Geotextil Antipunzonante Needle Punched High Strength Non Woven for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Needle Punched High Strength Non Woven Geotextile:

Short fiber pet geotextile is through the non-woven production equipment of opening, carding and clutter (short fibers intertwined together), web (fixation) normalized tangles, acupuncture and other production process made of cloth.

Main Features of Needle Punched High Strength Non Woven Geotextile:

1,Good glexibilty

2,permeability

3,filtration

4,separation

5,easy for constrution

Specifications of Needle Punched High Strength Non Woven Geotextile:

1.woven geotextile(reinforced geotextile)

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~ 6m

| Packaging | packed in roll or as the customer's requirements |

| Delivery | 10 days after get the deposit |

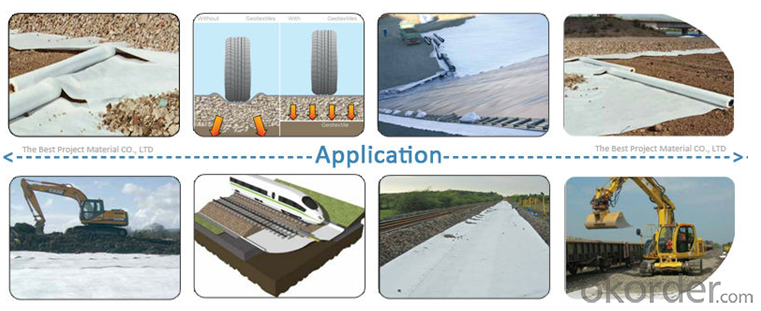

Applications of Needle Punched High Strength Non Woven Geotextile:

(1) artificial filling foundation movement of ground water.

(2) gravel filter layer surrounding the periphery of the drain pipe drain.

(3) in water conservancy projects wells, relief wells or inclined pipe filter.

(4) for retaining wall backfill reinforcement, or for anchored retaining wall panel.

(5) reinforced flexible pavements, crack repair roads, prevent the reflection cracks of pavement.

(6) in ternal vertical or horizontal drainage, dissipation of pore water pressure in soil.

(7) water impermeable geomembrane dam or embankment in the lower part of the back or the concrete.

(8) the isolation layer between the road ballast and subgrade, isolation layer or between the embankment and soft foundation.

(9) the isolation layer soil between highway, airport, railway ballast and artificial rockfill and soil fabric.

IMages of Staple Fiber Needle Punched Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Would like to know the product of the market

- Geotextile short wire geotextile, filament geotextile, polypropylene geotextile, the weight of 100g ~ 1000g per square meter range, different prices of different prices in a dollar to nine yuan range, according to the type of raw materials and specifications

- Q: Are geotextiles suitable for use in geogrid reinforced slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced slopes. Geotextiles can provide separation, filtration, and erosion control functions, which are essential for maintaining the stability and performance of geogrid reinforced slopes.

- Q: How do geotextiles improve the performance of dams?

- Geotextiles improve the performance of dams by providing various benefits such as erosion control, filtration, separation, and reinforcement. They prevent soil erosion by stabilizing the soil and preventing the loss of fine particles. Geotextiles also act as a filtration layer, allowing water to pass through while retaining soil particles. They provide separation between different soil layers, preventing intermixing and maintaining the stability of the dam structure. Additionally, geotextiles can reinforce the soil, increasing its strength and improving the overall stability and durability of the dam.

- Q: GB / T-2008 has this standard on staple geotextile? What is the exact name? Know what to say thank you!

- Yuejian Group acupuncture non-woven geotextile. It has 1. Isolation 2. Filtration 3. Drain 4. Reinforcement 5. Protection 6. Closed effect. Wang Bin

- Q: Are geotextiles resistant to earthquakes?

- No, geotextiles are not inherently resistant to earthquakes. They are primarily used for reinforcement and stabilization of soil and do not provide protection against seismic activity.

- Q: Geotextile and geogrid difference

- Different geotextile used to prevent seepage, geogrid used to reinforce the geotextile is mainly used to seepage, isolation, geogrid are generally used in reinforced reinforcement, the two are essential differences in the use of the process Sometimes used in the same project, such as high-speed, railway and other engineering production grid is made of polypropylene, polyvinyl chloride and other polymer polymer by thermoplastic or molded two-dimensional grid or a certain height of the three-dimensional Dimensional grid grid, when used as a civil engineering, known as geogrid. Engineering applications: roads, railways, abutments, approach roads, docks, dams, slag and other soft soil foundation reinforcement, retaining walls and road surface cracking engineering and other fields. Fiberglass mesh used in the external walls, wall paint, the main material to prevent the junction of different mortar and other plastering material cracking, hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Common non-woven fabrics, water layer inside the use, polyethylene polypropylene waterproof also used.

- Q: What are the geotechnical test test items for highway engineering? The

- The main inspection items are: ① Tensile strength: In the tensile test, the maximum tensile stress of the specimen up to the fracture is the tensile strength, which is called tensile strength in academia. ② elongation: elongation, that is, the percentage of the ratio of the total deformation to the length of the original gauge after the tensile fracture of the specimen. ③ tear strength: it is a thin film or thin film tear resistance of a test method defined in a term. This method is a tear test performed on a special testing machine with a specimen with a predetermined gap. ④ bursting strength ⑤ thickness ⑥ per unit area quality ⑦ permeability coefficient: permeability coefficient, also known as hydraulic conductivity. In an isotropic medium, it is defined as the unit flow rate per unit of hydraulic gradient, indicating the ease with which the fluid passes through the pore skeleton.

- Q: Can geotextiles be used in geosynthetic clay liner caps?

- Yes, geotextiles can be used in geosynthetic clay liner caps. Geotextiles are often used as a protective barrier or separator in geosynthetic clay liner systems to enhance their performance and prevent clogging or migration of fine particles.

- Q: Geotextile construction inspection batch ye do?

- Plastic woven category: the same formula, the same specifications of 100,000 square meters of products for a group; less than 100,000 square meters, the actual number of a batch. Non-woven geotextiles: the same frequency of production of the same specifications for a number of products; batch volume can be accumulated 100 volumes for a group, but the week is still less than 100 volumes of output, then with a group of output. Plastic woven cloth: batch as a unit, each batch of products randomly take 3 volumes as a sample geotextile categories: each batch of products randomly selected 2% to 3%, but not less than 2 volumes. Sample requirements: the whole width, length 3m or more, the sample can be rolled up, but can not be folded.

Send your message to us

Geotextil Antipunzonante Needle Punched High Strength Non Woven for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords