New Style PVC Edge Banding for MDF / Particle Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

Type: Edge Banding

Place of Origin: Shandong, China (Mainland)

Model Number: ST8050

Packaging & Delivery:

Packaging Details: standard export sea worthy packing

Delivery Detail: 7 days

pvc edge band

Quick details:

Width 12~120mm or as customer require

Thickness: 0.4-3mm or as customer require

Material: Acrylic, PVC or ABS, environment friendly material as you required

Surface: Solid color, wood grain color, glossy surface or emboss surface

Packing way: thick≤ 1mm: 200m/R, 10R/BOX; thick >1mm: 100m/R, 5R/BOX

Payment term: T/T, or L/C at sight

Advantage:

1.High and low temperature and pressure resistance .

2.Excellent quality of printing ink and never fade in color.

3.No bubble on the surface and the texture is clear.

4.Marvelous quality of primer, homogeneous and never fall from the furniture.

5.Mildew proof, anticorrosive, oil resistance, non-toxic, fire resistance.

6.safety and health

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

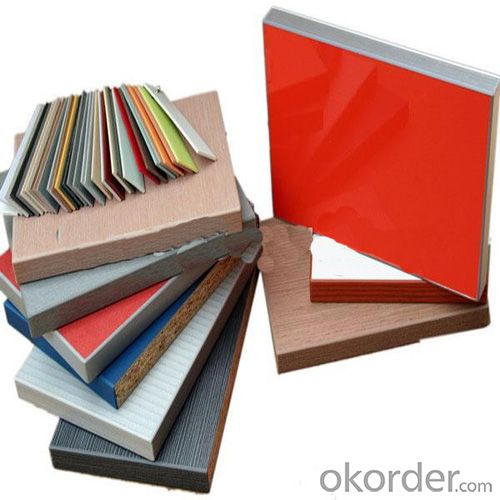

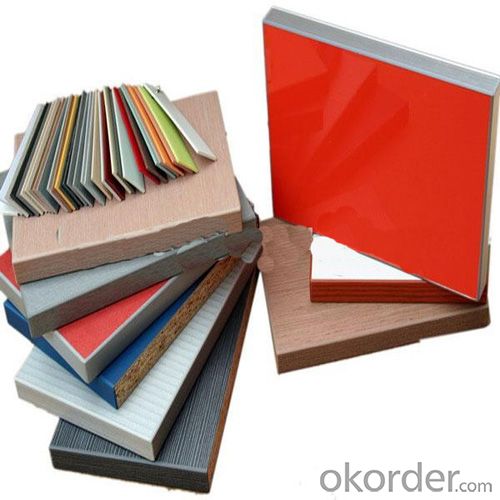

Product Show:

- Q: What kind of support is needed

- Fix the screws on the C steel

- Q: There is a phone call

- The price of polyurethane sandwich panels have the thickness of the polyurethane sandwich panels used and the color and thickness of the color steel plate to determine the price of its polyurethane sandwich panels. The common polyurethane sandwich panel specifications are 50,75,100,150,200 thick Of the price between 90-120 yuan. Manufacturers can see my picture, you need the above contact information. Here to tell you degree mother and give me a shield, and I easily I, to high score ah!

- Q: How to install the cold sandwich sandwich sandwich panels

- If the use of polyurethane cold storage board, then use the structure of the installation of the installation time can be reported to us can also install their own This is a drawing in accordance with the drawings can be installed

- Q: How do the polyurethane sandwich panels be PIR or PUR separately?

- PUR composite sheet refers to the polyurethane foam as a core commonly used is a polyether polyol, a lower isocyanate index and flame retardant formulations, the foam skeleton structure is composed of carbamate segments, the product Can only be used below 100 degrees Celsius.

- Q: Is there a requirement for the density of the steel wall

- Why choose foam sandwich panels? Know the European rock wool color plate it? European rock wool color steel plate is the steel structure of the system of energy-saving composite materials, with two high-quality color coated steel plate after forming as a panel, the use of high-quality rock wool fiber turned 90 ° after the core material Fiber and steel plate into a vertical shape), through the high strength, high viscosity of the two-component adhesive, high-quality basalt cotton and color steel plate bonding, the double-track heating and heating from the new high-end building materials The

- Q: Will the color steel sandwich panels how to install the above doors and windows how to install?

- Do not recommend yourself to get, unsafe, you can sell your people to call the master will be cheaper

- Q: How to calculate the force of the sandwich panel

- Are generally estimated that we are doing this. Do not know how to calculate, but how many people we have to do the number of board

- Q: What are the varieties of foam sandwich panels? what is the price?

- Foam sandwich panels are mainly 970 950 type 1200 ... ... OKorder Wang Teng Choi Steel Structure Co., Ltd. is a professional production of Caigang sandwich panels of the manufacturers, the company's Caigang sandwich panels have the following advantages: 1, light weight of less than 14kg weight can reduce the structural load and reduce the structural cost. Installation of the composite board baggage light weight, stitching installation and free cutting characteristics, to determine the ease of installation, can greatly improve efficiency and save time. 2, fire color composite sandwich panels of the surface material and insulation materials, fully able to meet the fire safety requirements. 3, durable a variety of studies show that, and more than 40 years abroad, widely used to confirm: the special coating of colored steel shelf life in 10-15 years, after every 10 years spray anti-corrosion coating, sheet life of up to 35 years. 4, beautiful pressure plate clear lines up to dozens of colors, with any style of building needs, to achieve satisfactory results

- Q: To do color steel sandwich panels.

- Now is the best in Sichuan

- Q: With a foam sandwich board made a 72 flat house, the cheapest how much money

- It depends on how high your house, the color plate is calculated by the board area, calculate the material about 90 or so per square

Send your message to us

New Style PVC Edge Banding for MDF / Particle Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords