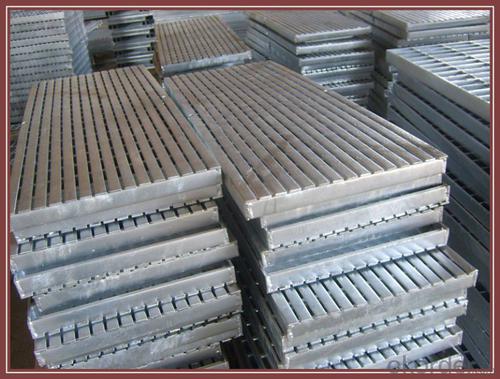

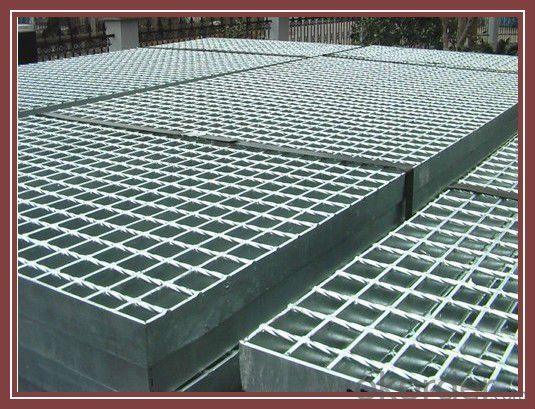

Zinc Aluminum Outdoor Aluminum Alloy Gratings Manhole Cover/Srain Trench Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum sheets be used for cookware?

- Yes, aluminum sheets can be used for cookware. Aluminum is a popular material for cookware due to its excellent heat conductivity and lightweight properties. Aluminum sheets are often used as the base or core material in the construction of cookware, such as pots, pans, and baking sheets. They are typically coated with a nonstick or ceramic layer for added durability and ease of use. However, it is important to note that pure aluminum is reactive with certain acidic or alkaline foods, which can cause a metallic taste or discoloration. To prevent this, most aluminum cookware is anodized or coated to create a barrier between the food and the aluminum surface. Overall, aluminum sheets are a versatile and commonly used material for cookware in both professional and home kitchens.

- Q: What is aluminium oxide sheet?

- The oxidation of aluminum in natural and chemical oxidation, and oxidation of several, generally refers to the chemical oxidation oxidation plate plate, is the use of chemical reaction to aluminum formed on the surface of a white coating can reach the anticorrosion effect, can also be made, through technology, color, color, texture

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: Is aluminum sheet resistant to UV rays?

- Indeed, aluminum sheet exhibits resistance to UV rays. By nature, aluminum develops a safeguarding oxide layer which functions as a shield against UV radiation. This protective layer aids in safeguarding the aluminum sheet from harm or deterioration caused by the sun's UV rays. Consequently, aluminum sheet proves to be an appropriate material for outdoor usage, enduring extended exposure to sunlight without experiencing fading or deterioration. Moreover, the reflective characteristics of aluminum also contribute to its resistance against UV rays, as it can effectively reflect a considerable portion of the sun's rays, diminishing heat absorption and the likelihood of damage.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- the fourth statement.

- Q: Can aluminum plate resist acid and alkali?

- The metal oxide film changes the surface state and properties, such as surface coloring, corrosion resistance, abrasion resistance and hardness, and metal surface protection. For example, aluminum anodizing, the aluminum alloy placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, under certain conditions and applied electricity under the electrolysis. Anodized aluminum or its alloy, formed on the surface of alumina thin layer, its thickness is 5~20 microns, anodized aluminum or its alloy. Therefore, the surface hardness and wear resistance of the aluminum alloy were greatly improved by the treatment process.Shanghai Ai Li AI metal materials, dedicated to serve you.

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a non-toxic and non-reactive metal that does not leach harmful substances into food. It is widely used in the food industry for packaging, cooking utensils, and food storage containers. Additionally, aluminum exhibits excellent heat conductivity and can be easily cleaned, making it a popular choice for food-related applications.

- Q: What characteristics distinguish aluminum sheets from other types of sheets?

- <p>Aluminum sheets are lightweight, corrosion-resistant, and have excellent thermal and electrical conductivity. They are commonly used in construction, automotive, and packaging industries. In contrast, other types of sheets, such as steel sheets, are heavier and stronger but less resistant to corrosion. Plastic sheets are lightweight and flexible but have lower strength and thermal conductivity. Copper sheets offer high thermal and electrical conductivity but are more expensive and less resistant to corrosion than aluminum. Each type of sheet has unique properties that make it suitable for specific applications.</p>

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved. Etching or engraving on aluminum sheets is a process that involves removing some of the material from the surface using acid or a high-powered laser. This can be done to create intricate designs, patterns, or even text on the aluminum sheet. The etching or engraving process can be used for various applications, such as signage, decorative pieces, or industrial parts. The resulting etched or engraved design on the aluminum sheet can be further enhanced by adding color or other finishes to create a desired look.

- Q: Are aluminum sheets resistant to chemicals?

- Aluminum sheets, in general, possess resistance to a wide range of chemicals. This is due to the presence of a natural oxide layer on the surface of aluminum, which acts as a protective shield against corrosion and chemical reactions. The stability of this oxide layer enables it to withstand the effects of most acids, alkalis, and organic solvents. However, it should be noted that certain chemicals, such as strong acids or bases, as well as some halogenated compounds, have the capacity to corrode aluminum. Moreover, prolonged exposure to particular chemicals or extreme conditions may compromise the integrity of the oxide layer, rendering aluminum more susceptible to corrosion. Consequently, when considering the use of aluminum sheets in specific applications, it is crucial to carefully evaluate the chemical environment and potential interactions.

Send your message to us

Zinc Aluminum Outdoor Aluminum Alloy Gratings Manhole Cover/Srain Trench Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords