High Quality Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

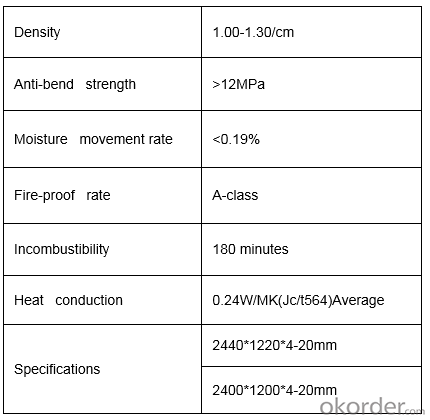

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with following factors: working temperature, bulk density, dimension (length*width*thickness), and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

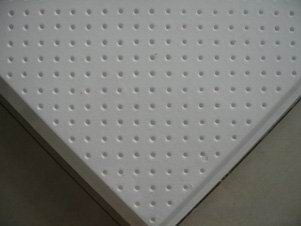

Images:

- Q: Calcium sulfate anti-static flooring and calcium silicate board What are the differences

- Calcium silicate board (also known as cement particle board), is an upgrade of ordinary particleboard products, in order to ensure excellent load-bearing performance of particleboard, but also has excellent waterproof performance, fire performance, Beijing-based floor of the calcium silicate board selected from the famous Of the "dew river" calcium silicate board, without any glue composition, health and environmental protection.

- Q: Just 6mm of calcium silicate board to do smallpox will not crack

- Calcium silicate board wall solid and reliable, easy to damage rupture. Calcium silicate board using advanced formula, in the strict quality control under the production, plate wet and dry shrinkage control in the best range. Calcium silicate board has a good thermal insulation properties, 10mm thick insulation wall insulation performance is better than ordinary brick wall effect, but also has a good sound insulation effect. Calcium silicate board performance is stable, Naisuan Jian, not easy to corrosion, it will not be moisture or insects and other damage, can guarantee a long service life.

- Q: Is the screw in the calcium silicate plate spin reliable?

- Its production of materials and processes determine its hardness is high but toughness is insufficient, that is usually said to be too brittle. So it is slightly better than the performance of gypsum board, but still only as a surface decoration materials and not as a bearing structure. Usually with most of the use of light steel keel or blockboard. In this case, the screw through the calcium silicate board into the light steel keel or blockboard in order to reliable fastening.

- Q: What is the difference between gypsum board and silicon calcium board?

- Calcium silicate board, the main component is calcium silicate, people to lime (all kinds of calcium materials can be used, such as cement, etc.), quartz powder (all kinds of siliceous materials can be used) as the main body to fiber as augmented Material mixed with water made of slab, and then by the autoclaved curing made of lightweight plate called calcium silicate board.

- Q: Buy the house is fine decoration, wood flooring poor quality to tile bathroom ceiling is calcium silicate board, it is necessary to replace it? Need to change the material of the ceiling?

- Now the basic use of aluminum ceiling plate, self-cleaning sheet can guarantee not afraid of oil, not afraid of water stains, not afraid of smell, it is important through the keel and ceiling plate between the connection, structural safety

- Q: How do I distinguish between calcium silicate boards and asbestos? I heard some people use cement board instead of calcium silicate board, containing asbestos ingredients!

- Asbestos harm to the human body: Asbestos itself is not toxic, its greatest harm comes from its fiber, which is a very small, almost invisible fibers, when these small fibers can be released after a long time floating in the air, was inhaled into the body, Inhaled asbestos fibers can accumulate in the human body for many years, attached and deposited in the lungs, causing lung disease. Asbestos is a fiber structure of silicate, in the building materials industry, mainly used for insulation materials and certain building materials, such as asbestos cement products, reinforced materials.

- Q: What is the difference between inorganic silicate composite board and inorganic calcium silicate board?

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. Is a good performance of the new building and industrial sheet, its products fire, moisture, noise, insect moth, durability is better, is the ceiling, cut off the ideal decorative plate.

- Q: What is the difference between perforated calcium silicate wallboard and gypsum board?

- Silicon calcium board was first used in high temperature furnace insulation. Such as "in order to improve the quality of shaft kiln clinker material, easy to coal blending and reduce clinker burning coal consumption, we must strengthen the kiln kiln body insulation.Often the practice is to use the internal insulation method, refractory layer, the total thickness of the insulation layer should be ≥ 650mm, near the kiln wall should be added ≥ 60mm calcium silicate board or aluminum silicate fiber mat ".

- Q: Will silicon calcium plate become moldy?

- Short time water seepage, and timely drying, keep the ventilation is not mildew. If there is easy to mold the impurities inside the silicon calcium board and glue, and in the long-term humid, non-ventilated environment, it may be mildew.

- Q: Is asbestos is a carcinogen, chrysotile calcium carbonate board can be used in public buildings?

- (N) or non-asbestos fiber reinforced general board (N) or asbestos fiber reinforced senior board (GA). General building can be used asbestos fiber reinforced ordinary Plate (A). Food processing, medicine and other buildings within the wall, should not use asbestos-containing sheet

Send your message to us

High Quality Calcium Silicate Board Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords