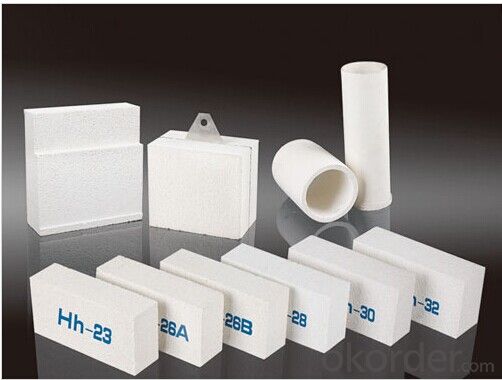

Mullite Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw material is crude highquality highalumin low ferrous content material. The unique polylight spheres producing technique is adopted. The main structure of this high-quality heat insulation refractory brick is mullite crystal phase. The characteristics of this product are:

High compression strength

Good high-temperature performance

Excellent thermal shock stability

Low thermal conductivity

Outstanding penetration resistance ability

Erosion resistance

Application:

It may be widely used as the lining and the heat insulation layer of industrial kilns in the fields of metallurgy, petrochemistry, machinery, power, ceramics, etc... It is an ideal product of long service life, energy-saving and effects-enhancing product.

| Brand

Item |

JM-23 |

JM-26 |

JM-28 |

JM-30 |

Al2O3(%)min | 37 | 50 | 60 | 68 |

Fe2O3(%)max | 1.0 | 1.0 | 0.7 | 0.5 |

SiO2(%)max | 45 | 43 | 36 | 29 |

Safty Application Temp.(°C)max | 1260 | 1430 | 1540 | 1650 |

Bulk Density(g/cm3) | 0.5 | 0.8 | 0.95 | 1.05 |

Bending strength(Mpa)min | 0.7 | 1.1 | 1.6 | 2.0 |

Crush strength(Mpa)min | 1.0 | 2.0 | 2.3 | 2.7 |

RLC(%)max | 1230°C×24h 0.3 | 1400°C×24h 0.4 | 1510°C×24h 0.5 | 1600°C×24h 0.6 |

Reversible thermal expansion at1090°C(%) max |

0.5 |

0.6 |

0.8 |

0.8 |

Thermal conductivity (w/m.k)max 400°C 600°C 800°C 1000°C |

0.15 0.17 0.19 0.24 |

0.28 0.31 0.33 0.35 |

0.33 0.36 0.39 0.42 |

0.41 0.43 0.45 0.48 |

- Q: Are insulating fire bricks resistant to erosion?

- Yes, insulating fire bricks are resistant to erosion.

- Q: Can insulating fire bricks be used in the construction of lime calciners?

- Yes, insulating fire bricks can be used in the construction of lime calciners. Lime calciners require high temperatures to produce lime, and insulating fire bricks are designed to withstand and retain heat. These bricks have low thermal conductivity, allowing them to effectively insulate the calciner and prevent heat loss. Additionally, insulating fire bricks are lightweight, making them easier to handle and install in the construction of lime calciners.

- Q: Can insulating fire bricks be used in the construction of flue gas ducts?

- Yes, insulating fire bricks can be used in the construction of flue gas ducts. These bricks are designed to withstand high temperatures and have excellent insulation properties, making them suitable for lining flue gas ducts where heat retention and energy efficiency are important.

- Q: Is it necessary to abolish the technical regulations for the construction of self thermal insulation masonry building with sludge sintering insulation bricks?

- Silt sintering brick insulation brick is made from river mud, city sludge, mud as the main raw materials, added according to a certain proportion of siliceous inorganic binder after aging, extrusion blank, blank by cutting, drying, sintering and extrusion molding machine. The utility model has the advantages of energy saving, resource saving, favorable for developing circular economy and comprehensive utilization of resources, high micropore rate, good product heat insulation performance and heat insulation performance, etc..

- Q: Can insulating fire bricks be used in the construction of radiant tubes?

- Yes, insulating fire bricks can be used in the construction of radiant tubes. Insulating fire bricks are specially designed to provide excellent thermal insulation, making them ideal for applications where heat retention is important. Radiant tubes are used in high-temperature environments, such as furnaces and kilns, where they are exposed to extreme heat. Insulating fire bricks can withstand these high temperatures and help to minimize heat loss, resulting in improved energy efficiency. Additionally, the insulating properties of these bricks can also help to protect the radiant tubes from thermal shock and prolong their lifespan. Overall, using insulating fire bricks in the construction of radiant tubes can enhance their performance and durability.

- Q: Can insulating fire bricks be used in the construction of smelting crucibles?

- Yes, insulating fire bricks can be used in the construction of smelting crucibles. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation. They are commonly used in applications that require heat retention and protection, such as kilns and furnaces. Smelting crucibles, which are used to melt and refine metals, also require materials that can withstand extreme temperatures. Insulating fire bricks are an ideal choice for constructing smelting crucibles because they can help maintain a consistent temperature within the crucible and prevent heat loss. Additionally, their insulating properties can reduce energy consumption and increase the efficiency of the smelting process.

- Q: Can insulating fire bricks be used for insulation in residential walls?

- Insulating fire bricks are typically not recommended for use in residential walls as insulation. While they are highly effective at withstanding extreme temperatures and providing thermal insulation in industrial settings such as furnaces and kilns, they are not designed to meet the specific requirements of residential construction. Insulating fire bricks have a high thermal conductivity, meaning they conduct heat more efficiently than traditional insulation materials like fiberglass or foam. This can result in significant heat loss and reduced energy efficiency in residential walls. Furthermore, insulating fire bricks are typically larger and heavier than conventional insulation materials, making them more difficult and costly to install in residential walls. They also lack the flexibility and ease of use that other insulation materials offer. For residential applications, it is recommended to use insulation materials specifically designed for residential walls, such as fiberglass batts, foam boards, or spray foam insulation. These materials are lightweight, easy to install, and provide excellent thermal insulation properties, helping to maintain a comfortable indoor temperature and reduce energy consumption.

- Q: Can insulating fire bricks be used in the construction of blast furnaces?

- Yes, insulating fire bricks can be used in the construction of blast furnaces. These bricks are made from lightweight materials with high thermal resistance, which makes them highly suitable for insulating the inner lining of blast furnaces. They help to minimize heat loss and maintain the high temperatures required for efficient and effective operation of the blast furnace, making them an essential component in its construction.

- Q: Can insulating fire bricks be used in residential applications, such as fireplaces or ovens?

- Insulating fire bricks can indeed be used in residential applications such as fireplaces or ovens. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight materials such as clay or alumina, which have low thermal conductivity. This helps to keep the heat inside the fireplace or oven, making it more efficient and reducing energy consumption. Insulating fire bricks also have good resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. Additionally, these bricks are non-combustible, ensuring they can withstand the high temperatures generated in fireplaces or ovens without posing a fire hazard. Therefore, insulating fire bricks are a suitable choice for residential applications where high temperatures and thermal insulation are required.

- Q: Do insulating fire bricks require any curing before use?

- Indeed, curing is necessary for insulating fire bricks prior to their usage. Curing refers to the procedure of drying and toughening the bricks in order to guarantee their resilience against high temperatures, preventing any potential cracking or breaking. To accomplish this, the temperature needs to be elevated gradually over a specific duration, usually commencing with a gentle heat and slowly escalating it throughout several hours. Curing is pivotal as it aids in eliminating any moisture or volatile substances that may exist within the bricks, which, if left untreated, could lead to cracking or even explosion when exposed to elevated temperatures. To ensure the correct installation and longevity of the fire bricks, it is crucial to adhere to the manufacturer's guidelines regarding the curing process.

Send your message to us

Mullite Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords