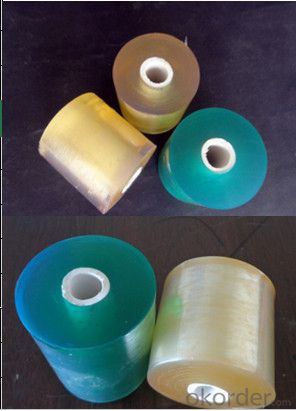

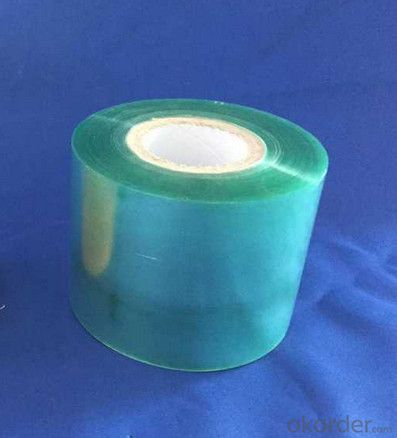

PVC Stretch Film

Material: PVC

Thickness: 18-100 micron

Width: 10-150 mm

Color: transparent, green, yellow, and so on ( The film looks colorful, but when you pull it out you will find no color, totally transparent)

Application: widely used in electrical wires, cables,various steel, precision roller, hardware accessories, furniture, building decoration materials, tourism sneakers, etc.

Feature:

1. Excellent soft

2. Good tensile resistance

3. Without secondary pollution during usage

Item No, | Thickness micron | Total roll weight | Adhesion (N/cm) | Tensile strength (Kg/cm) | Elongation |

APF-20 | 20 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-40 | 40 | 250gram/ 70mm | 1.6 | ≥300

| ≥70%

|

APF-60 | 60 | 250gram/ 70mm | 1.7 | ≥350

| ≥80%

|

APF-80 | 80 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

APF-100 | 100 | 250gram/ 70mm | 1.8 | ≥350

| ≥80%

|

- Q: What is Matt BOPP film, or matt plastic film?

- Matt BOPP for film, matte film, also called Matt Film, surface gloss is very low, depending on the sense of comfort, as the standard materials give people noble visual experience.Matte film is composed of a matte material and material prepared by CO extruded biaxially oriented, not coated.

- Q: Plastic film has eyes, how to make up?

- Using organic solvent cyclohexanone (six carbon ketone) to repair, but the best buy for repair, repair film glue (such as PVC entrail agent). The method is to first clean interface, with brush glue, dry 2-3 minutes, the film patch affixed, 2 hours after the cement can be used.

- Q: Why should farmers cover plastic film when sowing in the spring?

- The film mulching can improve the soil and ground temperature and moisture status, to improve the soil temperature, soil water content, improve soil properties and improve soil nutrient status and fertilizer utilization rate, improve light conditions, reduce weeds and pests.

- Q: What is the best plastic welding method?

- At present, the plastic welding methods use more ultrasonic welding, laser welding, hot plate welding, friction welding, vibration welding, high-frequency welding, hot air welding and induction welding. Nothing is best, just the right.

- Q: Can the concrete be covered with plastic film in summer?

- After pouring concrete, such as hot weather, air drying, maintenance is not timely, concrete in the water will evaporate quickly, dehydration phenomenon, which has formed the gel cement particles can not be fully hydrated, can not be converted into stable crystalline, the lack of sufficient bonding force, which will appear on the surface of the concrete spalling flake or powder the influence of concrete strength. In addition, when concrete does not have enough strength, the premature evaporation of water will cause greater shrinkage deformation, and dry shrinkage cracks will affect the integrity and durability of concrete.

- Q: Do I need to tear the plastic film of the barrel washing machine?

- If the paste is suitable, and does not affect the appearance, it is recommended to retain.This is actually similar to the mobile phone foil, how much of the surface a little protection, originally in order to produce the process of placing scratches.

- Q: Would you please put a plastic film on the bottom of the tent and put a plastic film on the top of the tent for lightning protection?

- Plastic film is waterproof and non-conductive, and if you can completely guarantee the insulation inside and outside the tent, then even if there are arcs outside the tent, it doesn't matter to you. So, in that case, it still works.

- Q: FFS plastic film bags are injection type?

- Tube film (blown film process) has become the best production method of FFS bag film products. FFS bag blown film technology is divided into single layer extrusion and multi layer extrusion technology according to its product form. Their production principle is basically the same, mainly equipment is different.

- Q: How to choose the plastic film for the salt packing bag?

- Well, there are two parts in your retail package. One is the inner package which is directly contacted with the salt, and the other is an outer package containing "inner packing + measuring spoon" - retail packaging? Of course, the specific design ideas you can open wider, but do not limit their thinking......

- Q: PVC plastic film, ultrasonic welding machine welding, welding can.

- When the lines are increased, the effect of welding is completely different from that of the high frequency machines. The specific performance is pale, the fastness is not enough, the lines are not good, and the holes will appear.

Send your message to us

Packing film PVC Stretch Film

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches