Packing and Lamination Film-12mic MPET/12mic PET/10 mic Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

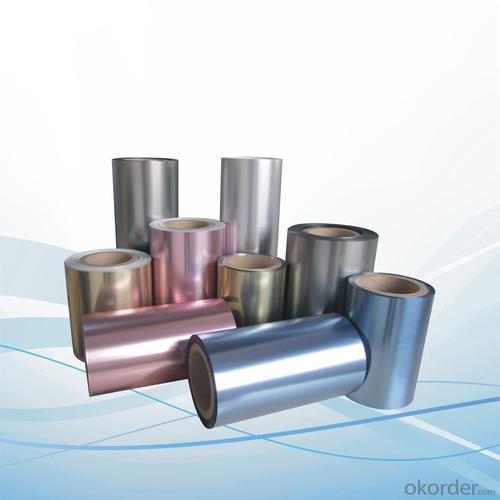

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: The material, characteristics and uses of various plastic films

- This product of EVA film blowing out the most used plastic film, greenhouse film, bags and other uses in bacteria.These products are the most common and most commonly used in our life. Both the production and sales volume are very large, and they are in use both at home and abroad.Hope to help you; if you don't understand, you can continue to ask.

- Q: Plastic film has eyes, how to make up?

- Carry on with a soldering iron or electric iron. This method is only applicable to PVC film. Repair, to shop in the film on a flat surface, cutting a hole slightly larger than the similar films, first put the two connected with a damp clothWe completely clean and dry cloth to dry film shop in the hole, then a slightly thick glass paper on top, with an electric iron in glass paper gently move, make the interface film heated to melt, when coolingAfter that, the two layers of film stick together.

- Q: What material is the film on the waterproof roll? What's your name?

- The rigid surface layer (usually 40mm thick fine stone concrete) there will be deformation of thermal expansion and contraction, if the waterproof layer and the rigid layer is very good, the rigid layer deformation will affect the waterproof layer with deformation, it may produce direct damage crack or long-term fatigue on the waterproof layer, so the isolation layer has a set of functions in the slip two tectonic layers;

- Q: What PE plastic film?

- Many PE film friends, many of them in the forefront of the operator, responsible for technology. Liquid has many PE particles, including low density, metallocene, linear and so on

- Q: Is there any toxicity in the production process of plastic blown film machine?

- There are many kinds of plastic blowing machines, such as PE, POF and so on. The scope of application of plastic film blowing machine is mainly according to the different material and set, such as the PP film blowing machine output film is suitable for all kinds of shopping bags, bags and other bacteria on the tensile and hardness of high brightness and other requirements of the bag, and high pressure PE blown film is suitable for all kinds of plastic bags, back the film material suitable for garbage bags, plastic film blowing machine is widely used in various industries.

- Q: What's the packing material for yogurt? Plastic bags, then what plastic film, and can not use carton packaging?

- Yogurt packaging (direct contact with the milk, milk is white, PE) three layer material more. Upstairs said BOPP is wrong. I've never seen a composite material for yogurt. Make the outermost layer of yogurt. BOPP composite is ok.A better one is a cup, and the PP cup is more common. Carton packaging, you go to the mall to see some, but the cost is relatively high, not necessarily for you.The cartons are not clear and should be the same or the same as the Tetra Pak products.

- Q: How to choose the plastic film for the salt packing bag?

- However, since it is a design competition, is it possible for you to design an internal and external package for the sale of edible salt? For example, are now promoting daily limit intake of salt, not excessive.

- Q: Why should a plastic film be added to the new cement road?

- The maintenance of concrete, according to the thermal calculation, concrete internal and surface temperature is less than 25 degrees, concrete pouring time after surface covered with a layer of plastic film insulation, timely prevent the conservation of water caused by excessive temperature difference between inside and outside the concrete temperature crack.

- Q: Why should plastic film be compounded? What are the composite soft packing substrates?

- Composite plastic soft packing commonly used are: transparent, color, black and white or color printing plastic composite film packaging, aluminum plastic composite film packaging, metal foil composite plastic film packaging, paper plastic film packaging.1) PE film, polyethylene, flexible packaging, more than 70% of the material is to use PE.2) BOPP film is biaxially oriented polypropylene, which is used in soft packaging3) PET films are polyester films used for printing and compounding4) CPP film, cast polypropylene film with heat sealing property5) PA film, that is, nylon film, barrier high6) PVDC film, barrier high, commonly used in sausage casings membrane7) PEN films are superior to PET in performance, but in view of price problems, there is no large-scale application.8) EVOH coextrusion film, through the EVOH and PE and PP and other coextrusion formed high barrier film9) aluminized film, high resistance film on the surface of PET, BOPP and CPP film.

- Q: Can plastic film protect against ultraviolet rays?

- Ultraviolet light refers to the electromagnetic spectrum in the wavelength from 10nm to 400nm radiation of the general term, can not cause people's vision. 1801 German physicist Ritter found to be able to make the silver containing photographic plate on the outside of the violet end of the sunlight spectrum section, and discovered the presence of ultraviolet light. Ultraviolet rays can be used to sterilize, and excessive UV rays can cause skin cancer in the body.

Send your message to us

Packing and Lamination Film-12mic MPET/12mic PET/10 mic Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches