Customized Widely Used Competitive Price Spunlace Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

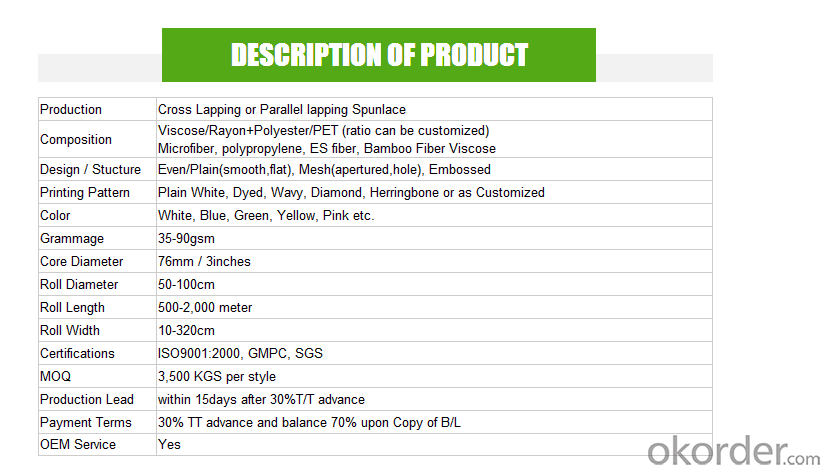

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What is the textile project

- At the same time, due to professional adjustment, graduates employment more widely, more and more graduates to enter the employment of large companies in other industries, many graduates were joint ventures, wholly-owned enterprises employed, some graduates were employed abroad, directly to overseas employment The

- Q: Lin is what kind of textile

- For jacquard fabric, can not be hard brush scrubbing, to prevent yarn breakage. 3, cotton fabric with good physical and chemical properties, but also should not be soaked in the washing solution for too long, exposure time can not be too long to prevent the destruction of color. 4, cotton fabric easy to float color, washing to prevent string dyeing and pick color, affecting the fabric appearance.

- Q: Textile printing and dyeing process which

- Dyeing long car is divided into two parts, before the car dyeing, after the car fixing color. Dyeing method according to the choice of different varieties of dyes are different, dyes are generally active, Shihlin, vulcanization, paint. They have their own advantages and disadvantages, under normal circumstances to see the color requirements, and can not replace each other.

- Q: How to make fibrous textiles for waste plastic bottles?

- Plastic bottle is a treasure, you can also make quilts, sofas, mattresses and other home textiles fillers, can also be used to make carpets, imitation and down products

- Q: Antistatic fabrics of textile electrostatic materials

- Textile materials are electrical insulator materials, generally higher than the resistance, especially the low moisture absorption performance of polyester, acrylic, polyvinyl chloride and other synthetic fibers. Therefore, in the textile processing process, due to fiber and fiber or fiber and the machine between the close contact and friction

- Q: Clothing and processing and processing into what auxiliaries

- Textile processing used a lot of additives, spinning from the spinning machine will be used, and then to the weaving, weaving need to sizing the sizing, sizing will also use a variety of additives to increase serous duct toughness

- Q: Textile enterprises to operate the project: processing and production are different?

- And production from the beginning of raw materials, such as from the thread to the weaving, made of cloth and then made into clothes.

- Q: tera textile processing where to learn

- TERA in the textile is to collect the fiber obtained by processing can be made of clothing materials technology, with the increase in proficiency can produce high-quality silk.

- Q: What are the knowledge and abilities of the Merchants in the textile industry?

- You need to report to your superiors and propose a solution to the need to integrate the available resources to help the list in place.

- Q: What is the earliest textile raw material?

- Chinese ancient textile, the use of hemp, silk, wool, cotton fiber as raw material, spinning (spinning sand, performance, reeling) processed into yarn after weaving (woven) and woven fabric, usually called textile

Send your message to us

Customized Widely Used Competitive Price Spunlace Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches