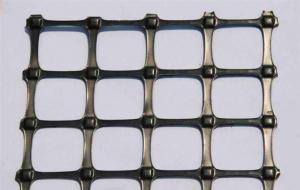

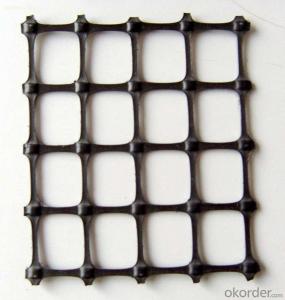

Neoloy Geocells PP Unixial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Uniaxial Plastic Geogrid for road railway highwayprojects Made from polymerand nano scale carbon black by extrusion technology

Specification ofUniaxial Plastic Geogrid for road railway highway projects:

I. TGDG35, TGDG50, TGDG80, TGDG120, TGDG160, TGDG260, TGDG300 etc

2. Lm t0 3m in roll width

Property of UniaxialPlastic Geogrid for road railway highway projects:

I. Roadbed reinforcement, improve stability and bearing capacity

2. Prevent roadbed from deformation and crack due to roadbed material wash off

3. Retaining wall bearing capacity improvement

Application of UniaxialPlastic Geogrid for road railway highway projects:

I. Roadbed reinforcement in highway

2. Municipal road, railway, airport runway

3. Dam reinforcement

4. Garden fence and river bank

5. Retaining wall reinforcement in highway

Production standard ofUniaxial Plastic Geogrid for road railway highway projects:

G B/T17689-2008

JT/T 480-2002

- Q: Can geogrids be used in reinforcement of bridge abutments on soft clays?

- Yes, geogrids can be used in the reinforcement of bridge abutments on soft clays. Geogrids are commonly used in geotechnical engineering to improve the stability and strength of soil structures. In the case of bridge abutments on soft clays, geogrids can provide lateral reinforcement and enhance the load-bearing capacity of the soil, reducing settlement and improving overall stability.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in high rainfall areas?

- Geogrids improve the performance of mechanically stabilized slopes in high rainfall areas by providing reinforcement and enhancing the stability of the soil structure. They act as a barrier against soil erosion and prevent slope failures by distributing the load more evenly. Additionally, geogrids increase the bearing capacity of the soil, reduce settlement, and improve overall slope stability, making them highly effective in managing the increased water flow and potential slope movement in high rainfall areas.

- Q: History of geotechnical materials

- Geotextiles have the following three series:A needle nonwoven geotextile, the specification of 100g/m2-600g/m2 between any choice, the main raw materials is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture method, the main purpose is to: slopeprotection River, sea, Lake embankment, land reclamation, flood control engineering, dock lock, is an effective way to maintain and prevent the piping the filter to the soil.Two, non-woven cloth and PE membrane composite geotextiles, specifications have a membrane cloth, a cloth film two, maximum width of 4.2 meters is the main raw material to use acupuncture non-woven polyester staple fiber, PE film by composite, is mainly used for seepage control, railway, highway, tunnel, subway, airport, etc. engineering.Three, non-woven and woven composite geotextiles, non-woven fabric and polypropylene filament woven fabric, non-woven and plastic woven composite, suitable for foundation reinforcement, adjust the permeability coefficient of the basic engineering facilities.

- Q: Can geogrids be used in reinforcement of soft ground?

- Yes, geogrids can be used in the reinforcement of soft ground. Geogrids are commonly used to improve the stability and load-bearing capacity of weak or soft soil by distributing the applied loads and reducing settlement. They are effective in reinforcing soft ground and can provide increased strength and stability to the soil, making them a suitable solution for various civil engineering and construction projects.

- Q: What is the typical length of a geogrid roll?

- The typical length of a geogrid roll can vary depending on the manufacturer and specific application. However, in general, geogrid rolls are commonly available in lengths ranging from 50 to 500 feet.

- Q: Manufacturers to quote the price.

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: What is the GDL geogrid

- GDL geogrid is uniaxial plastic geogrid, uniaxial plastic geogrid with high density polyethylene (HDPE) as raw materials, pressure into a sheet by extrusion and punching network rules, and then the longitudinal stretch into the geogrid.

- Q: Are geogrids resistant to corrosion?

- Yes, geogrids are generally resistant to corrosion. They are commonly made from materials such as high-density polyethylene (HDPE) or polyester, which are not prone to corrosion. This makes geogrids suitable for various applications in civil engineering and construction, where they may be exposed to moisture, chemicals, or other corrosive elements.

- Q: What are the applications of geogrids in civil engineering?

- Geogrids have numerous applications in civil engineering. They are commonly used for soil stabilization, especially in areas with weak or unstable soils. Geogrids provide reinforcement and improve the load-bearing capacity of the soil, making them ideal for constructing roads, embankments, and retaining walls. They also prevent soil erosion and help in the construction of reinforced slopes. Additionally, geogrids are utilized in the reinforcement of foundations, landfills, and land reclamation projects. Overall, geogrids play a crucial role in enhancing the durability and stability of civil engineering structures.

- Q: What are the design considerations for geogrids in mechanically stabilized earth walls?

- Some of the key design considerations for geogrids in mechanically stabilized earth (MSE) walls include selecting the appropriate geogrid material and strength, determining the required geogrid spacing and length, considering the connection and anchorage details, assessing the interface friction between the geogrid and the soil, and evaluating the long-term durability and performance of the geogrids in the specific environmental conditions. Additionally, proper installation practices and quality control measures should be implemented to ensure the geogrids are correctly positioned and tensioned within the MSE wall system.

Send your message to us

Neoloy Geocells PP Unixial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords