FDY 1000D HIGH TENACITY INDUSTRIAL YARN Fully Drawn Yarn

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

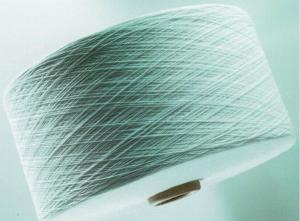

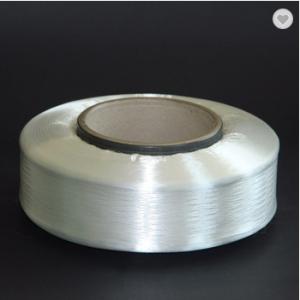

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

Specification | 11-167dtex, 12-144F |

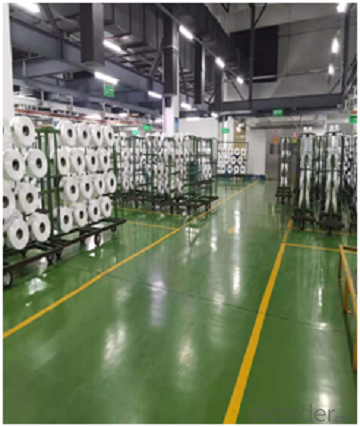

Production Facilities of FDY Yarn

We have the most advanced production system DSC. The whole production process is conducted and supervised by the operating platform. Meanwhile, there are 10 TMT fully automatic winding machine and Robot packaging system which highly improves the production efficiency and avoids manual mistakes.

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

Package of FDY Yarn

The FDY yarned is packed by plastic film, paper board, foam board and wooden pallets. Each pallets is about 640-720kg. Box package is also available.

Equipment inspection

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- 1. Processing cotton yarn manufacturing methods are more complex, in general, there are two kinds of spinning methods, that is, carded spinning and combing spinning. (1) carded spinning process: with cotton → open cotton → carding → parallel → roving → spun yarn → post-processing → finished product inspection. (2) combing spinning process: with cotton → open cotton → carding → strip → strip → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: What is the cheese yarn?

- Now some new spinning machines (such as rotor spinning, commonly known as air spinning) can be directly spun out conical or cylindrical cheese yarn.

- Q: 40s / 2 What does it mean, is this yarn 40 or 80?

- We love the veil is dedicated to do the cotton yarn, so I give you the answer is that 40 2 shares of yarn, the two lines are 40, that is, 20 per share

- Q: What is the meaning of the yarn?

- After a certain number of turns around, the jumper yarn machine automatically stops, the artificial sub-twist, tie twist, knot, loosen the yarn frame, remove the yarn

- Q: What is Artex and Artex Products?

- Analysis of the industry that, with the improvement of living standards and aesthetic concepts, foreign Artex product market will be further expanded, the development potential is huge.

- Q: What is the reason why the yarn is spinning

- The insurance yarn is woven out of cloth on the edge of 0.5 to 1 cm of the lock side, is to prevent the yarn spread out the yarn, the insurance yarn is more important than the weaving yarn

- Q: Textile yarn 75d ppt memory silk how much money meal?

- Made with its fabric soft, its performance can be comparable with silk, silky luster and comfortable feel

- Q: What is yarn support?

- The inch count is the unit weight (1 lb) of the yarn in the conventional moisture regain when the length of 840 yards multiple. A few 840 yards is the British a few yarn. (Often expressed in Ne).

- Q: Cotton yarn downstream enterprises have what kind of

- Suggest you can find, textile mills, weaving plants, silk factory, industrial cloth factory, sewing factory, etc.

- Q: Is the thickness of the yarns 40S and 80S / 2 in the textile fabric the same?

- The thickness is basically the same, but 40S is a single yarn, the general twist is Z twist, 80S / 2 is the strand, twist to S twist, is made of two 80S single yarn twisted

Send your message to us

FDY 1000D HIGH TENACITY INDUSTRIAL YARN Fully Drawn Yarn

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords