Mylar Lamination Film- 60mm Width Metalized PET/Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

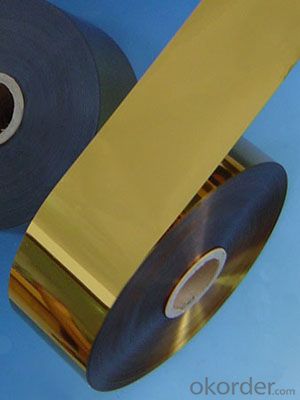

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Which plastic film is more suitable for making heat shrinkable labels?

- Need to blank, QS logo for color requirements, bar code is required for the blank area, height can be adjusted. But not less than GB 1/3.

- Q: Is there any material in the strong film made of plastic material which is resistant to high temperature, piercing, and has high tensile properties and can not tear off the film?

- High temperature resistance, piercing resistance, and high tensile properties, tear, all these properties of the film should be LLDE film.

- Q: Why should farmers cover plastic film when sowing in the spring?

- The film mulching can improve the soil and ground temperature and moisture status, to improve the soil temperature, soil water content, improve soil properties and improve soil nutrient status and fertilizer utilization rate, improve light conditions, reduce weeds and pests.

- Q: UV ink coated on plastic film, LED light cured, wrinkled, and what is the reason?

- UV ink should be baked with ultraviolet light, LED light source is wrong?

- Q: What's the best way to eliminate static electricity with plastic film?

- Electrostatic elimination is the most complete solution, according to the breadth of the film, in the serious static place, use the appropriate length of the 3024 DC pulsed ion rod, local collocation SS2000 in addition to static rope (cost saving).

- Q: What is film capacitor?

- According to the kind of plastic film is divided into: poly ether capacitor (also known as Mylar capacitor), polypropylene capacitor (also known as PP capacitor), polystyrene capacitor (also known as PS capacitor) and poly carbonate capacitor. The structure of capacitor and the same medium, polyester or polystyrene etc.. Polyester film capacitor has high dielectric constant, small volume, large capacity and good stability. It is suitable to be used as bypass capacitor. Polystyrene film capacitors, dielectric loss, high insulation resistance, but the temperature coefficient is large, can be used in high frequency circuits.

- Q: Will iron make any pollution when it is melted again?

- Like the plastic film made of polyethylene, polypropylene, EVA and other plastic is generally non-toxic, widely used in food packaging industry. And PVC plastic plastic film due to the addition of stabilizers containing lead and cadmium, it is harmful to humans, but if the use of PVC non-toxic formula (using non-toxic stabilizer and plasticizer, etc.) made of plastic film can be used for food packaging.

- Q: What are the factors affecting the puncture strength of plastic film?

- The specific operation is as follows: the diameter of test piece 100mm is installed on the fixed clamping ring like membrane, with a diameter of 1.0mm spherical apex radius of 0.5mm needle, thorn to the top with the speed of 50mm/min, the maximum load test piece read needle penetration. I hope I can help you.

- Q: How to identify the model of plastic greenhouse film?

- Should be 7.5-8 meters, we span 6 meters, with 7.5 meters, just right, both sides can be stuck, 8 meters, a little more.

- Q: How to choose PE plastic packing film

- The barrier properties of plastic film to prevent performance of oxygen, carbon dioxide, nitrogen and other gases, water vapor and aroma substances through, without clear scope, more commonly refers to oxygen, carbon dioxide, nitrogen and other non-polar gas barrier. The effect of plastic film on the display of goods is closely related to the transmittance, haze, gloss, antistatic and printing properties of the film itself. It is necessary to pay enough attention to the light transmittance and fog.

Send your message to us

Mylar Lamination Film- 60mm Width Metalized PET/Polyethylene

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords